BARC resin for narrow-distribution 193nm deep ultraviolet photoresist and preparation method of BARC resin

A technology of deep ultraviolet light and narrow distribution, applied in the field of polymers, can solve the problem of molecular weight not having a narrow distribution, achieve stable light absorption performance, consistent external stress response, and reduce light reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

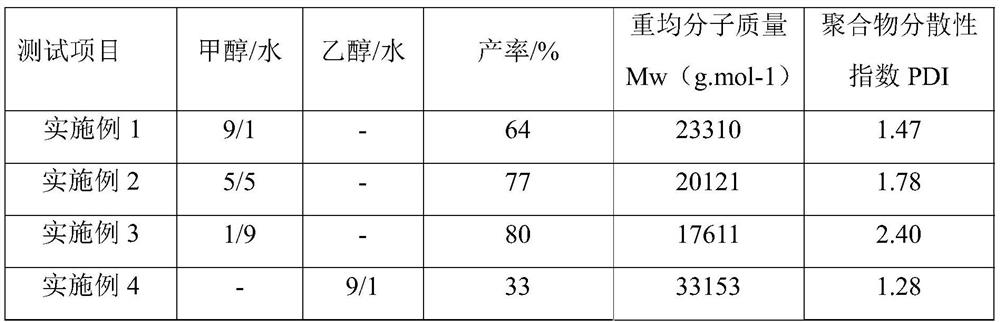

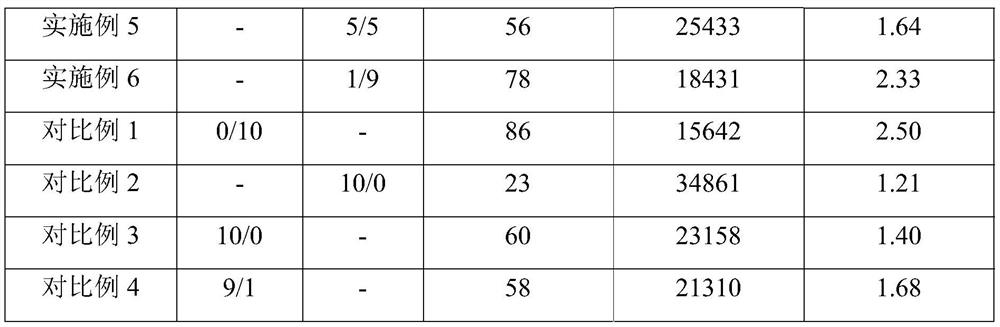

Examples

Embodiment 1

[0026] A kind of preparation method of BARC resin for 193nm deep ultraviolet photoresist of narrow distribution, comprises the following steps:

[0027] Mass ratio: the ratio of p-hydroxystyrene, styrene, hydroxypropyl methacrylate, and tetrahydrofuran solvent is 1:1:1:12, and the ratio of carboxylated fullerene to initiator is 13:0.06.

[0028] S1. Put p-hydroxystyrene, styrene and hydroxypropyl methacrylate in a four-necked flask containing tetrahydrofuran solvent, and stir until the monomers are evenly mixed;

[0029] S2. After the monomer is dissolved, add the carboxylated fullerene and the initiator azobisisobutyronitrile, and stir until dissolved;

[0030] S3. Place the four-neck flask with the reaction solution in an oil bath equipped with a magnetic stirrer. After installing the condenser tube and the nitrogen port, turn on the condensed water, feed in nitrogen, turn on the stirring and raise the temperature to The boiling point of the solvent is 65°C. After the boili...

Embodiment 2

[0034] A kind of preparation method of BARC resin for 193nm deep ultraviolet photoresist of narrow distribution, comprises the following steps:

[0035] Mass ratio: the ratio of p-hydroxystyrene, styrene, hydroxypropyl methacrylate, tetrahydrofuran solvent is 2:1-10:2:20, and the ratio of carboxylated fullerene to initiator is 20:0.1 .

[0036] S1. Put p-hydroxystyrene, styrene and hydroxypropyl methacrylate in a four-necked flask containing tetrahydrofuran solvent, and stir until the monomers are evenly mixed;

[0037] S2. After the monomer is dissolved, add the carboxylated fullerene and the initiator azobisisovaleronitrile, and stir until dissolved;

[0038] S3. Place the four-neck flask with the reaction solution in an oil bath equipped with a magnetic stirrer. After installing the condenser tube and the nitrogen port, turn on the condensed water, feed in nitrogen, turn on the stirring and raise the temperature to The boiling point temperature of the solvent is 65.2°C. A...

Embodiment 3

[0042] A kind of preparation method of BARC resin for 193nm deep ultraviolet photoresist of narrow distribution, comprises the following steps:

[0043] Mass ratio: the ratio of p-hydroxystyrene, styrene, hydroxypropyl methacrylate, tetrahydrofuran solvent is 3:3:4:30, and the ratio of carboxylated fullerene to initiator is 30:0.2.

[0044] S1. Put p-hydroxystyrene, styrene and hydroxypropyl methacrylate in a four-necked flask containing tetrahydrofuran solvent, and stir until the monomers are evenly mixed;

[0045] S2. After the monomer is dissolved, add the carboxylated fullerene of the hollow spherical network substance and the initiator azobisisoheptanonitrile, and stir until dissolved;

[0046] S3. Place the four-neck flask with the reaction solution in an oil bath equipped with a magnetic stirrer. After installing the condenser tube and the nitrogen port, turn on the condensed water, feed in nitrogen, turn on the stirring and raise the temperature to The boiling point t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com