PB composite pipe as well as preparation method and application thereof

A composite pipe and formula technology, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of troublesome handling and installation process, short service life of metal pipes, easy to corrode and rust, etc. The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

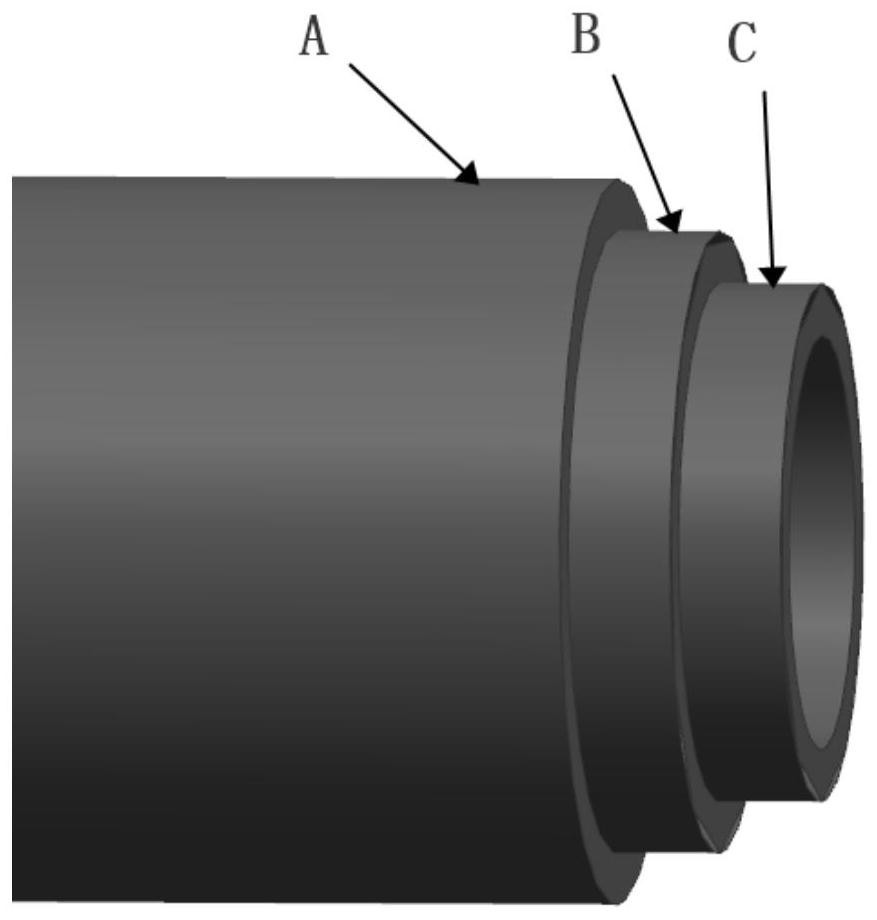

[0034] Embodiment 1 provides a PB composite pipe, which is a three-layer composite structure. From the outside to the inside, it is an anti-corrosion outer layer A, an insulation layer B and a working inner layer C. The wall thickness of the anti-corrosion outer layer is 0.5mm, and the insulation layer The wall thickness of the wall is 8mm, and the wall thickness of the working inner layer is 3.1mm. The anti-corrosion outer layer and the insulation layer are bonded by a film coating process, and the insulation layer and the working inner layer are bonded by an adhesive.

[0035] Specifically, the anti-corrosion outer layer is made of high-density polyethylene material. The high-density polyethylene material is composed of the following components by weight: 95 parts of HDPE (HDPE 6100M), 0.2 part of antioxidant 1010, 0.1 part of antioxidant 168, 0.2 part of ultraviolet absorber 770, 0.1 part of ultraviolet absorber 944, 0.3 parts of PE wax (dispersant), 5 parts of MBS (anti-im...

Embodiment 2

[0044] Embodiment 2 provides a PB composite pipe, which is a three-layer composite structure. From the outside to the inside, it is an anti-corrosion outer layer A, an insulation layer B and a working inner layer C. The wall thickness of the anti-corrosion outer layer is 0.8mm, and the insulation layer The thickness of the wall is 10mm, the wall thickness of the working inner layer is 2.8mm, the anti-corrosion outer layer and the insulation layer are bonded by film coating process, and the insulation layer and the working inner layer are bonded by adhesive. The thickness is the same as in Example 1.

[0045] Specifically, the anti-corrosion outer layer is made of high-density polyethylene material. The high-density polyethylene material is composed of the following components by weight: 90 parts of HDPE (HDPE 6100M), 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 0.1 part of ultraviolet absorber 770, 0.1 part of ultraviolet absorber 944, 0.2 parts of dispersant, 3...

Embodiment 3

[0050] Embodiment 3 provides a PB composite pipe, which is a three-layer composite structure. From the outside to the inside, it is an anti-corrosion outer layer A, an insulation layer B and a working inner layer C. The wall thickness of the anti-corrosion outer layer is 0.6mm, and the insulation layer The thickness of the wall is 8mm, the wall thickness of the working inner layer is 3mm, the anti-corrosion outer layer and the insulation layer are bonded by a film coating process, the insulation layer and the working inner layer are bonded by an adhesive, and the thickness of the adhesive is Same as Example 1.

[0051] Specifically, the anti-corrosion outer layer is made of high-density polyethylene material. The high-density polyethylene material is composed of the following components by weight: 100 parts of HDPE (HDPE 6100M), 0.3 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.3 part of ultraviolet absorber 770, 0.2 part of ultraviolet absorber 944, 0.5 parts of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com