Phenol-ammonia wastewater treatment device and process for degassing and grading treatment of light oil and heavy oil

A technology for wastewater treatment and grading treatment, which is applied in degassed water/sewage treatment, centrifugal separation water/sewage treatment, water treatment parameter control, etc. To achieve the effect of shortening processing time and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

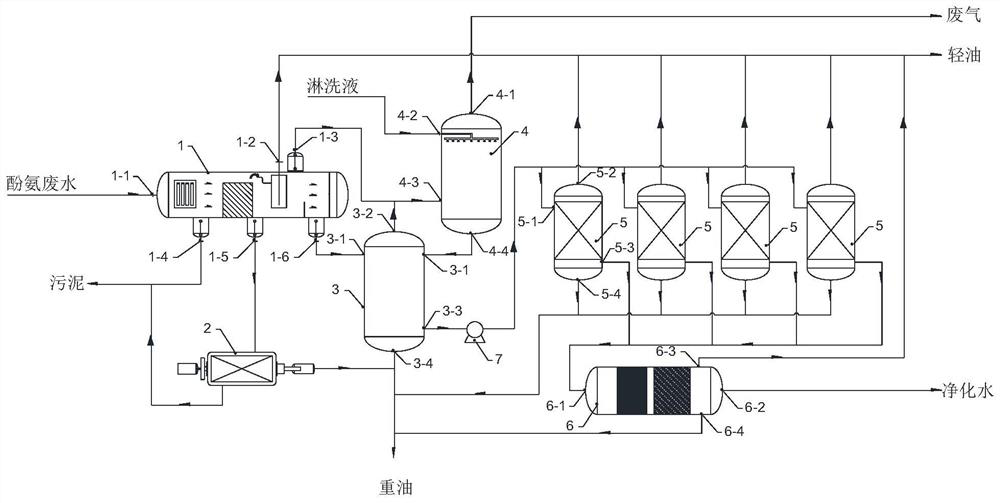

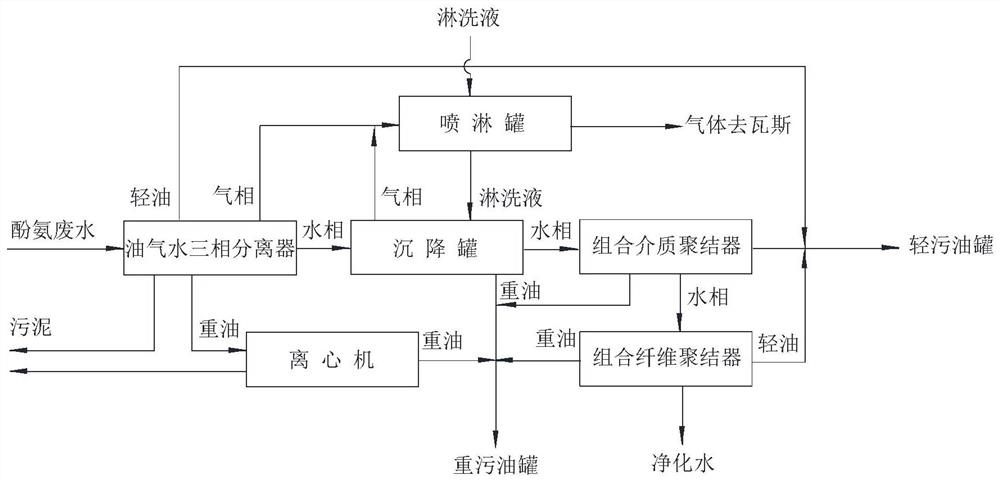

[0040] The invention provides a kind of phenolic ammonia wastewater treatment device for degassing and classification treatment of light and heavy oil, such as figure 1 and figure 2 As shown, the phenol ammonia wastewater treatment plant includes an oil-gas-water three-phase separator 1, a centrifuge 2, a settling tank 3, a spray tank 4, a combined medium coalescer 5 and a combined fiber coalescer 6, wherein:

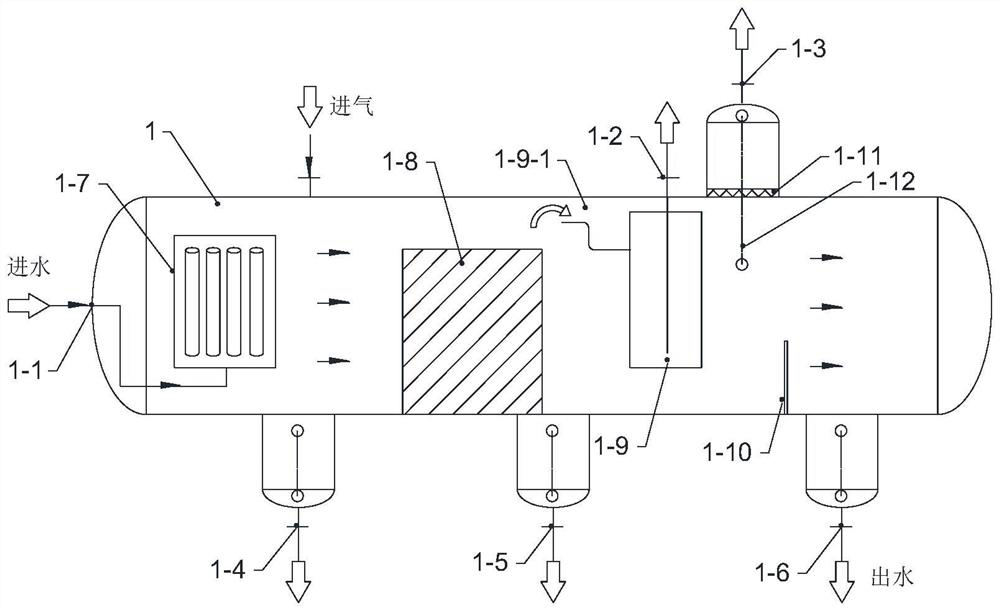

[0041] The oil-gas-water three-phase separator 1 is a horizontal separator for pre-separation of the oil phase, solid phase, gas phase and water phase in the phenol ammonia wastewater, and one end of the oil-gas-water three-phase separator 1 is provided with a phenol Ammonia wastewater inlet 1-1, light oil phase outlet 1-2 and gas phase outlet 1-3 are arranged on the top, solid phase outlet 1-4, heavy oil phase outlet 1-5 and water phase outlet 1-6 are arranged in sequence at the bottom; The inlet of the centrifuge 2 is connected with the heavy oil phase outlet 1-5 of...

Embodiment 2

[0079]Aiming at the problems of long process flow, long processing time, and substandard outlet water quality in the treatment of phenol ammonia wastewater in an existing chemical plant. The phenol ammonia waste water flow rate of described chemical plant is 300m 3 / h, the composition is complex, wherein the total phenol content is 6000mg / L, the ammonia nitrogen content is greater than 8000mg / L, and the oil content is 8500mg / L. The oil phase composition is complex, including light oil and heavy oil, and the suspended solid content is greater than 1000mg / L. The pH is 9 and contains a lot of dissolved gases.

[0080] The phenolic ammonia wastewater treatment process of degassing and light and heavy oil graded advanced treatment described in Example 1 is used to carry out deep and efficient treatment of the described phenolic ammonia wastewater, so that the oil content in the purified water after treatment is less than 300mg / L, and the suspended solids content is less than 100mg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com