Explosion-proof pressure-relief fire extinguishing device for battery anti-short-circuit performance test and use method thereof

A fire-extinguishing device and anti-short-circuit technology, applied in the direction of measuring device, measuring device casing, circuit, etc., can solve the problem of destroying the test equipment and exhaust system of the test site, detecting that the explosion-proof device cannot meet the safety requirements of the new battery test, explosion-proof device explosion and other problems, to ensure safety, protect personal safety and the surrounding environment, and prevent combustion and explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0038] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

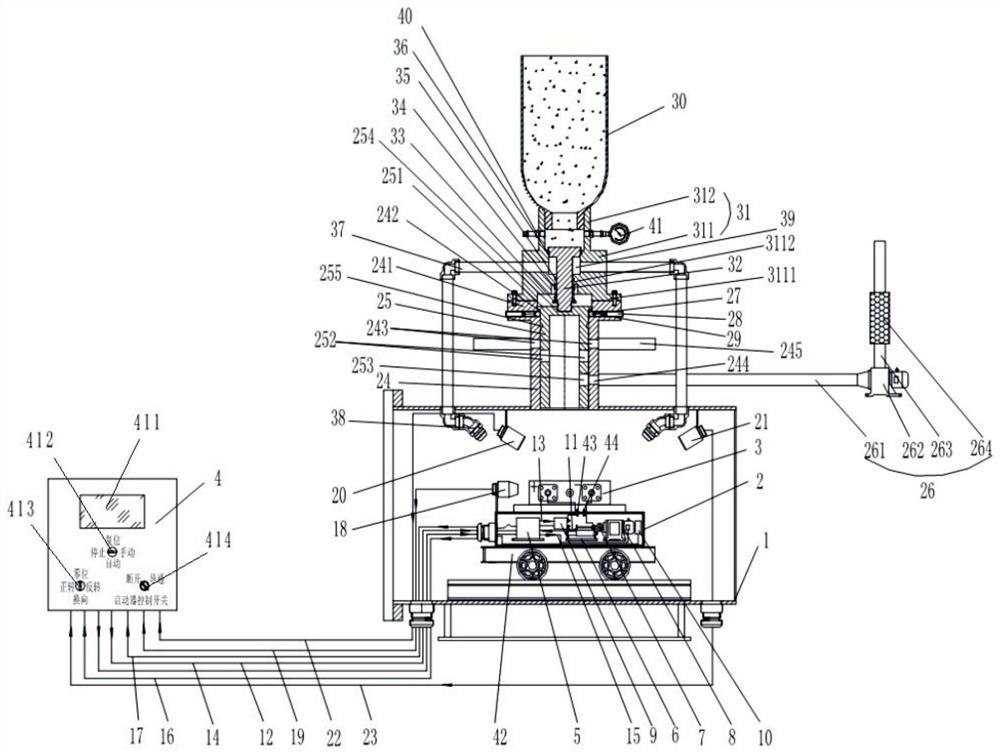

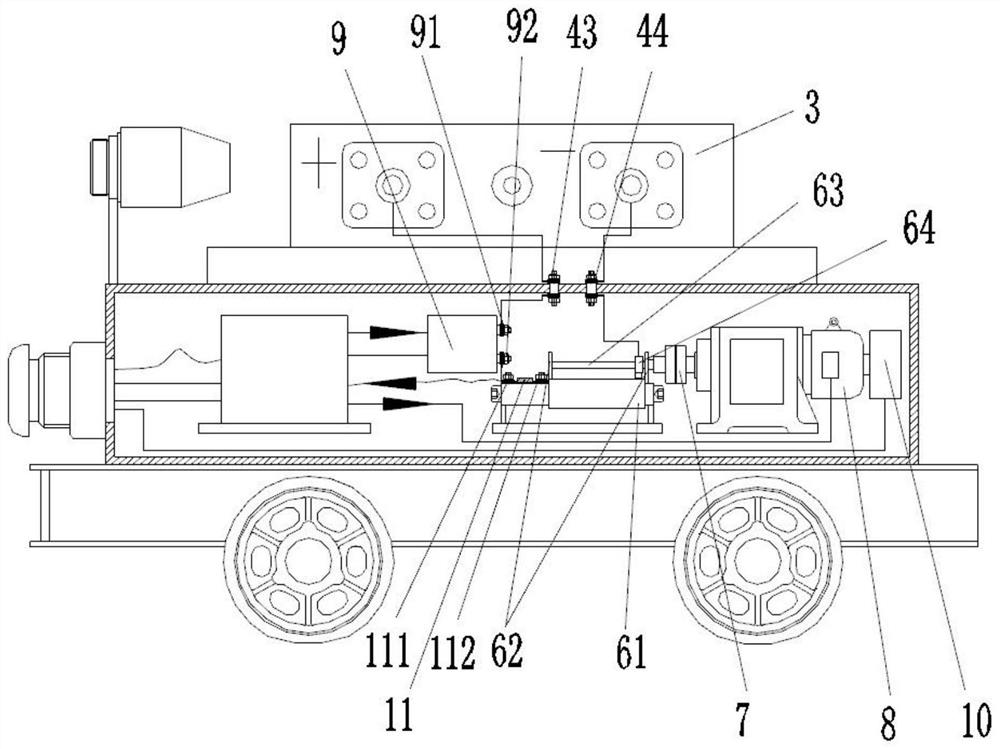

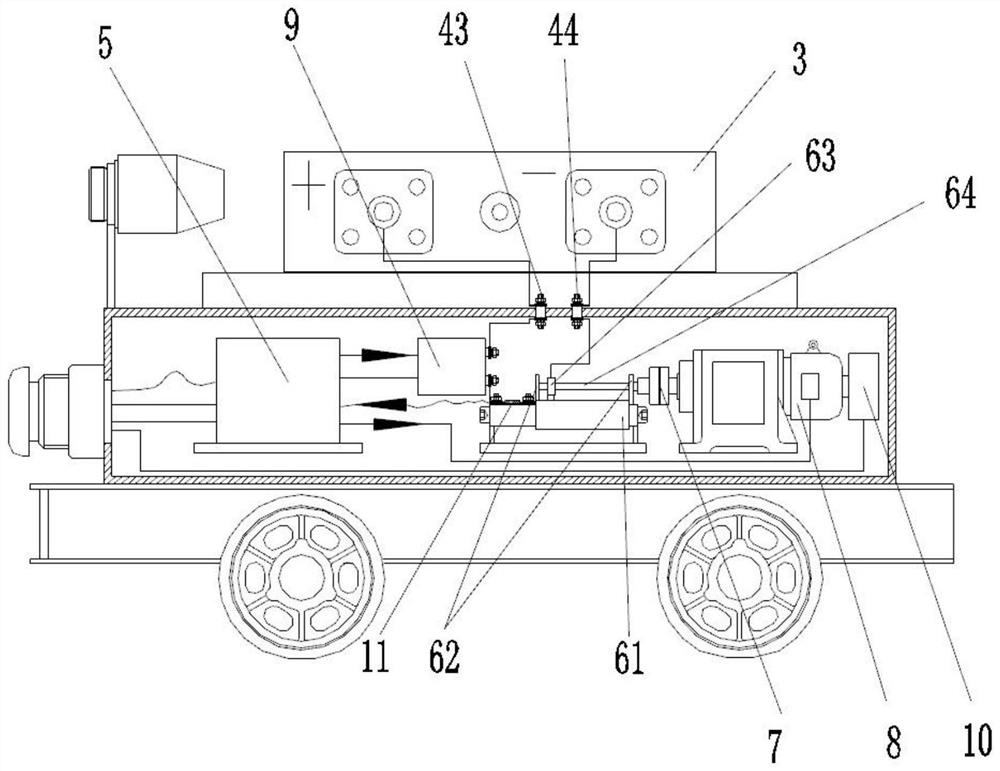

[0039] See Figure 1 - Figure 7 Battery anti-short-circuit performance test, compartment, explosion-proof leakage fire extinguishing device, including the blasting box 1, the explosion-proof case 2, battery 3, battery anti-short circuit testing mechanism, controller 4, pressure relief fire extinguishing mechanism; within the interrupt box 1 The explosion-proof case 2 is provided, and the explosion-proof case 2 is placed on the track vehicle assembly 42, and the rail vehicle assem...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap