Self-propelled small laying machine for reed grass checks

A self-propelled, reed-grass technology, applied in planting methods, transplanting machinery, digging/covering ditches, etc., to achieve the effect of simple and exquisite structure, wide applicability, and reduce labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

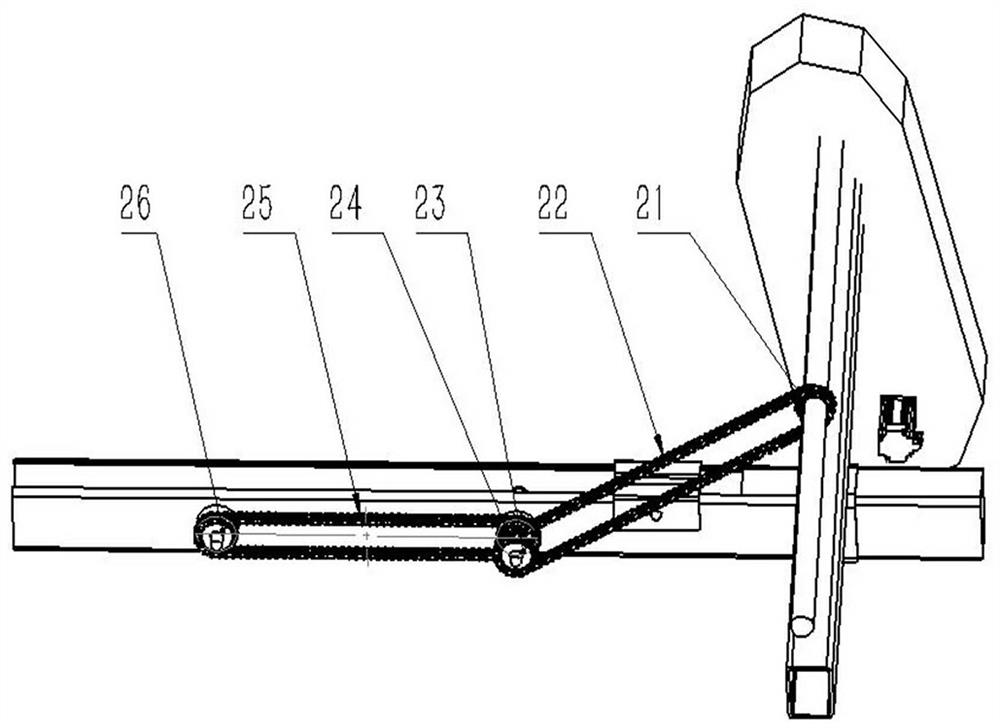

[0023] Among them, the front working surface of the ditch opener 10 is an anti-push and rent-reducing curved surface, and the side plates are longer to prevent sand backflow, cooperate with the baffle plate 8 of the planter and the planting pincers 36, and the covering wheel 9 is a curling disc, square Seat 29 and outer spherical bearing 230 preferably realize that the soil-covering wheel becomes 10 °-20 ° angle, and seat 5 is fixed on the center of the implement by seat support frame 37 and bracket 40, and seat support frame 37 relies on bearing support 38 and machine tool center. The opener 10 is connected up and down with the bracket, the material box 6 is fixed on the right side of the seat through the material box bracket 4, the upper end of the planter baffle 8 is an open arc surface, and the bottom is the baffle 41, and the side of the baffle 41 is connected. Material box support 42.

[0024] In the description of this specification, descriptions with reference to the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com