Manufacturing method of semiconductor device

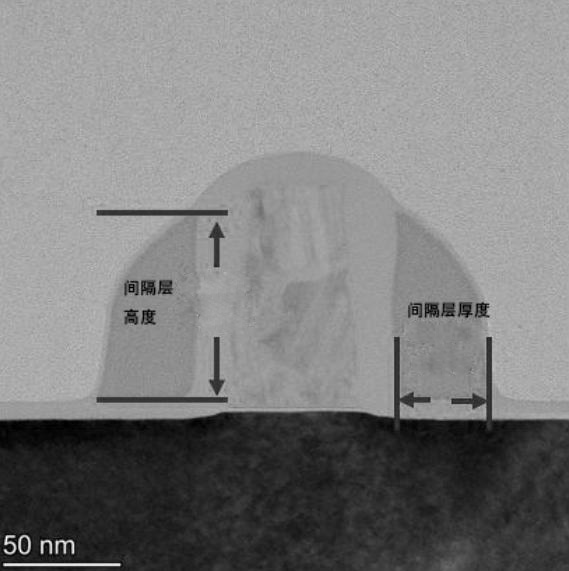

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effect of avoiding thickness reduction and height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

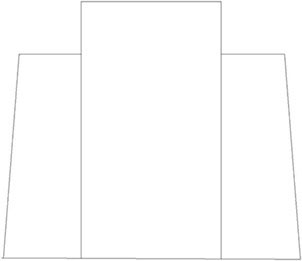

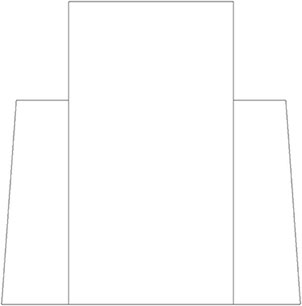

[0034] S6, performing ion implantation on the semiconductor substrate 1 using the remaining spacer layer 3 and the polysilicon 2 as a mask.

[0035] Wherein, as an example, the polysilicon 2 can be the gate of a MOS device. In step S6, using the spacer layer 3 and the polysilicon 2 as a mask, after ion implantation is performed on the semiconductor substrate 1 on both sides of the polysilicon, the polysilicon 2. A source region (not shown) and a drain region (not shown) of a MOS device are respectively formed in the semiconductor substrate 1 on both sides.

[0036] To sum up, in the manufacturing method of the semiconductor device provided by the embodiment of the present invention, by using the protective layer to protect the root of the spacer layer, on the basis of reducing the height of the spacer layer, it avoids the problems caused by conventional isotropic etching. Side effect of reduced spacer layer thickness.

[0037] The above description is only a description of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com