Preparation method of high-temperature alloy free forging bar billet for ultra-supercritical thermal power generating unit

A technology of thermal power units and high-temperature alloys, applied in metal processing equipment, manufacturing tools, heating/cooling equipment, etc., can solve problems such as easy crack formation, scrapped pipes, unevenness, etc., and achieve the goal of improving grain size and structure uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

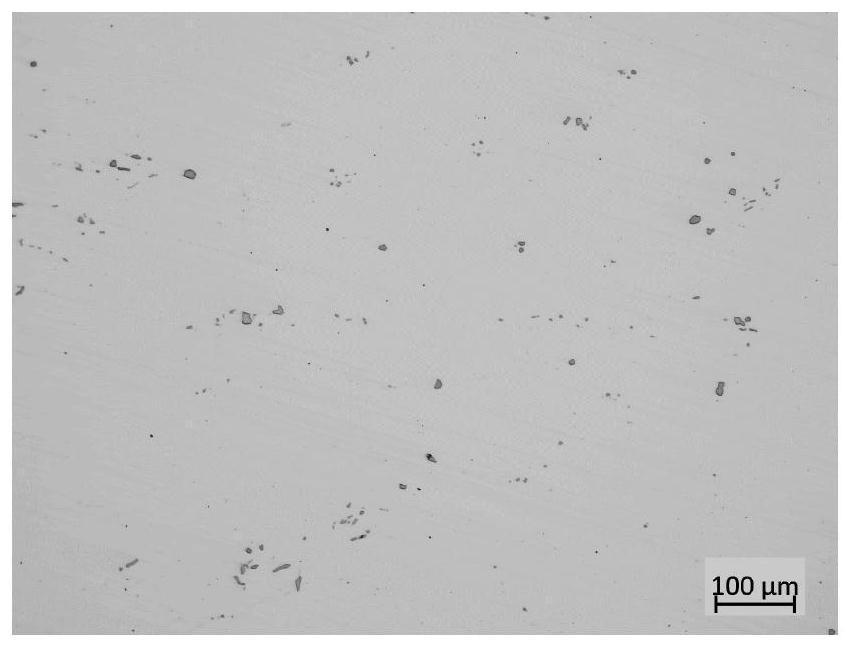

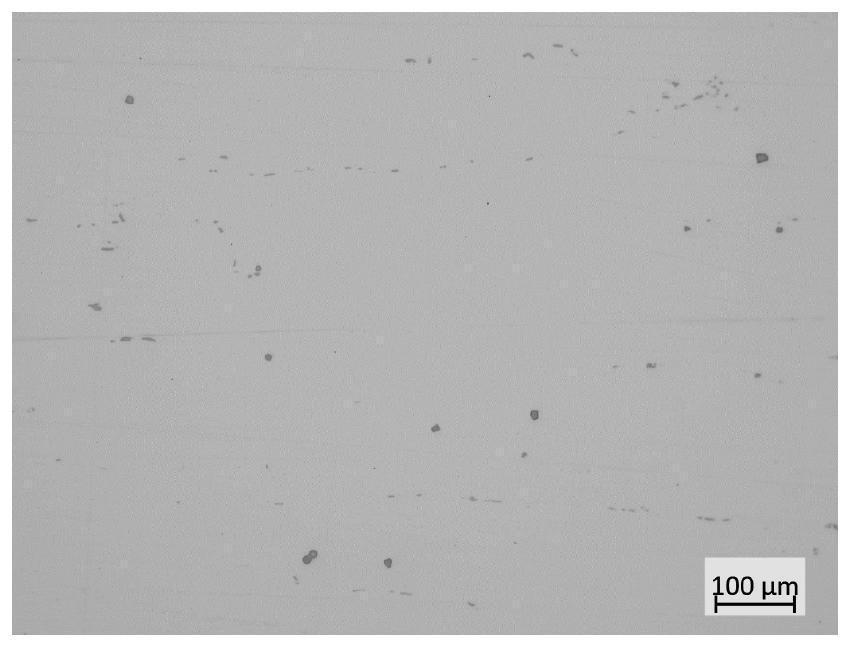

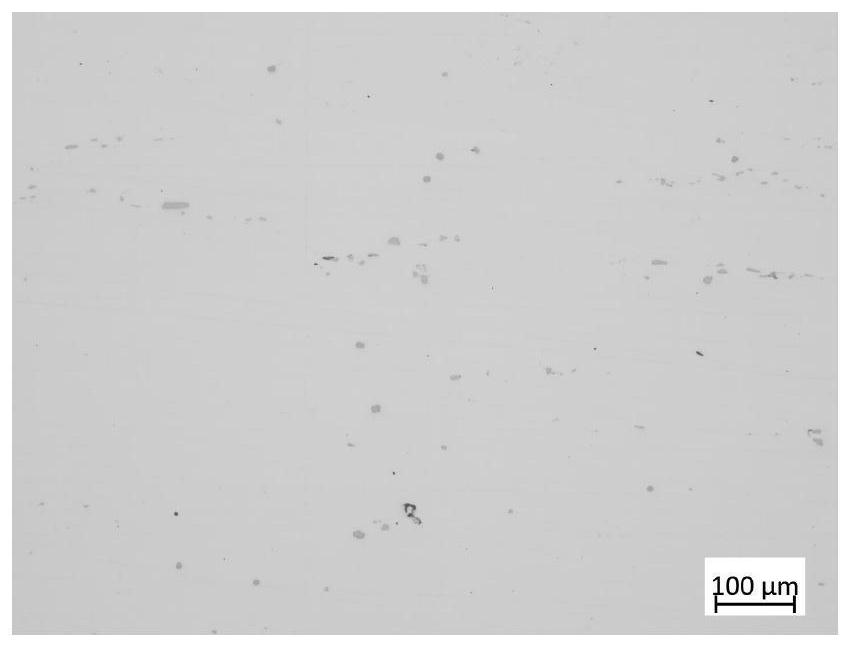

Image

Examples

Embodiment

[0028] The diameter of the superalloy ingot for ultra-supercritical thermal power unit smelted by vacuum induction melting + vacuum consumable remelting process is 490mm. The ingot homogenization process is as follows: heating to 700 ° C, holding for 300 min, and then heating at 5 ° C / min The temperature was raised to 1150°C, the holding time was 24h, and then the temperature was raised to 1195°C at a heating rate of 5°C / min, and the holding time was 48h.

[0029] After the ingot is kept at 1120-1170 ℃, the billet is opened, and the billet is forged for a total of 2 fires. The first fire is upsetting, and the second fire is drawn and upsetting. The deformation settings are as follows: Φ490×1400→Φ610×930→Bafang 550× 1050→Bafang 700×650, the deformation amount of the first fire is 35%, the deformation amount of the drawing and upsetting in the second fire is 14% and 38%, respectively. After completion, the hot material is returned to the furnace.

[0030] After the billet is kep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com