High-temperature expansion joint with anti-vibration and heat-insulation structure

A high-temperature expansion and anti-vibration technology, which is applied in the field of expansion joints, can solve problems such as heat insulation material falling off, safety hazards, and expansion joint failure, and achieve the effects of preventing falling off, prolonging life, and reducing vibration deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

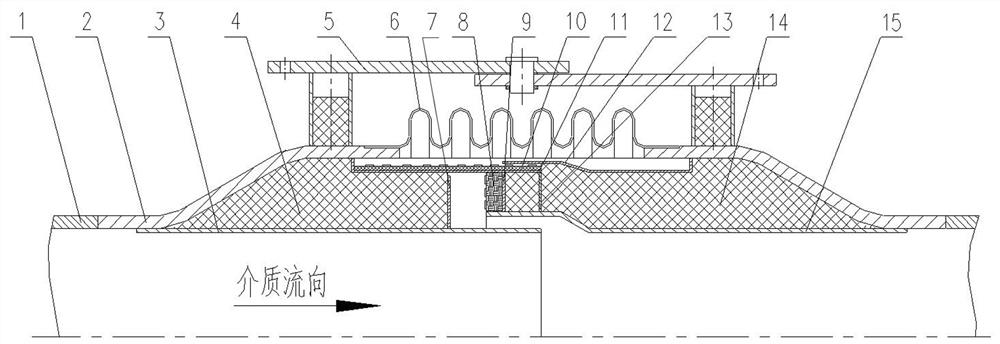

[0021] The present invention is described with reference to the drawings and specific embodiments. However, the present invention is not limited to these embodiments, but can also be applied to other pipelines with the same working conditions.

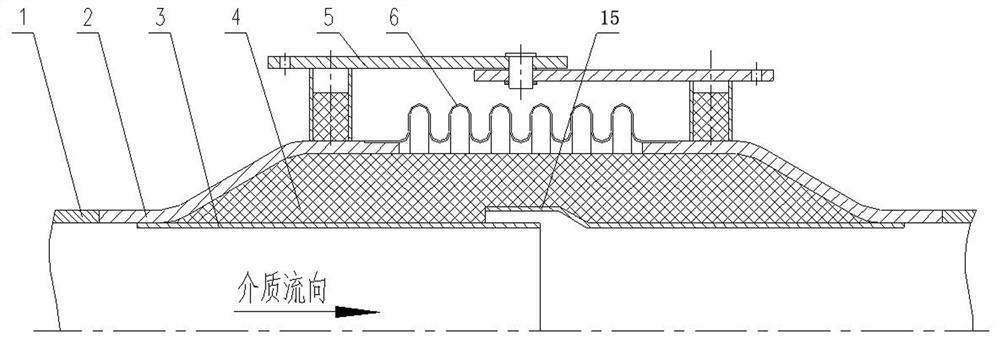

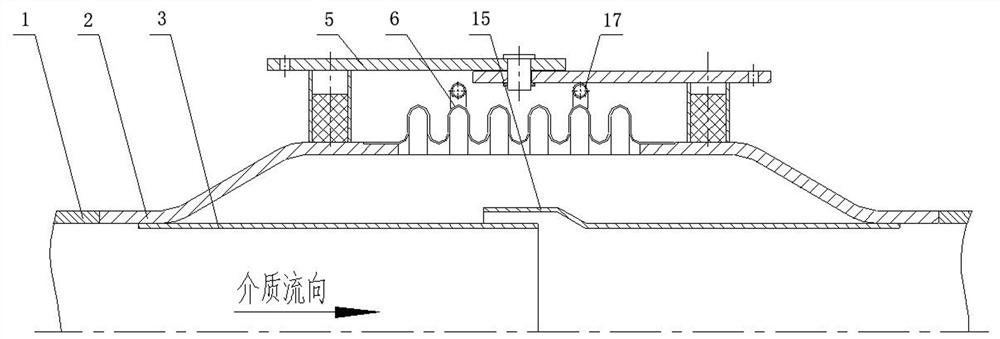

[0022] Such as image 3 As shown, a high-temperature expansion joint with a vibration-proof and heat-insulating structure includes a bellows 6, end pipes 2 connected to both sides of the bellows 6, an inlet guide tube 3 and an outlet guide tube 15, and the outlet guide tube 15 The tail end of the inlet is lapped on the inlet guide tube 3, and there is a gap between the lapped parts, such as figure 1 As shown, the bellows 6, the inlet guide tube 3, the outlet guide tube 15 and the end pipe 2 enclose the heat insulation layer filling space for filling the heat insulation layer, and anti-vibration and heat insulation are provided in the heat insulation layer filling space. Mechanism, anti-vibration heat insulation mechanism includes inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com