Preparation method of phosphogypsum lightweight building block with low water cement ratio

A technology of phosphogypsum and water-cement ratio, which is applied in the direction of ice making, ice making, ceramic products, etc., can solve the problem that the water-cement ratio cannot be too high, and achieve the effects of improving turnover efficiency, satisfying strength, and reducing the amount of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

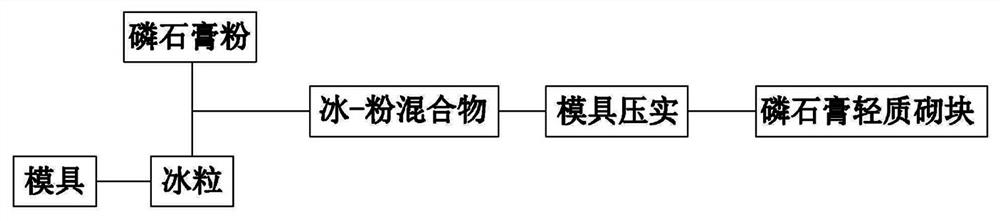

[0046] Such as figure 1 Among them, a kind of preparation method of phosphogypsum lightweight block with low water-cement ratio comprises the following steps:

[0047] s1. Prepare ice particles according to the optimal water-cement mass ratio;

[0048] In a preferred solution, the particle size of the ice particles is 0.75 cm to 2.00 cm. In a further preferred solution, the ice particles are graded ice particles, for example, 0.75cm, 1cm, 1.5cm, and 2cm each account for 25% by mass. According to the requirements of the final product, it can also be other gradation ratios, and ice with different particle sizes The grains are mixed for later use.

[0049] In a preferred solution, the water used to prepare the ice particles contains an accelerator with a mass ratio of 0.3% to 1.0%.

[0050] In the preferred scheme, the quick-setting agent includes K 2 SO 4 .

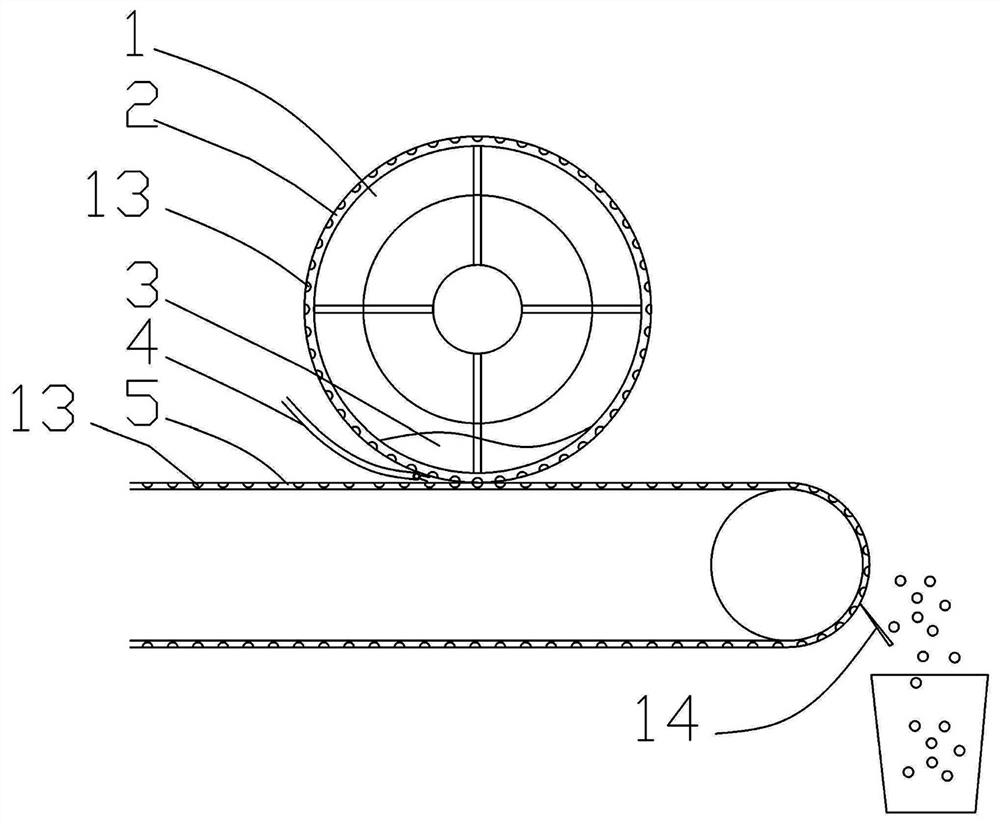

[0051] Alternative options such as figure 2 In this method, ice particles are prepared by using double-layered si...

