Tantalum carbide composite material

A composite material, tantalum carbide technology, applied in the direction of carbon compound, polycrystalline material growth, carbon preparation/purification, etc., can solve the problem of carbon material etching, etc., and achieve the effect of improving adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0057] Example 1 to Example 3

[0058] TaC was deposited on the graphite substrate using chemical vapor (CVD) deposition.

Example

[0059] Comparative Example 1 to Comparative Example 4

[0060] TaC was deposited on the graphite substrate using chemical vapor (CVD) deposition.

[0061] property analysis

[0062] (1) Analysis of surface microstructure

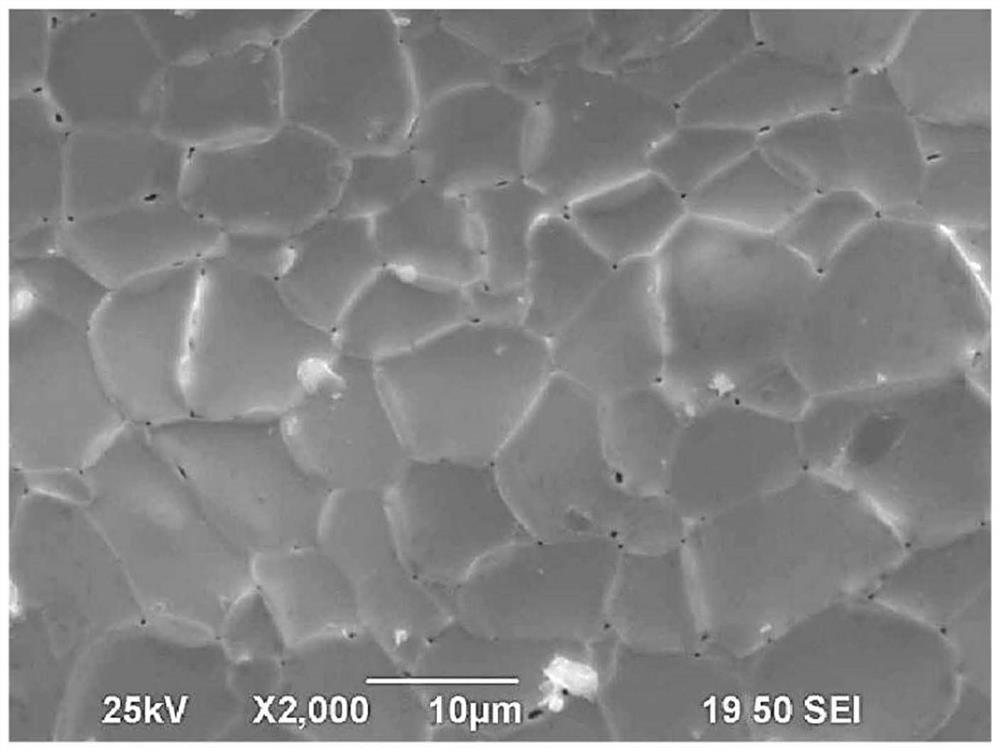

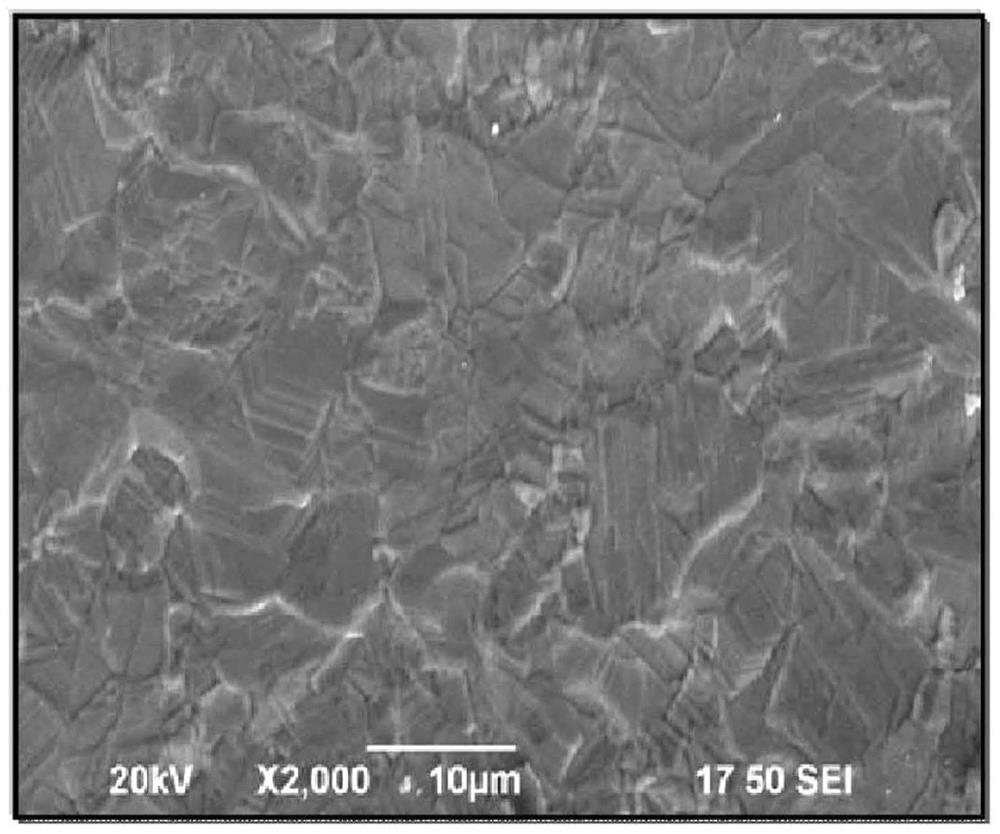

