Anti-leakage aluminum-magnesium-manganese roof system and construction method

A roof system, Al-Mg-Mn technology, applied to roofs, roof coverings, roofs using flat/curved panels, etc., can solve problems such as roof mold, affecting the safety of the roof system, and accumulation of rainwater in the roof system to achieve a sense of hierarchy Strong, outstanding visual effects, and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

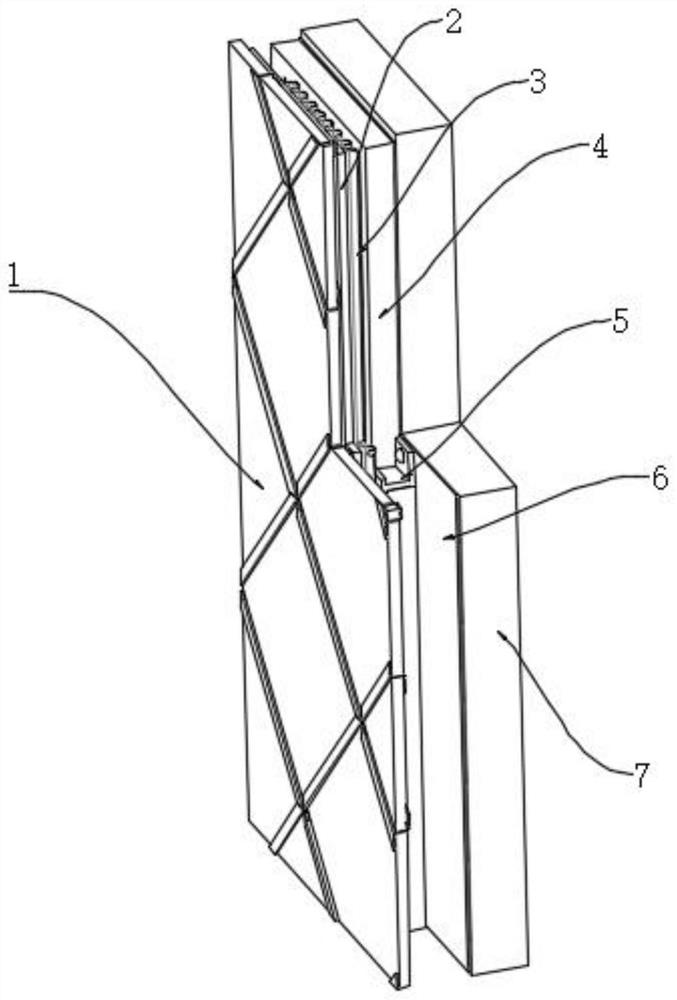

[0059] An anti-seepage aluminum-magnesium-manganese roofing system, such as Figure 1-6 As shown, it includes a screen lock buckle roof panel 1, a leveling support steel plate 2, a profiled steel bearing plate 3, an insulation layer 4, an I-shaped fixing part 5, and a civil structure layer 7; the outer wall of the I-shaped fixing part 5 is fixedly connected to the The outer wall on one side of the civil structure layer 7; the outer wall on the other side of the I-shaped fixture 5 is fixedly connected to the outer wall on one side of the profiled steel bearing plate 3; the outer wall on one side of the civil structure layer 7 is pasted with a self-adhesive waterproof coil 6; the insulation layer 4 is set on Between the profiled steel bearing plate 3 and the self-adhesive waterproof coiled material 6; the outer wall on one side of the leveling support plate 2 is fixedly connected to the outer wall on the other side of the profiled steel bearing plate 3; the outer wall on one side...

Embodiment 2

[0065] A construction method for an anti-seepage aluminum-magnesium-manganese roof system, specifically comprising the following steps:

[0066] S1: Measure the length and width of the roof on the spot;

[0067] S2: Select the standard version of the flat lock and process it;

[0068] S3: Paste the self-adhesive waterproof membrane 6 on the civil structure layer 7 and install the I-shaped fixing part 5 on the civil structure layer 7;

[0069] S4: laying the thermal insulation layer 4 on the self-adhesive waterproof membrane 6;

[0070] S5: Fix the profiled steel bearing plate 3 on the I-shaped fixture 5 and lay the leveling support plate 2 on the profiled steel bearing plate 3;