Embodiment 2

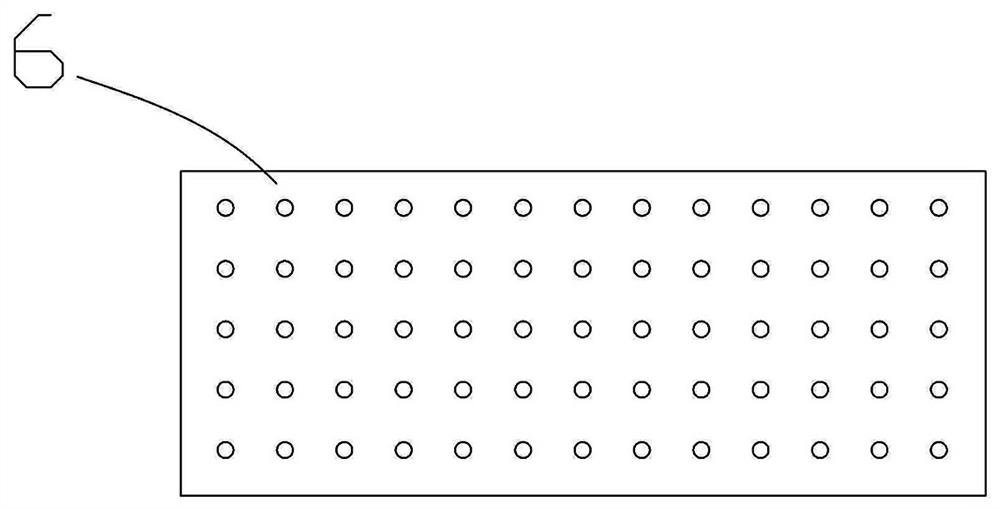

[0064] On the basis of Example 1, a low water-cement ratio phosphogypsum lightweight block or bar is prepared by using tap water to prepare ice particles, preferably round, the quality is equal to that of liquid water, and the diameter of the ice particles is 1.0 cm. According to the optimal water-cement ratio, that is, the ratio of the mass of water to the mass of dry phosphogypsum powder, quickly mix the ice particles and phosphogypsum powder evenly, and then according to the predetermined dry density, in this example, it is 0.7~1.0 g / cm 3 1. Pour the mixture of accurately measured ice particles and phosphogypsum powder into the mold, and use the press 7 to compact it to a predetermined volume; after the ice melts, the blocks or bars are demoulded after initial setting. Such as Figure 8 In the above, the phosphogypsum filled with ice particles can retain the cavity, and the hollow rate of the block is calculated by controlling the number of ice particles.

[0065] Use 0.5%...

Embodiment 3

[0078] 1. Add 50kg of tap water, add 250g of quick-setting agent, dissolve and stir evenly, pour it into a 1.5cm-sized silicone mold, and put it in the freezing area.

[0079] 2. After the ice pellets are frozen and formed, the machine is demoulded, weigh 50kg of ice pellets and 150kg of phosphogypsum according to the water-cement ratio of 33:100, pour them into the mixing chamber at the same time, and roll and stir for 15-20 seconds.

[0080] 3. After mixing evenly, feed into multiple molds. The internal length, width and height of each mold are 600mm×500mm×200mm.

[0081] 4. The preset dry density of block 9 is 0.7g / cm 3 , use pressure equipment to compact the mixture in the block mold to the predetermined volume, which is 60000cm 3 , completed within 20~30 seconds.

[0082] 5. Remove the mold loaded with blocks as a whole, and put it in the waiting area for 20-25 minutes, waiting for the ice particles to fully melt and the final setting of phosphogypsum to be basically co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com