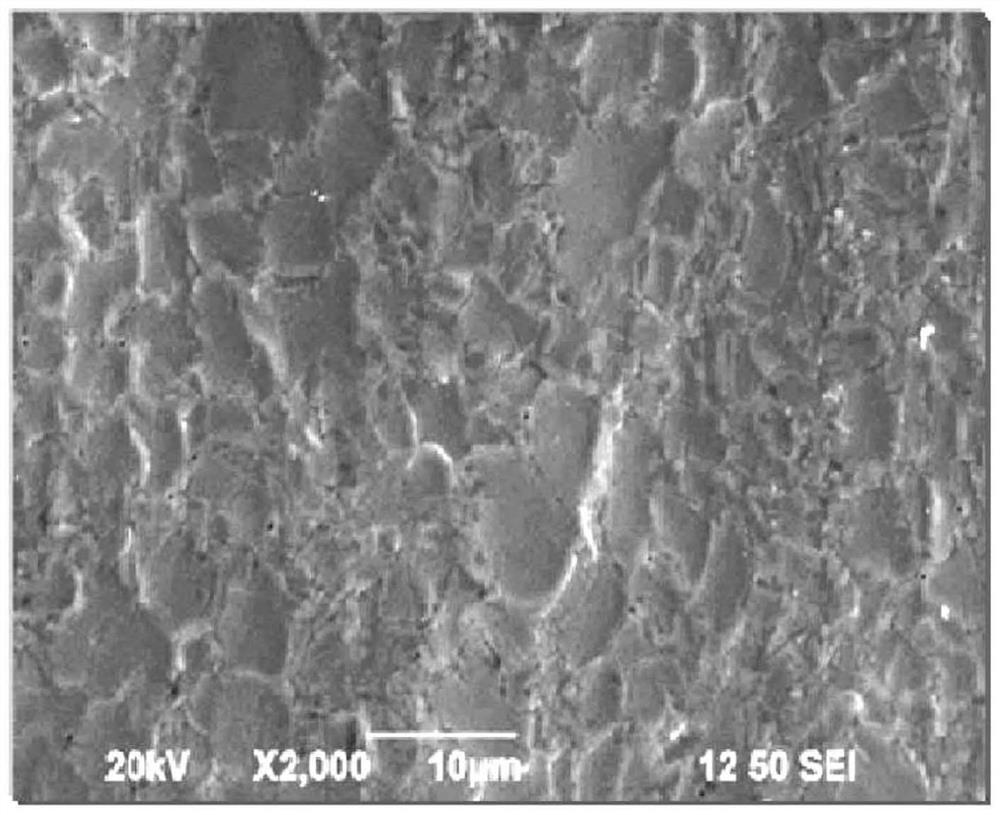

[0063] The surface microstructures of TaC prepared in Examples and Comparative Examples were observed by SEM, and the results are shown in Table 1 and Figure 1 to Figure 3 shown. In addition, in Table 1, the composition ratio of Ta and C is data measured by EDS, and is based on atomic (Atomic) % (model name: Oxford INCA x-act).

[0064] [Table 1]

[0065] Classification Comparative Example 1 Comparative Example 2 Example 1 Example 3 C(at%) 37.57 59.48 42.68 52.68 T(at%) 62.43 40.52 57.32 47.32 Ta / C 1.66 0.68 1.34 0.90 Surface shape of TaC particles wrinkled slightly wrinkled smooth smooth

[0066] Referring to Table 1, it can be seen that when the TaC surface microstructure is observed accor...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap