Intelligent all-electric workover rig

A workover rig, all-electric technology, applied to drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of reducing labor intensity, increasing speed, and facilitating intelligent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

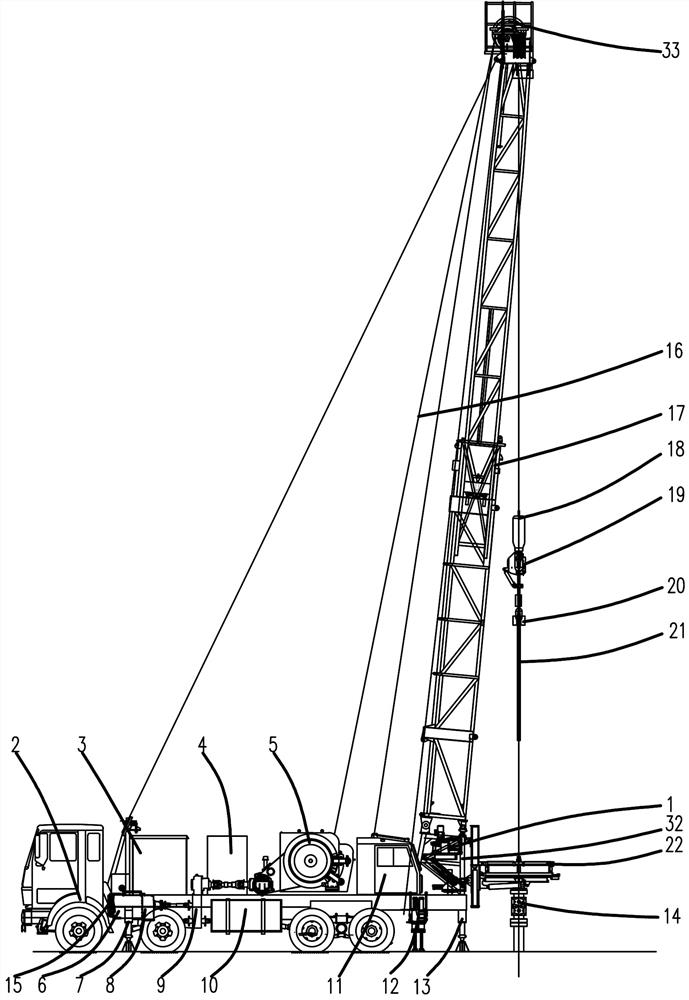

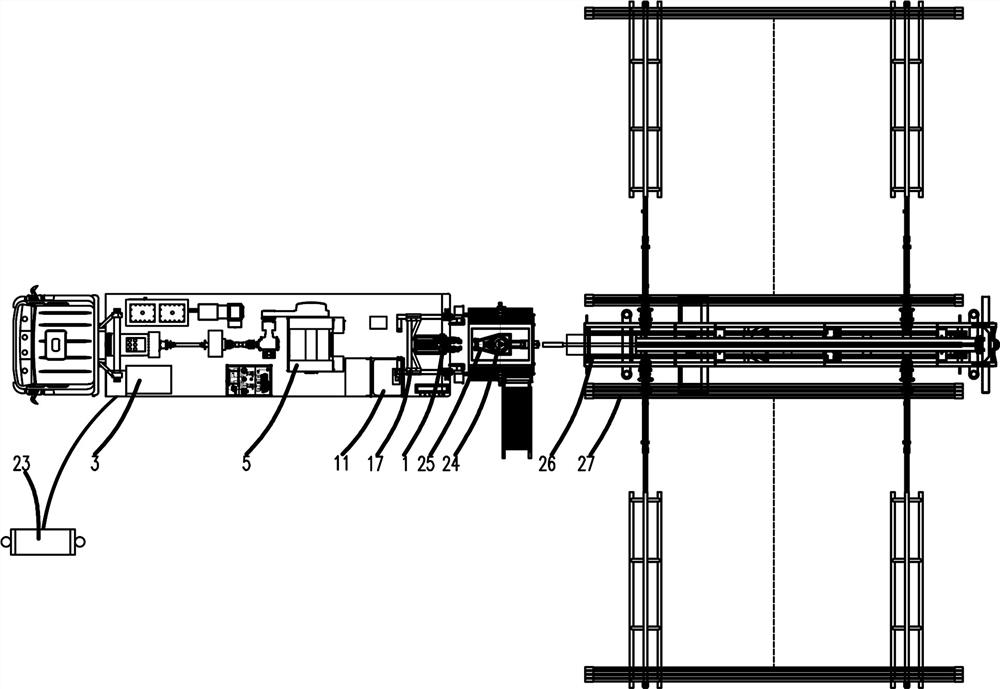

[0046] Such as figure 1 , 2 Among them, an intelligent full power mechanism, including the electric drive body 2, and is provided with a power management system 3 on the electric drive body 2. The power supply management system 3 is electrically connected to the drive motor 6, and the drive motor 6 is connected to the hydraulic station 4. There is also a winch