Rolling ball type rapid color changing paint supply system

A rapid color change and supply system technology, applied in the direction of spraying devices, etc., can solve the problems of color chromatic aberration, system cleaning difficulty, waste of solvent and paint materials, etc., to avoid color difference and improve the flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] Example 1

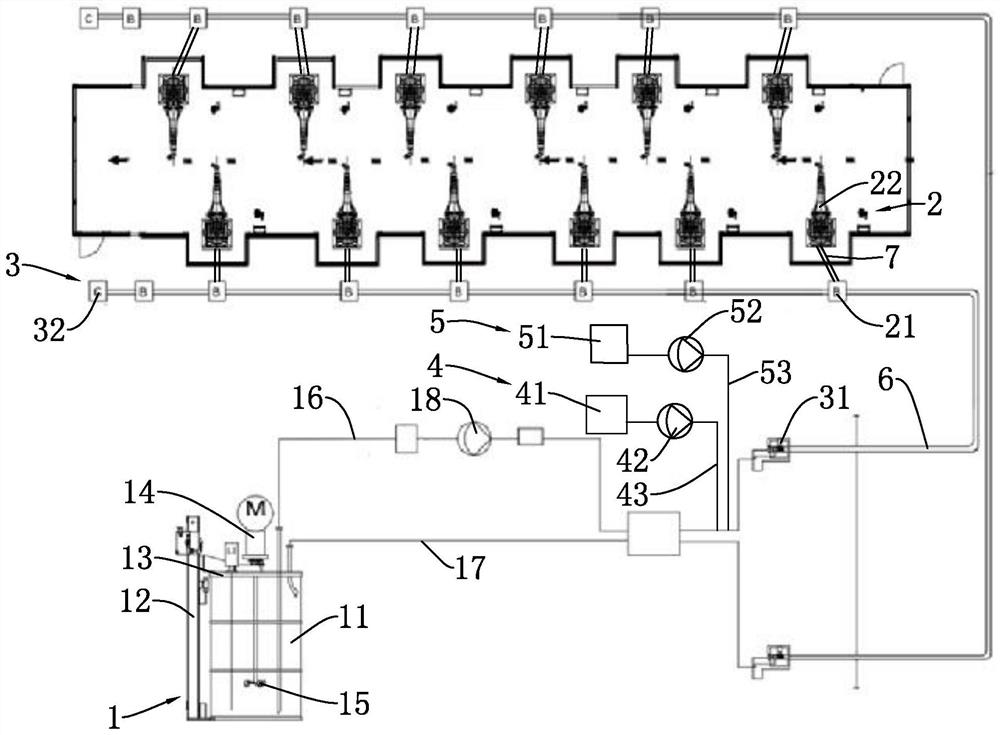

[0036] The present application example discloses an asploaded fast changing paint supply system. Refer figure 1 The bead fast changing paint supply system includes a molding unit 1, a paint unit 2, a bead recovery unit 3, a solvent cleaning unit 4, and a pure water cleaning unit 5.

[0037] Among them, the paint unit 1 includes a lacquer drum 11, a pneumatic lifting frame 12, a barrel cover 13, a stirring motor 14, and a stirring paddle 15, and the lacquer bucket 11 is supported on the ground, and the pneumatic lift frame 12 is disposed on the lacquerable bucket 11 side, bucket The cover 13 is connected to the pneumatic lift frame 12, which is driven by the pneumatic lifting frame 12 in the lid of the bucket cover 13 on the lacquer drum 11.

[0038] The stirring motor 14 is mounted on the barrel cover 13, and the output shaft extends into the lacquer drum 11 through the bucket cover 13, and the stirring paddle 15 is fixed to the output shaft of the stirring moto...

Example Embodiment

[0049] Example 2

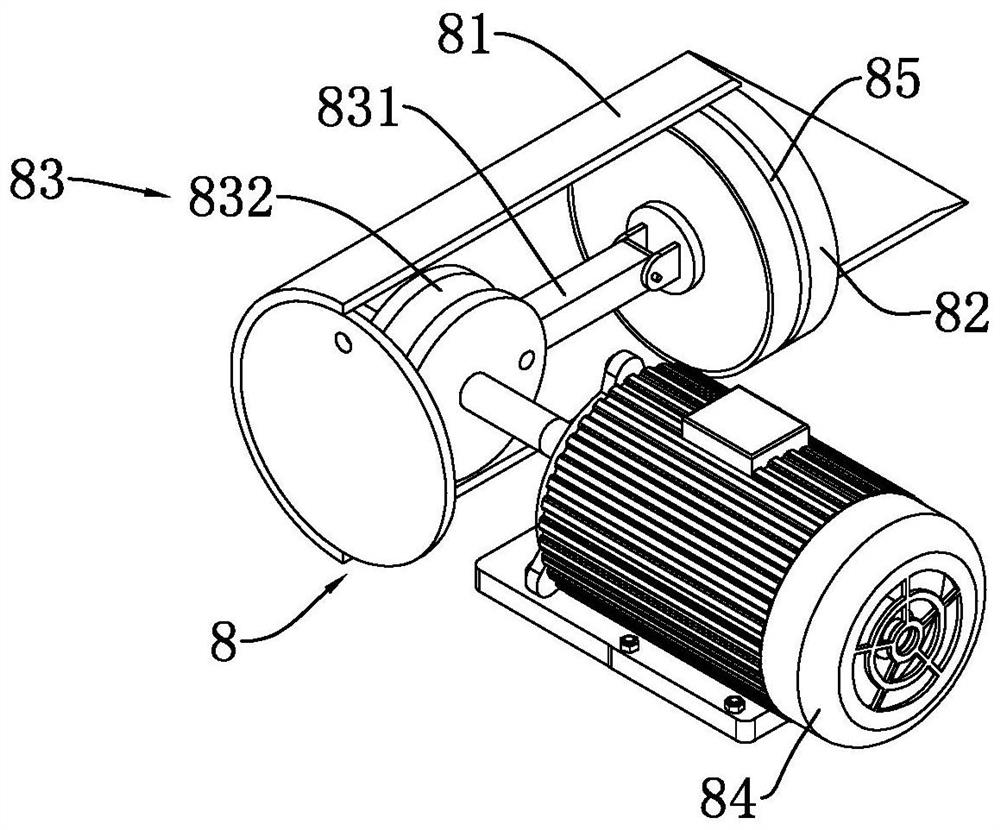

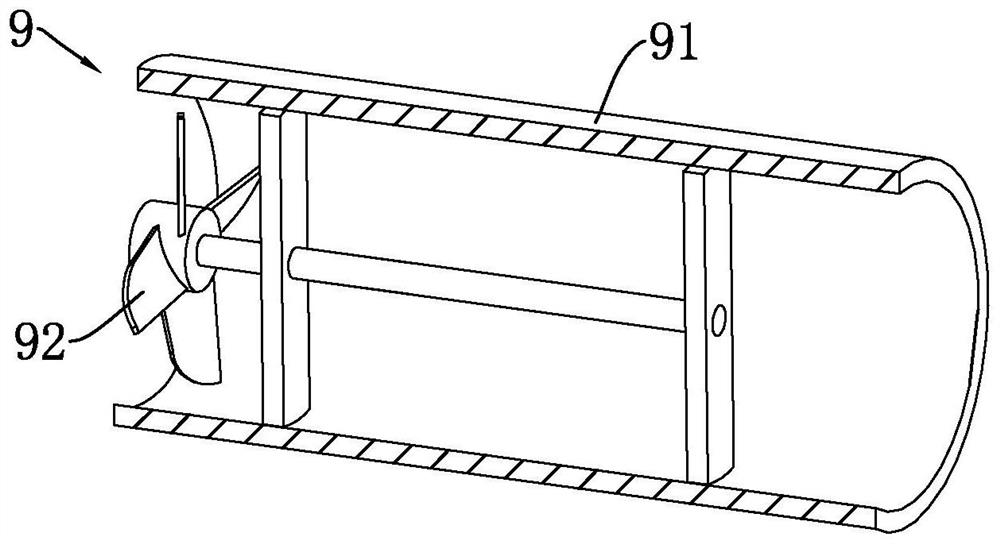

[0050] The difference between the present embodiment and the first embodiment is that the pure water cleaning unit 5 of the present embodiment further includes a pressurizing member 8 and average flow member 9 that increases the transport pressure of pure water by the charge member 8, and passes through all flow parts 9. Pure water produces a rotation, more fully cleaning paint, thereby making the replacement system more comprehensive cleaning.

[0051] Refer figure 2 The booster 8 includes a pressurizing cylinder 81, a piston 82, a connecting mechanism 83, and a drive motor 84, wherein the inclined barrel 81 is open, and the bottom of the cylinder is opened, and the booster 81 is tilted in the pure water pipe 53. On the upper, the tubular port is communicated with the pure water pipe 53; the tilt direction of the booster 81 is the same as the pure water flow direction.

[0052] The piston 82 is slidably mounted inside the booster 81, and is located at the openi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap