Preparation system and method of high-toughness medical coating non-woven fabric

A preparation system and non-woven fabric technology, applied in the cutting of textile materials, textile/flexible product manufacturing, non-woven fabrics, etc., can solve the problems that the fiber web cannot be completely separated, affects the reinforcement of non-woven fabrics, and the fiber web is broken , to achieve the effect of improving the practical effect, avoiding incomplete separation, and increasing the solidification distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

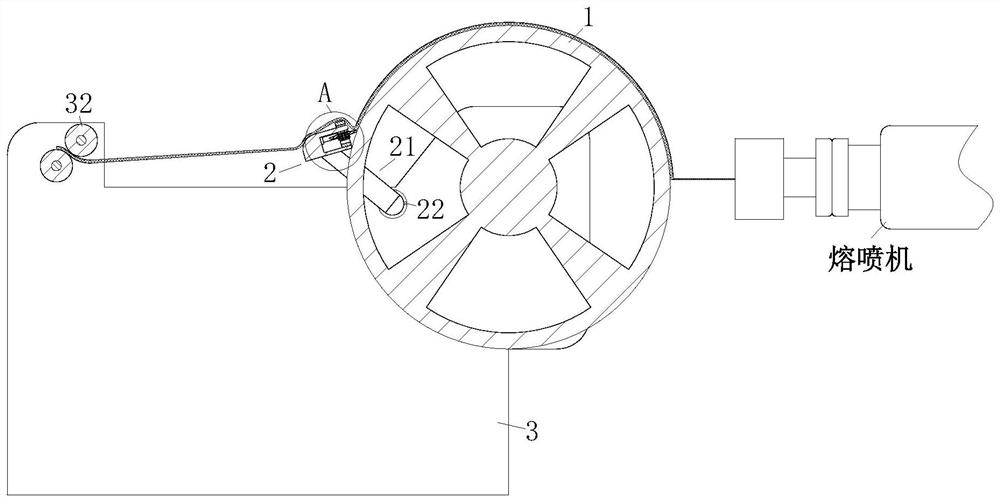

[0038] As an embodiment of the present invention, the support rod 21 includes a No. 1 straight rod 23 and a No. 2 straight rod 24; the No. 1 straight rod 23 and the mounting frame 3 are rotatably connected by a torsion spring 22. One end of the rod 23 away from the roller 1 is provided with a No. 1 groove 231 ; a No. 2 straight rod 24 is slidably connected in the No. 1 groove 231 ; The No. 1 spring 25 is used to fix the connection; when working, when the roller 1 with a larger diameter is used, the staff pulls the separating plate 4 away from the roller 1, so that the separating plate 4 drives the No. 2 straight rod 24 to move synchronously, so that the two The No. 1 straight rod 24 stretches the No. 1 spring 25 and moves away from the groove bottom of No. 1 groove 231. At this time, the staff can replace the roller 1. When the roller 1 is replaced, the staff releases the separation plate 4, and a Under the action of the restoring force, the No. 1 spring 25 can pull the No. 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com