Coating structure capable of preventing film from wrinkling for reflective film coating machine

A technology of coating machine and film, which is applied to the device and coating of surface coating liquid, which can solve the problem of easy wrinkling of film raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

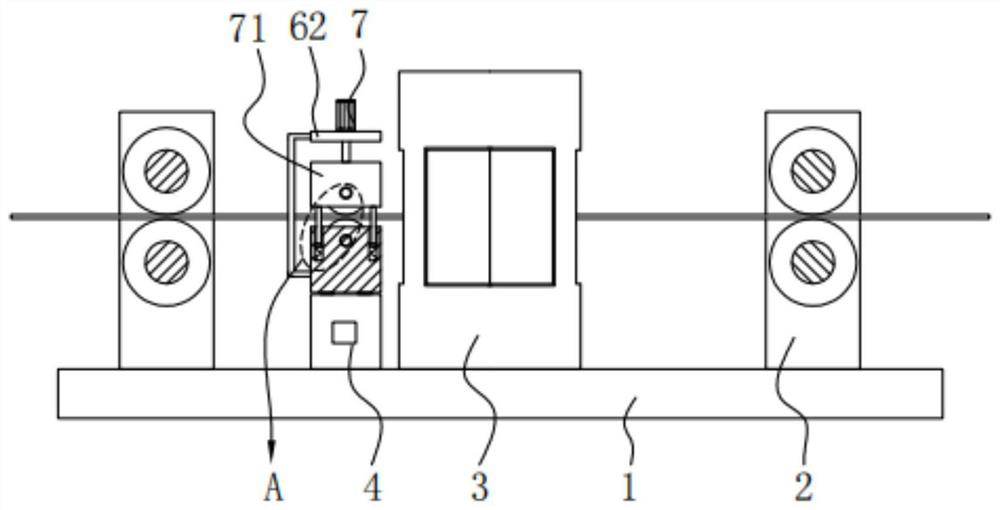

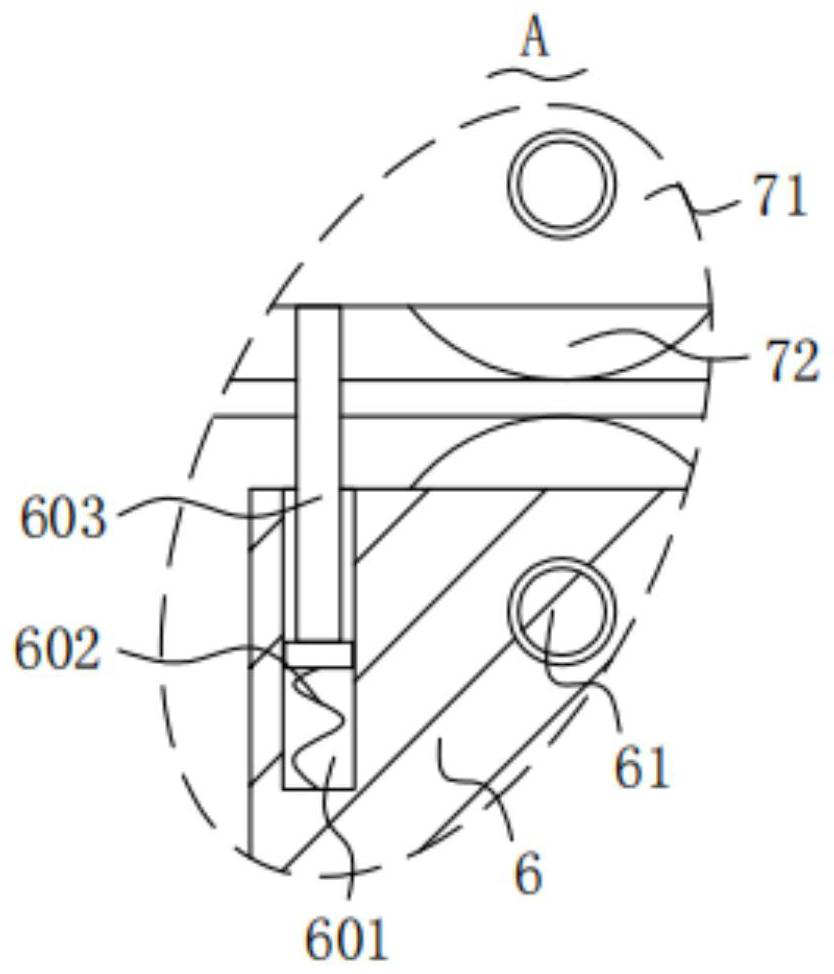

[0039] Please refer to figure 1 , figure 2 , image 3 and Figure 4 ,in, figure 1 The structural schematic diagram of the first embodiment of the coating structure that can prevent film wrinkling for the reflective film coating machine provided by the present invention; figure 2 for figure 1 The enlarged schematic diagram of part A shown; image 3 for figure 1 A three-dimensional view of the portion of the mount shown; Figure 4 for image 3 The schematic diagram of the internal structure of the fixed frame is shown.

[0040] A coating structure that can prevent film wrinkling for a reflective film coating machine includes: a mounting mechanism 1, two sets of conveying mechanisms 2 and a coating machine 3, and the coating machine 3 is installed on the top of the mounting mechanism 1, two The conveying mechanism 2 is symmetrically installed on both sides of the coating machine 3; the fixed frame 4, the bottom of the fixed frame 4 is fixedly installed on the top of th...

no. 2 example

[0061] see Figure 5 , Figure 6 , Figure 7 and Figure 8 , based on the coating structure for a reflective film coating machine that can prevent film wrinkling provided in the first embodiment of the application, the second embodiment of the application proposes another coating structure for a reflective film coating machine that can prevent film wrinkling coating structure. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0062] Specifically, the difference between the coating structure that prevents film wrinkling for a reflective film coater provided in the second embodiment of the present application is that the coating structure that prevents film wrinkle for a reflective film coater also includes:

[0063] The bottom of the fixed frame 4 offers a limit slide hole 401, the limit slide hole 401 inner wall is fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com