Waste acid treatment device for dry acetylene process

A technology of waste acid treatment and dry acetylene, applied in natural water treatment, degassed water/sewage treatment, water/sludge/sewage treatment, etc. The effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

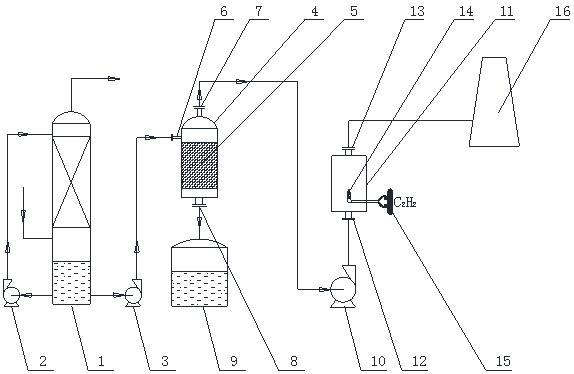

[0019] The embodiment of the present invention discloses a dry acetylene process waste acid treatment device, such as figure 1 As shown, it includes pickling tower 1, one side of pickling tower 1 is provided with acid circulation pump 2, the inlet of acid circulation pump 2 is connected with the acid outlet at the bottom of pickling tower 1, and the outlet of acid circulation pump 2 is connected with pickling tower 1 The acid inlet above the top packing layer is connected, and the pickling tower 1 is a tower tank integrated packing tower, the gas phase enters low and exits high, and the gas phase inlet is located below the packing layer and above the highest liquid level of the liquid phase.

[0020] A waste acid pump 3 is connected to the acid outlet at the bottom of the pickling tower 1, and the outlet of the waste acid pump 3 is connected to the degassing tower 4 through the acid inlet pipe. Inside the degassing tower 4 , the degassing tower 4 is provided with a degassing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com