Application of brick-concrete recycled fine aggregate in lightweight aggregate concrete and mixing method

A technology of lightweight aggregate concrete and recycled fine aggregate, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effect of improving functionality, high water absorption rate, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

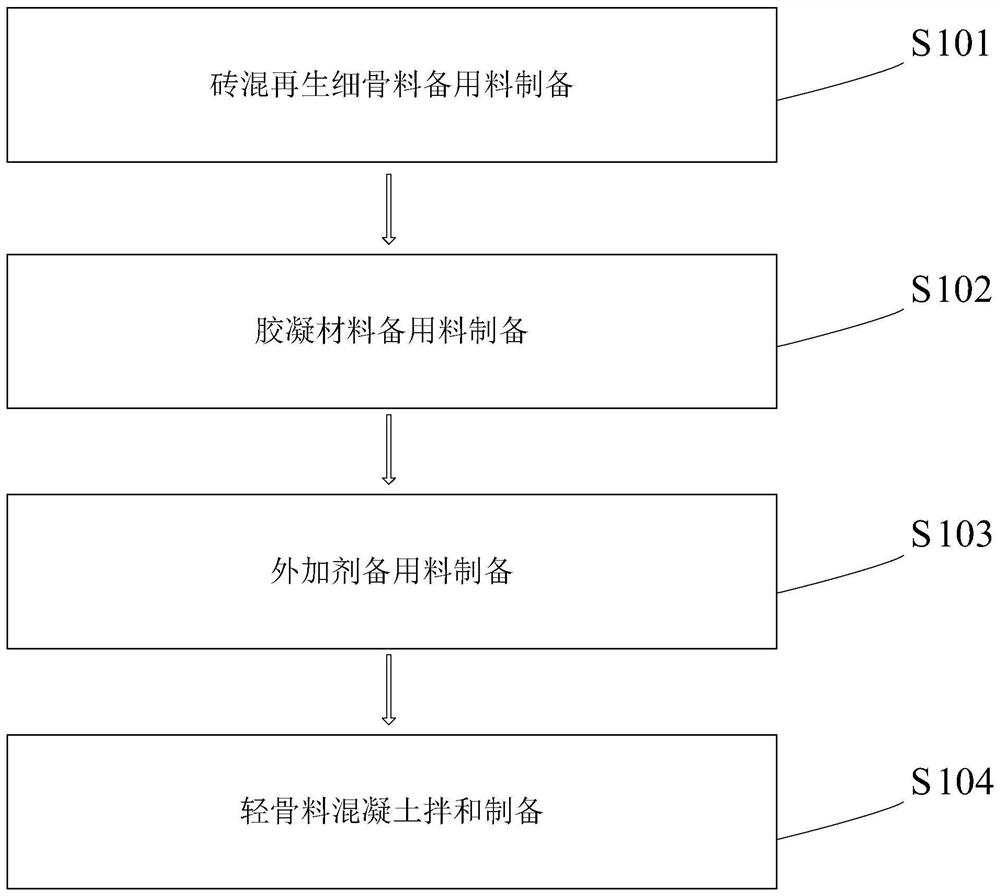

Method used

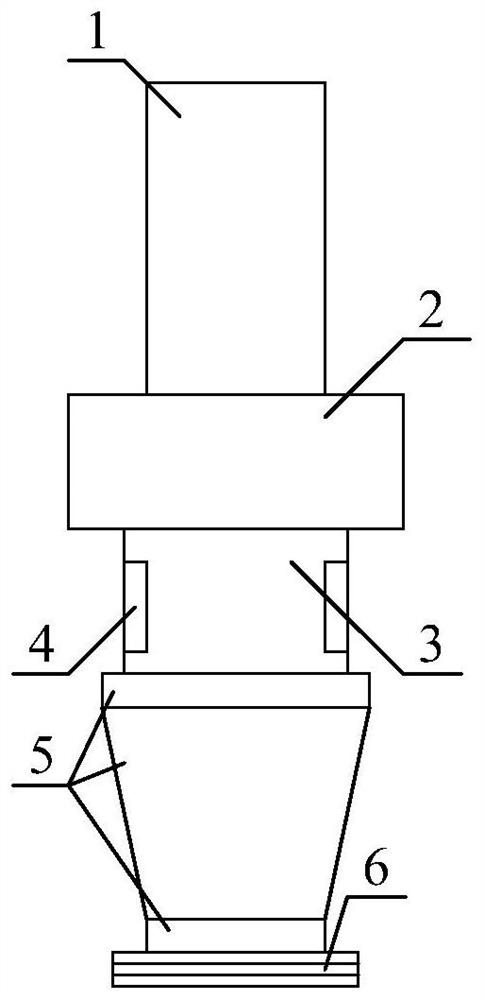

Image

Examples

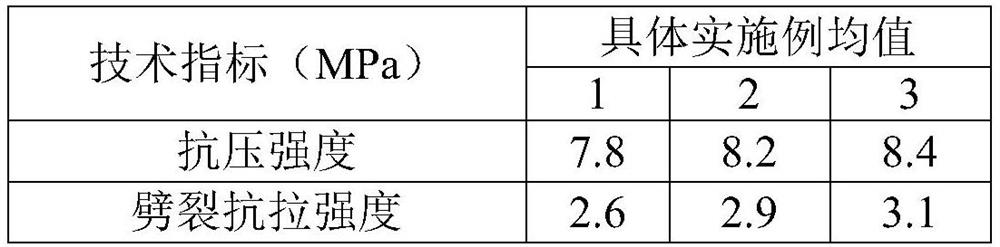

specific Embodiment 1

[0048] LC5: 260kg of cement, 60kg of fly ash, 500kg of machine-made sand, 1000kg of recycled fine aggregate, 190kg of water, 2.8kg of retarder, 5.3kg of water reducer, 4.8kg of sodium silicate, 1.8kg of fiber material (a cubic density can be Do 1500kg-1900kg).

specific Embodiment 2

[0049] LC7.5: cement 270kg, fly ash 60kg, machine-made sand 460kg, recycled fine aggregate 990kg, water 195kg, retarder 2.8kg, water reducer 5.5kg, sodium silicate 4.9kg, fiber material 1.9kg (one cubic The bulk density can be 1500kg-1900kg).

Embodiment 3

[0051] LC10: cement 290kg, fly ash 80kg, machine-made sand 550kg, recycled fine aggregate 900kg, water 195kg, retarder 2.9kg, water reducer 6.1kg, sodium silicate 5.4kg, fiber material 2.1kg (a cubic density can be Do 1500kg-1900kg).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap