Super-hydrophobic fluorocarbon chain modified titanium dioxide as well as preparation method and application thereof

A super-hydrophobic, fluorocarbon chain technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as poor super-hydrophobic effect, and achieve high product yield, simple steps, good product The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

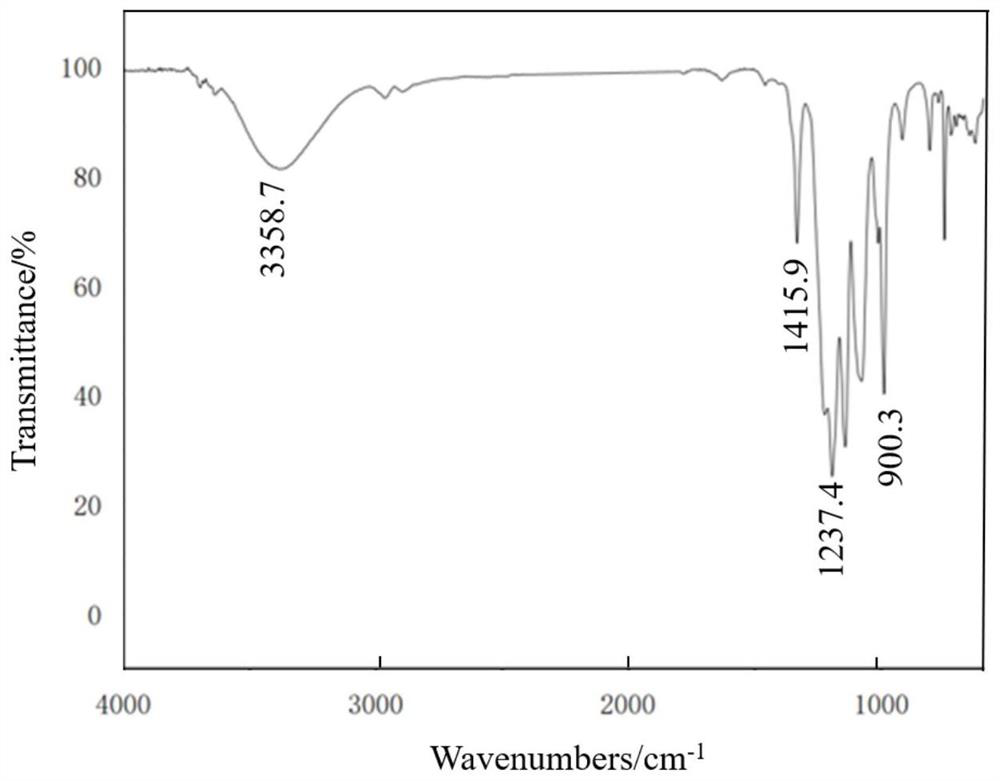

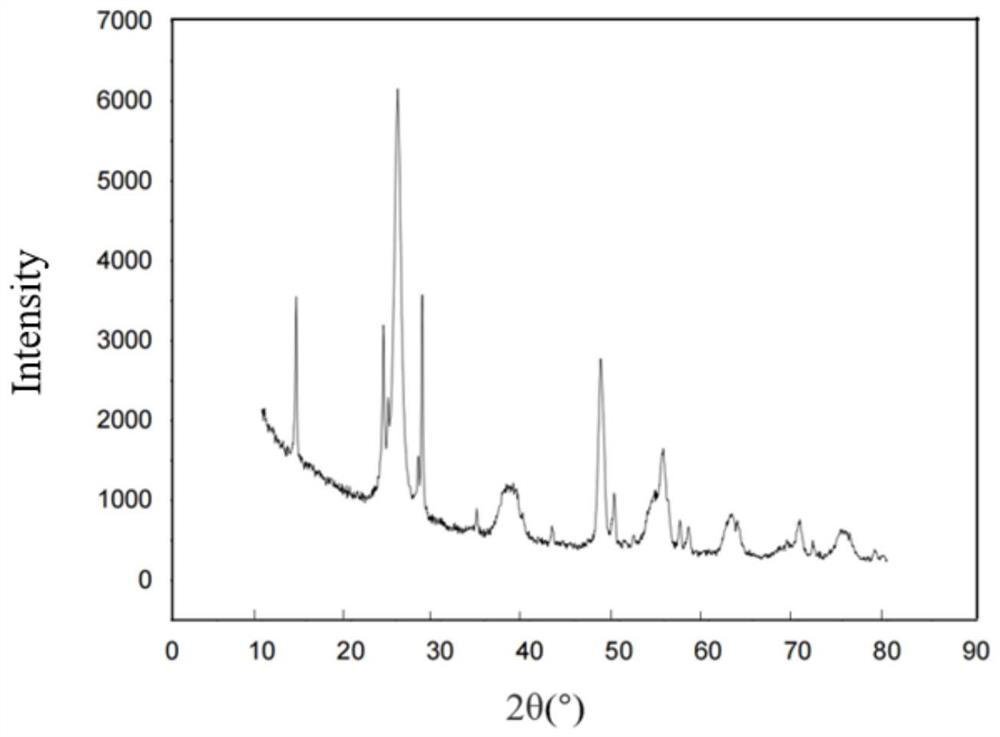

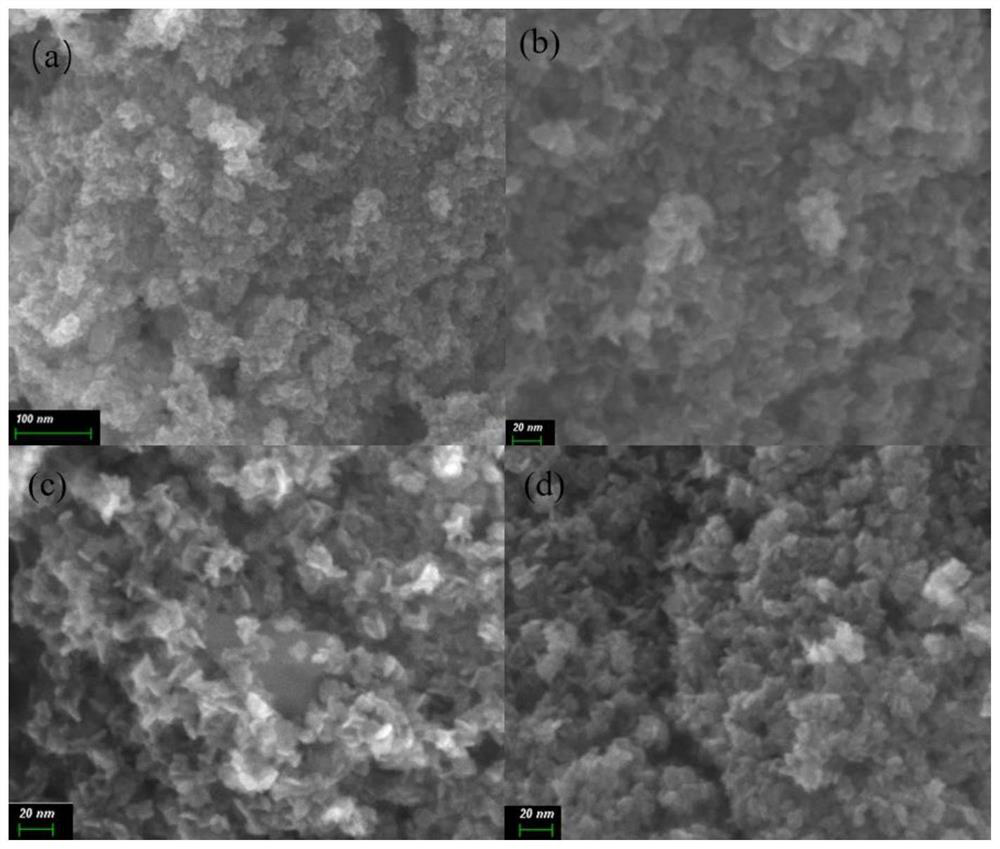

[0026] 1. Fluorocarbon chain modified TiO 2 nanoparticles

[0027] Take 10ml of titanium tetrachloride and 30ml of ice water with a graduated cylinder. At room temperature and stirring at a speed of 700r / min, add 10ml (0.09mol) of titanium tetrachloride dropwise to 30ml of ice water at a rate of 2s / drop in a beaker, and then add hexafluoroepoxide dropwise at a rate of 2s / drop. Propane dimer 28.5g (0.09mol), after stirring at 700r / min for 60min, the reaction solution was transferred to a stainless steel reactor and heated to 100°C for 3h reaction. 2-tetrafluoroethyl-2,2,2-trifluoroethyl ether) and deionized water were washed 5 times to remove chloride ions on the surface, and the chloride ion content detector (model TDCL-225, manufacturer Beijing Tiandi Shouhe Technology) Development Co., Ltd.) after measuring the concentration of chloride ions in the washing solution to be 15ppm, centrifuge with a centrifuge at a speed of 7000r / min, dry the resulting solid at 120°C for 18h, ...

Embodiment 2

[0040] Take 3ml of tetrabutyl titanate and 3ml of ice water with a graduated cylinder. Under the condition of stirring at room temperature and rotating speed of 500r / min, add 3ml (0.009mol) tetrabutyl titanate dropwise to 10ml ice water at a speed of 3s / drop in a beaker, and