Mitral valve prosthesis

A heart valve and mitral valve technology, applied in the field of artificial mitral valve heart valve, can solve problems such as material fatigue, sail folds, creep, etc., and achieve the effect of reducing mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

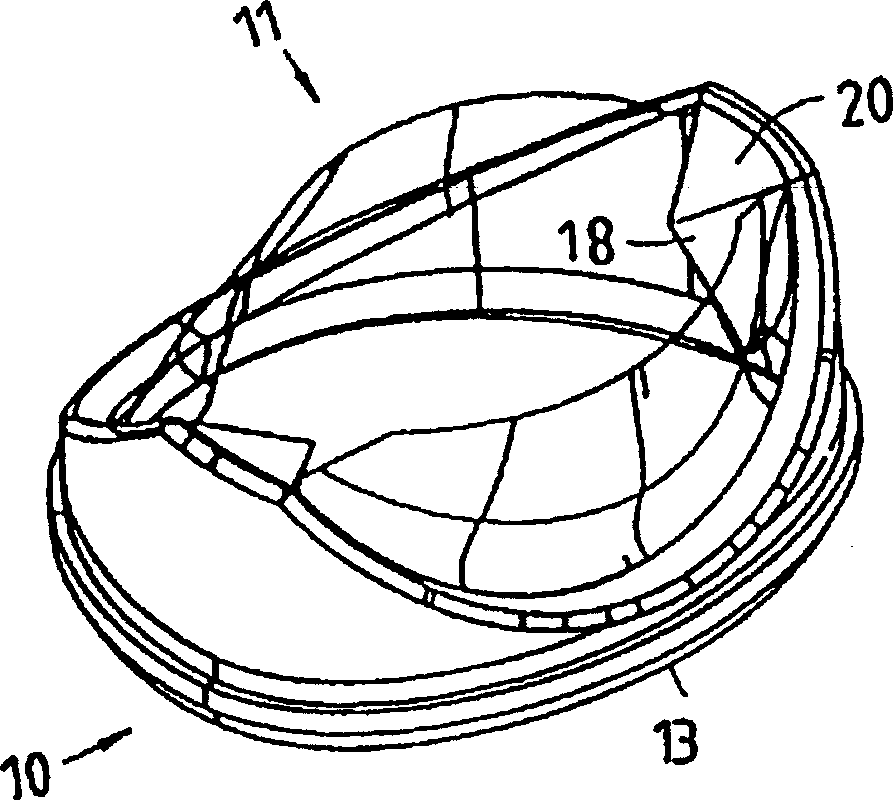

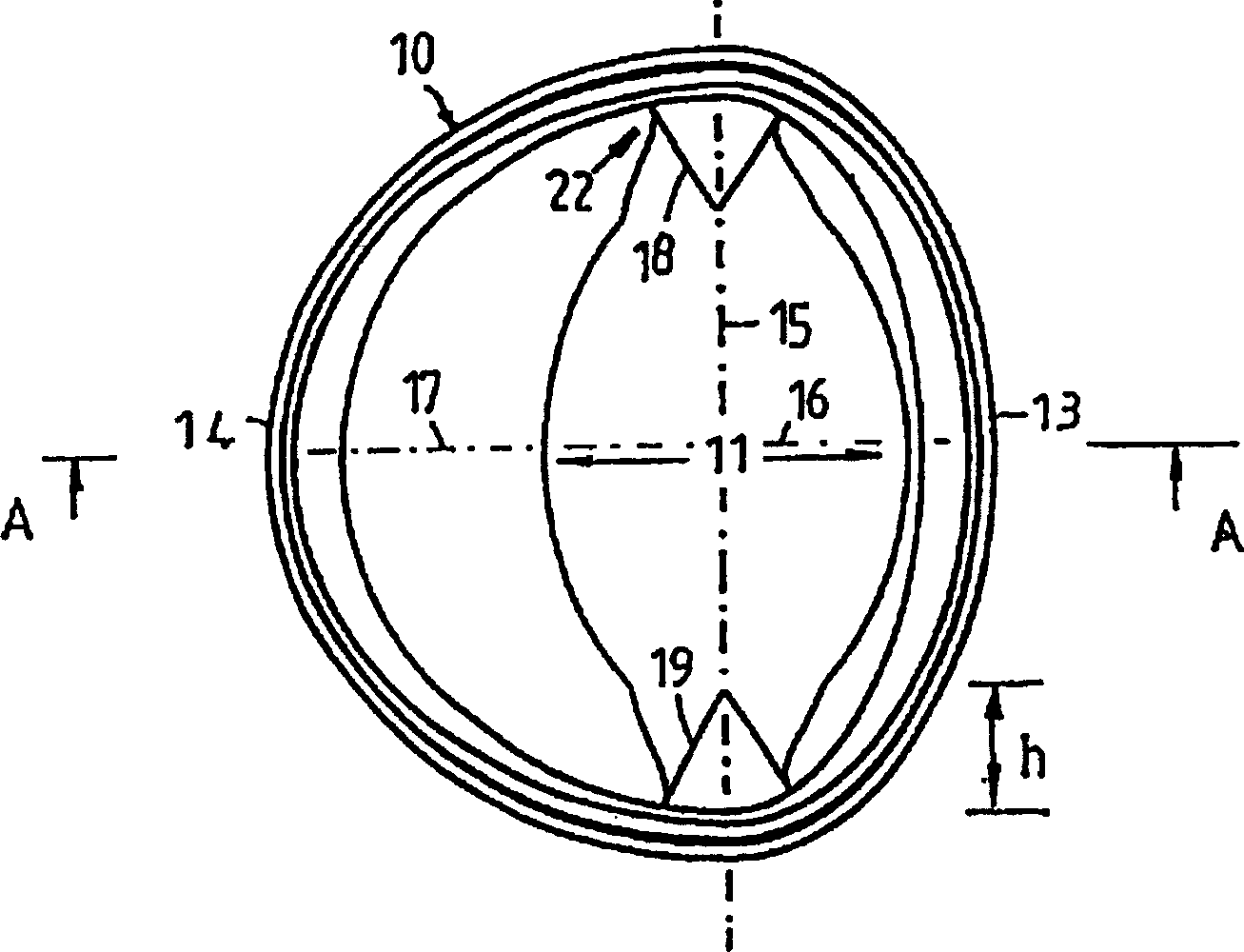

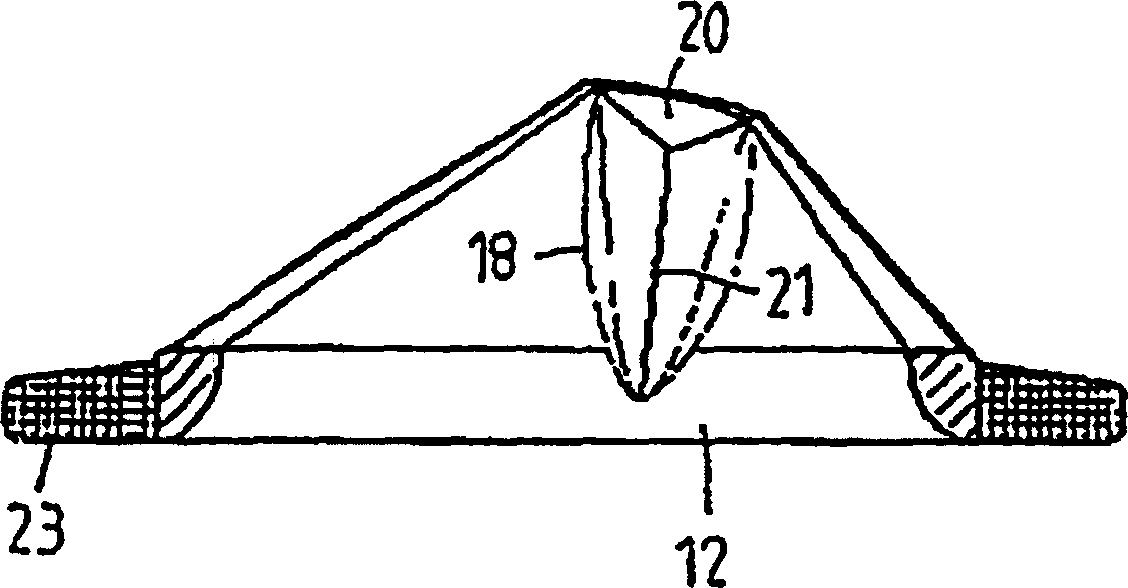

[0024] The artificial mitral heart valve consists of a support housing 10 with two sails 11 (Segel). The support shell 10 is sewn into the patient's tissue by means of a sewing ring 23 in the valve annulus. The support shell 10 is made of a thermoplastic such as nylon, for example by injection molding, into a body with low flexural elasticity, followed by an outer coating of polyurethane. The integral support housing 10 has a base ring 12 whose inner edges are rounded as far as the outer surface in a manner known from the state of the art. In order to better fix the sewing ring 23, the base ring can have a lug on the outer shell. The wall substantially perpendicular to the bottom surface of the base ring is divided into a first wall 13 with a smaller curvature and a second wall 14 with a greater curvature, which form two halves with a common longitudinal axis 15 seen in plan view towards the base. shape. Since the two transverse semi-axes 16 and 17 have different lengths, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com