Aluminum bar hot shearing machine with double-shearing function

A technology of hot shearing machine and aluminum bar, which is applied to the accessories of shearing machine, manufacturing tools, shearing device, etc. Long and splicing, ensure the measurement accuracy, and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

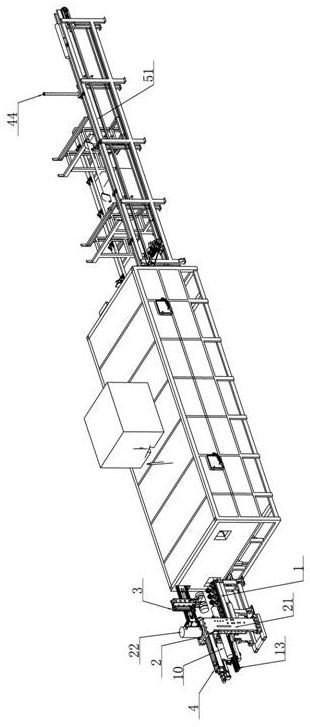

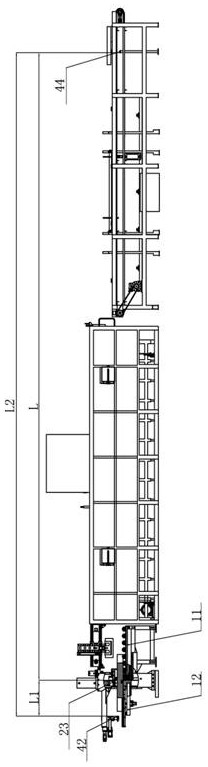

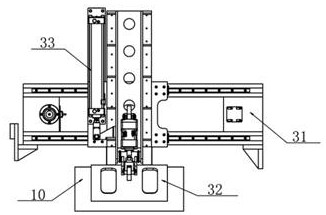

[0023] The hot aluminum rod shearing machine with double shearing function of the present invention mainly includes an aluminum rod conveying mechanism, a thermal shearing mechanism, a double shearing mechanism and a length-setting mechanism, such as Figure 1-Figure 2 As shown, compared with conventional horizontal thermal shears, vertical thermal shears are adopted in this embodiment. Wherein, hot shearing mechanism 2 comprises frame 21, the vertical blade 23 that is arranged in frame and aluminum rod clamping unit, the shear driver 22 (such as oil cylinder) that frame top is provided with, and aluminum rod clamping unit can It includes a clamping plate and a pressing oil cylinder, etc., and the pressing oil cylinder can also be arranged on the top of the frame, further saving the space occupied by the whole equipment. In addition, a return driver (such as an oil cylinder) for driving the aluminum rod back to the aluminum rod heating furnace 5 and an ejection driver (such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com