Wire production defect detection method based on image processing

A defect detection and image processing technology, applied in the field of image processing, can solve problems such as the influence of wire usage, image over-balance, under-balance, etc., to achieve the effect of improving accuracy, contrast, and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1

[0025] The main application scenario of the present invention is: wire in the production process, the plastic shell may appear particles, bulges or scratches and other defects, the defective wire description production is unqualified, so it is necessary to combine computer and image processing technology to obtain a surface image of the wire, the production defects of the wire are detected.

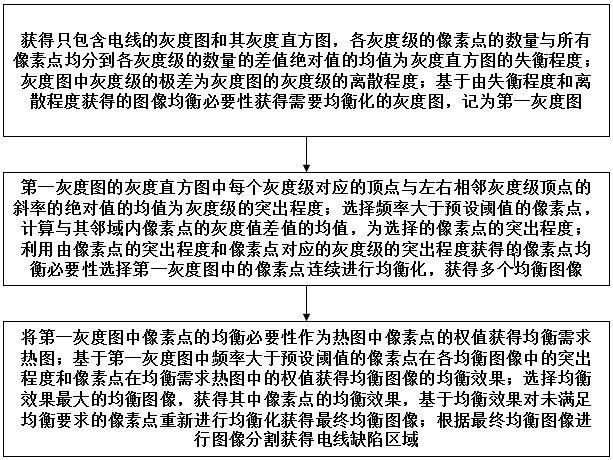

[0026] See Figure 1 , which illustrates a flowchart of a defect detection method based on image processing wire production provided in one embodiment of the present invention, the method comprising the following steps:

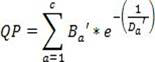

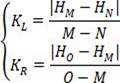

[0027] Step 1: Obtain a grayscale plot containing only wires and its grayscale histogram, the average of the absolute value of the difference between the number of pixels at each gray level and the number of all pixels divided into each gray level is the degree of imbalance of the grayscale histogram; the difference between the grayscale level in the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap