Metal plate alignment jig based on switch cabinet shell machining and using method of metal plate alignment jig

A technology for switch cabinets and shells, which is applied in the field of sheet metal alignment fixtures, can solve problems such as increasing installation difficulty and reducing assembly efficiency, and achieves the effect of avoiding the participation of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

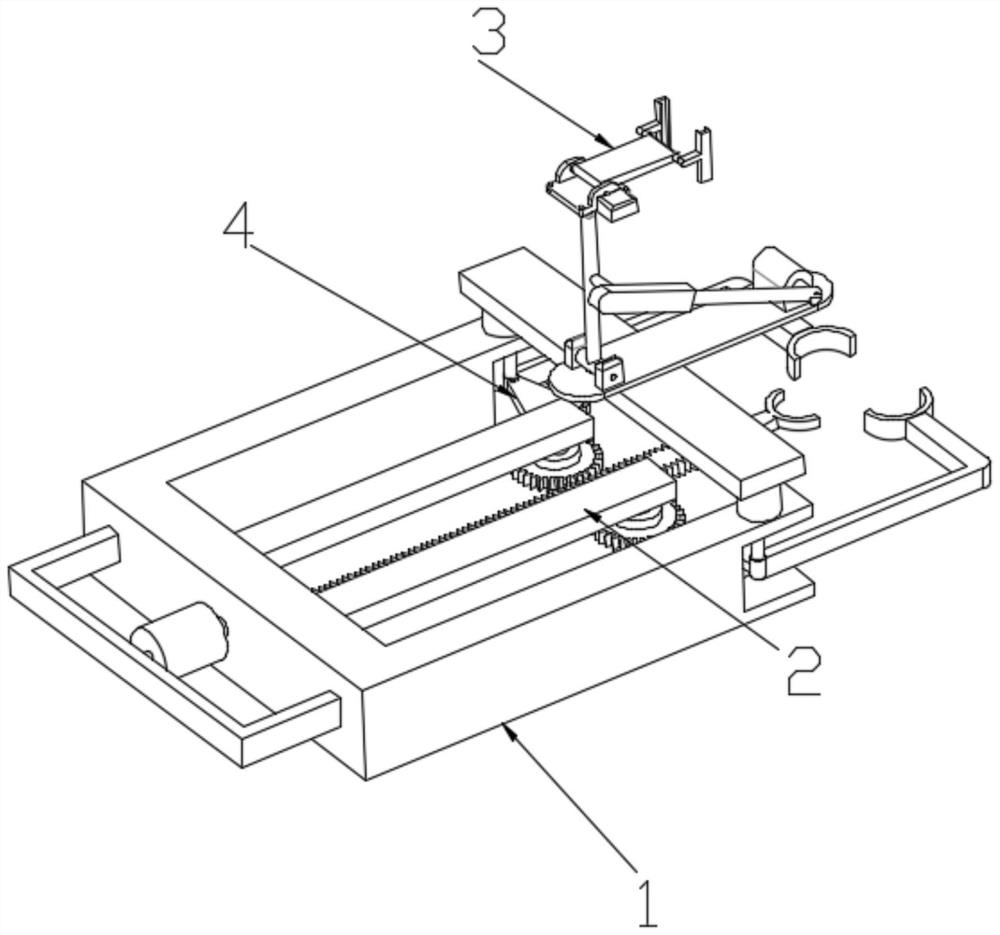

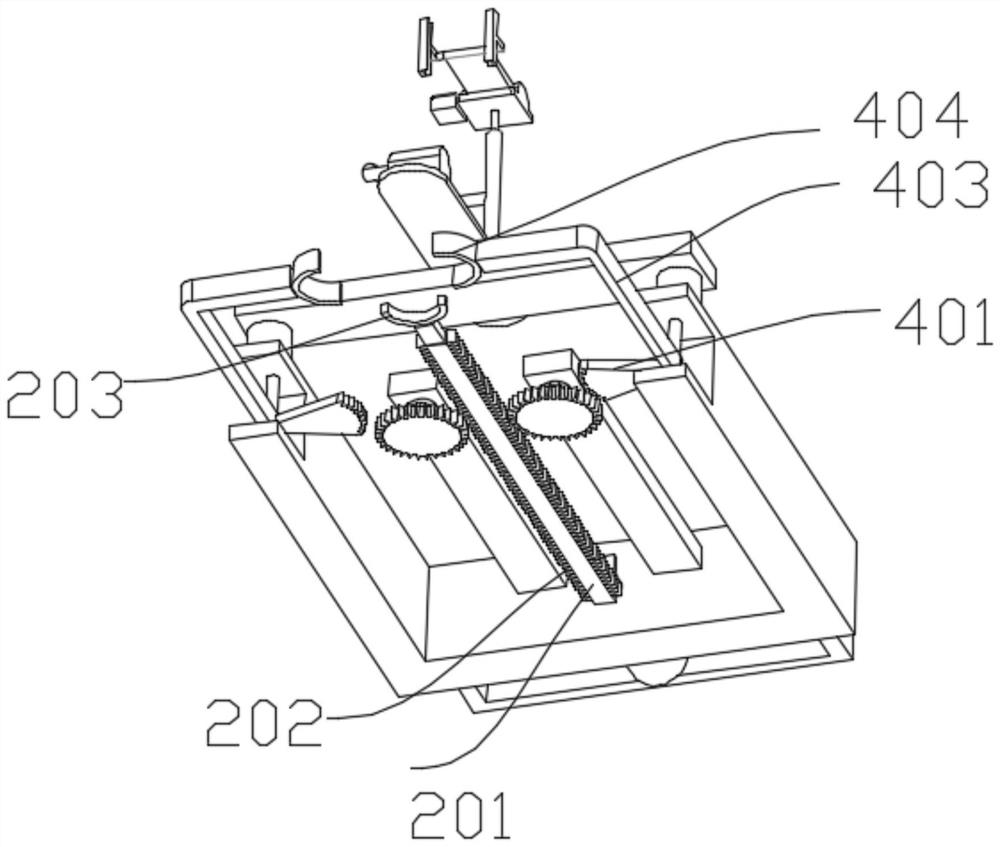

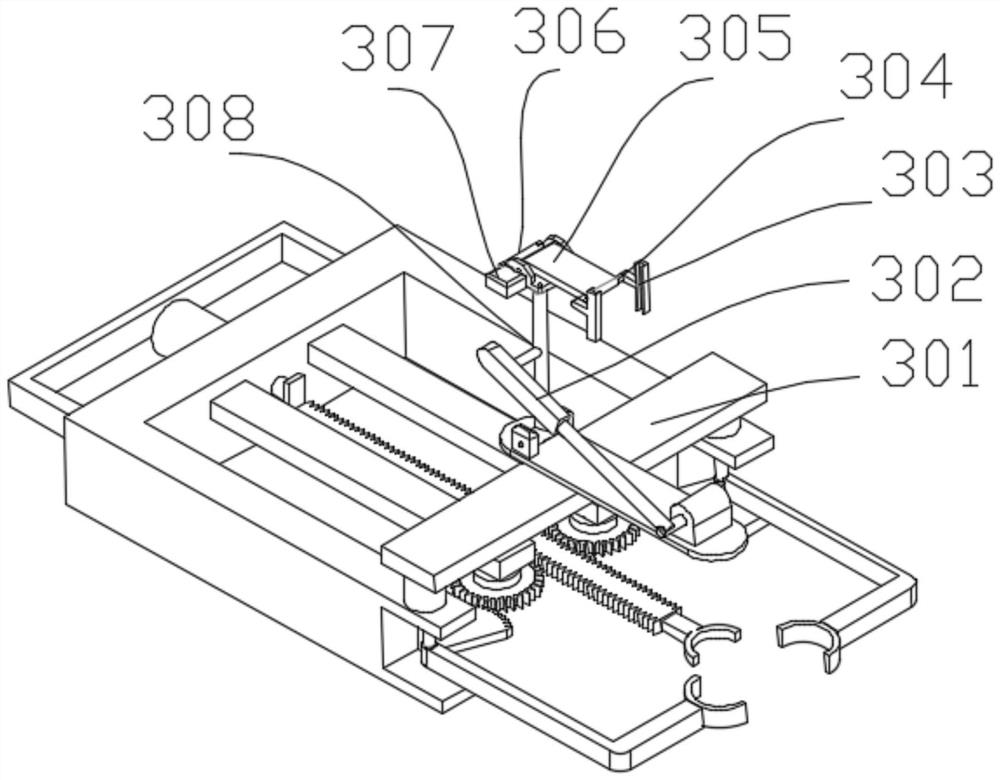

[0028] In order to facilitate the triangular fixing of the switchgear shell and improve the stability when aligning the sheet metal, refer to figure 1 , figure 2 and Figure 4 As shown, it includes an installation frame 1 with at least one end being open. The drive assembly 2 aligned with the switch cabinet shell is arranged in the installation frame 1. The drive assembly 2 includes a fixing plate 205 arranged on the outside of the installation frame 1. Inside the fixing plate 205 An electric telescopic rod 204 is provided, and the electric telescopic rod 204 extends to the installation frame 1 and is connected with a push plate 201, and the outer side of the push plate 201 is equidistantly arranged with conical teeth 202, and the side of the push plate 201 away from the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com