then add difluoroacetic acid dropwise at a speed of 3s / drop 3.5g (0.036mol), stirred at 500r / min for 60min, the reaction solution was transferred to a stainless steel reactor and heated to 150°C for 2h, after taking it out, use hydrofluoroether HFE-6512 (1H, 1H, 5H-octafluoropentyl -1,1,2,2-tetrafluoroethyl ether) and deionized water for 5 times to remove impurities on the surface, the chloride ion concentration measured by a chloride ion content detector is 16ppm, and the centrifuge is used at a speed of 5000r / min Centrifuge, dry the resulting solid at 80°C for 24 hours, and grind it with an agate mortar for 30 minutes to obtain 1.4 g of white fluorocarbon chain-modified TiO 2 Nano particle powder, the m...

Embodiment 3

[0043] Take 10ml of titanium tetrachloride and 20ml of ice water with a graduated cylinder. At room temperature and stirring at a speed of 600r / min, add 10ml (0.09mol) of titanium tetrachloride dropwise to 25ml of ice water at a rate of 4 s / drop in a beaker, and then add 2,2-dichloride at a rate of 4 s / drop. Fluoropropionic acid 17.3g (0.18mol), after stirring at 600r / min for 60min, the reaction solution was transferred to a stainless steel reactor and heated to 80°C for 8h, and after taking it out, it was washed 6 times with hydrofluoroether HFE-6512 and deionized water to remove Impurities on the surface, after the chlorine ion concentration is measured to be 12ppm by a chloride ion content analyzer, centrifuge at a speed of 7000r / min with a centrifuge, dry the resulting solid at 150°C for 20h, and grind it with an agate mortar for 30min to obtain 15.7g of white Fluorocarbon chain modified TiO 2 Nano particle powder, the mass yield is 96.6%.

[0044] Using the method of Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com