Food cold extraction manufacturing technological process

A process and cold extraction technology, applied in the field of food cold extraction production process, can solve the problem that the effect of food cold extraction is not very good, and achieve the effects of improving taste and quality, low consumption cost and retaining nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

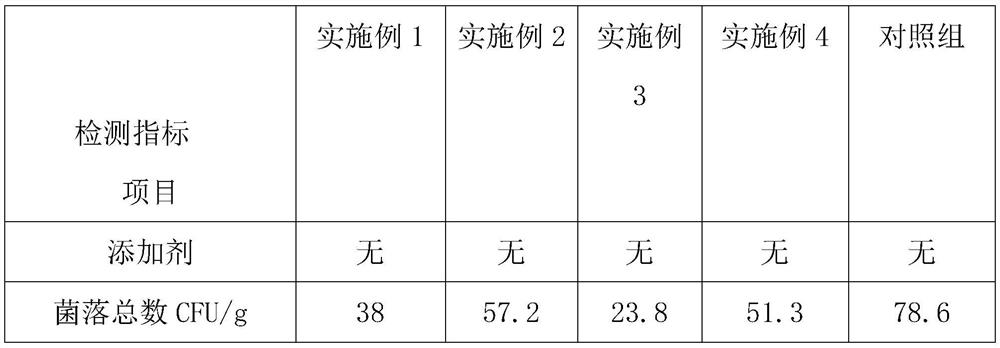

Examples

Embodiment 1

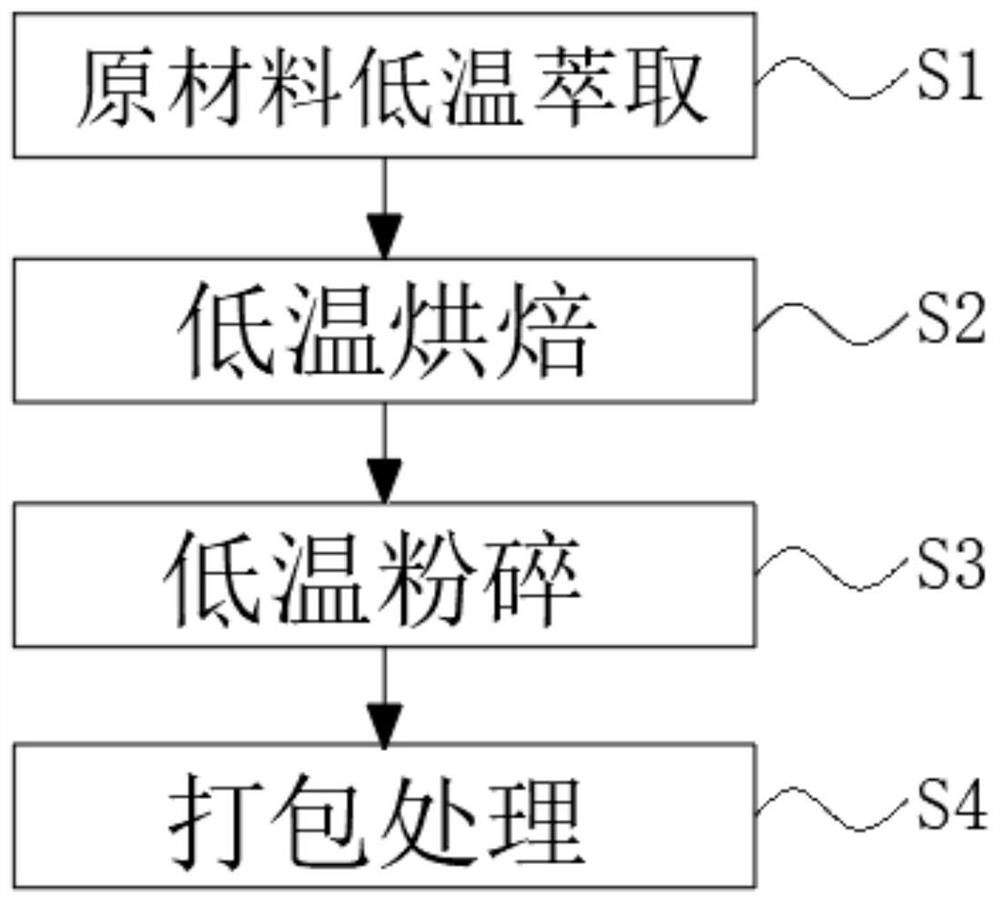

[0020] S1. Low-temperature extraction of raw materials: Put the raw materials into the container for specific low-temperature soaking and cleaning. The temperature of low-temperature soaking needs to be controlled at 0 degrees Celsius to remove some of the peculiar smell of the raw materials;

[0021] S2, low-temperature baking: the material is matured at low temperature, and the time of low-temperature baking is controlled at 30 minutes;

[0022] S3. Low temperature pulverization: pulverize the material by low temperature or vacuum liquid nitrogen;

[0023] S4. Packing treatment: Sterilize the pulverized material, randomly check the various indicators of the material, and pack it with a packing machine after passing the test.

Embodiment 2

[0025] S1. Low-temperature extraction of raw materials: Put the raw materials into the container for low-temperature soaking and cleaning. The temperature of the low-temperature soaking needs to be controlled at 5 degrees Celsius to remove some of the peculiar smell of the raw materials;

[0026] S2. Low-temperature baking: mature the material at low temperature, and control the low-temperature baking time to 90 minutes;

[0027] S3. Low temperature pulverization: pulverize the material by low temperature or vacuum liquid nitrogen;

[0028] S4. Packing treatment: Sterilize the pulverized material, randomly check the various indicators of the material, and pack it with a packing machine after passing the test.

Embodiment 3

[0030] S1. Low-temperature extraction of raw materials: Put the raw materials into the container for low-temperature soaking and cleaning. The temperature of low-temperature soaking needs to be controlled at 3 degrees Celsius to remove some of the peculiar smell of the raw materials;

[0031] S2, low-temperature baking: the material is matured at low temperature, and the time of low-temperature baking is controlled at 60 minutes;

[0032] S3. Low temperature pulverization: pulverize the material by low temperature or vacuum liquid nitrogen;

[0033] S4. Packaging treatment: Sterilize the crushed materials, randomly check the various indicators of the materials, and then pack them with a baler after passing the test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com