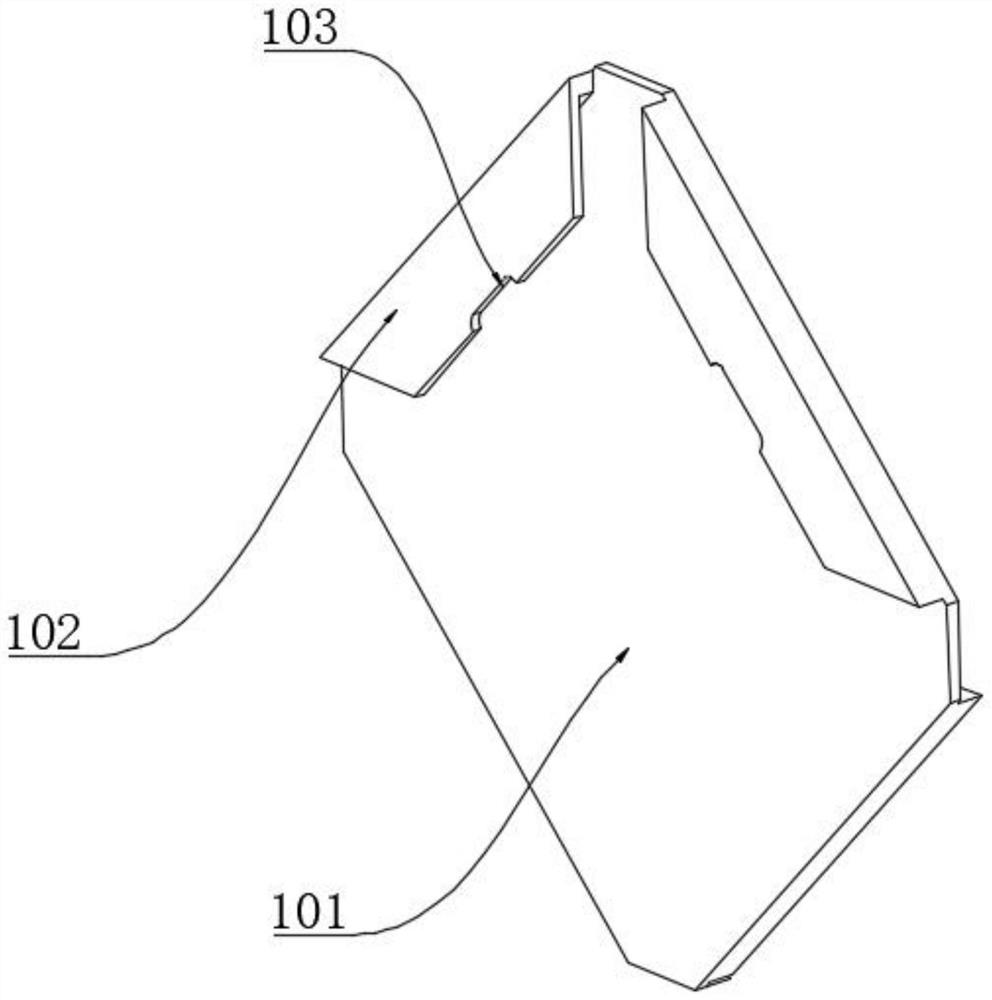

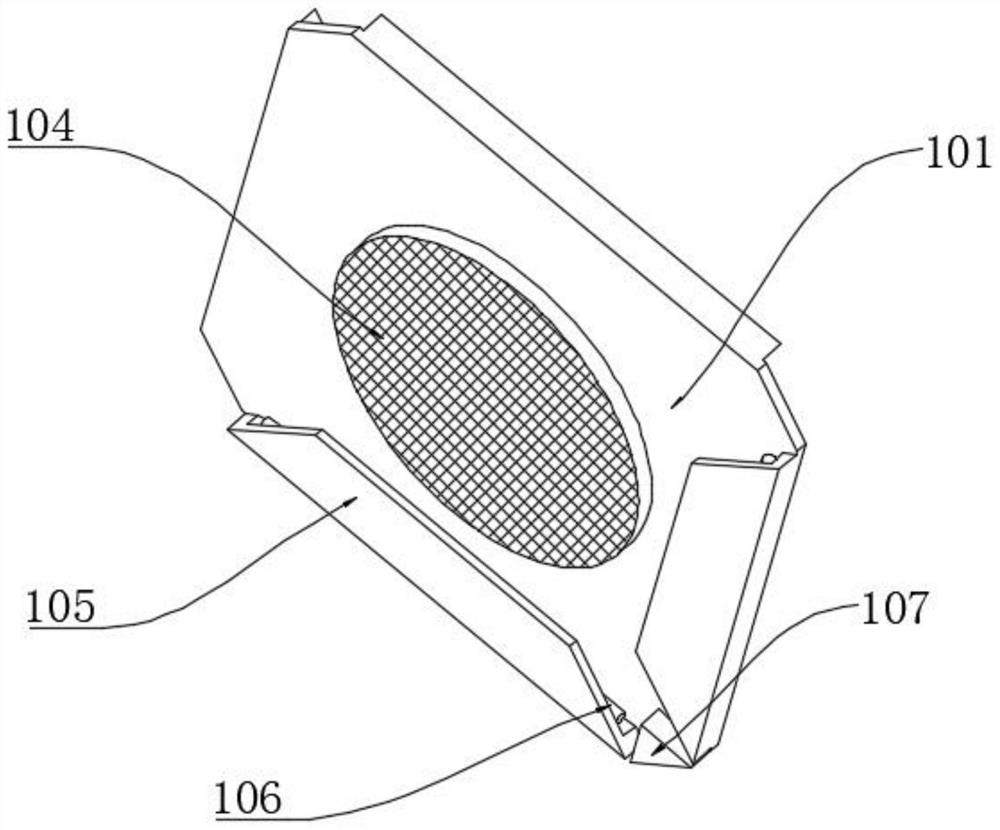

[0071] S6: Connect the screen lock roof panel 1 to each other through the first buckle connecting plate 102 and the second buckle connecting plate 105, and fix the buckle groove 103 on the first buckle connecting plate 102 through the rivet 9 On the leveling support plate 2.

[0072] In order to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com