assembly 5. There are two driving methods of winch, including driving motor 6 direct drive and hydraulic drive, using a drive motor 6 direct drive on a small device, in large equipment, such as hydraulic clamp main clamp A well-formed machine in diameter 73 to 141 mm is hydraulically driven.

[0047] Such as figure 1 In the electric drive body 2, there is also a well grid base 32, and the top portion of the wellboil base 32 is hinged, and the tail of the electric drive body 2 is also connected to the work platform 22;

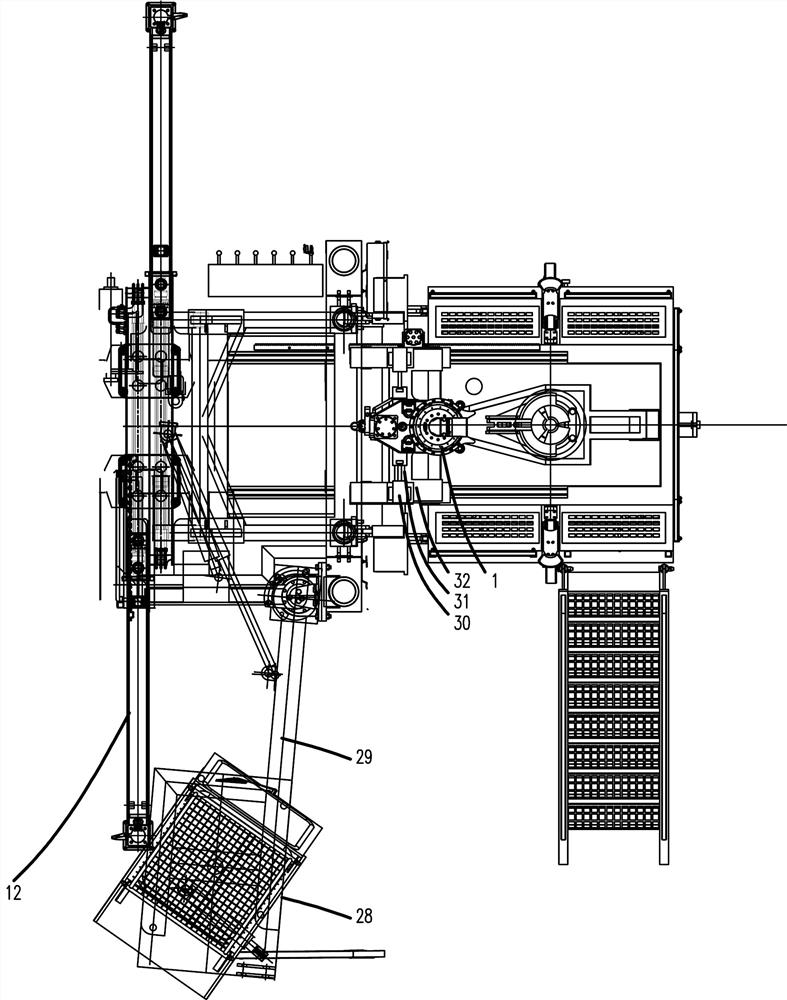

[0048] Such as image 3 , 4 In, the wellbore base 32 is provided with an intelligent hydraulic clamp 1 (sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com