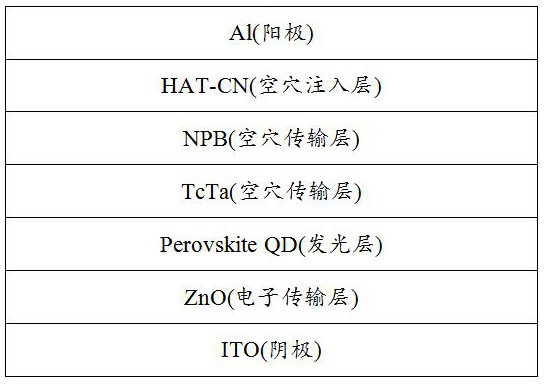

Inverted-structure perovskite QLED device based on photoetching technology and preparation method thereof

An inverted structure and photolithography technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as instability, incompatible surface ligands, and affecting the application of perovskite QLED devices, and achieve Achieving a patterned effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

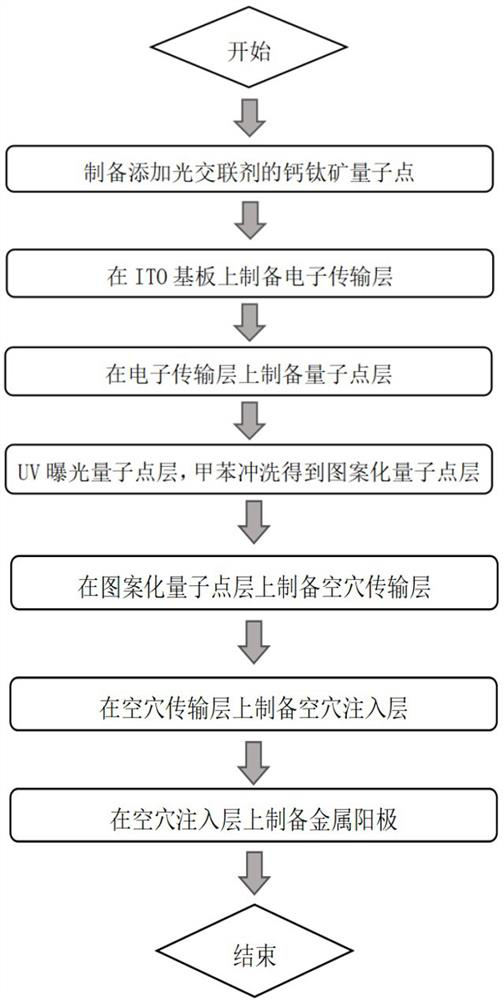

[0021] 2) Put the cathode substrate into glass cleaning agent, deionized water, acetone, and ethanol in sequence for ultrasonic treatment, and the time for each ultrasonic is 10 minutes.

[0022] 3) ZnO was prepared as an electron transport layer by spin-coating method with an annealing temperature of 150 °C and a thickness of about 50 nm.

[0023] 4) Spin-coat perovskite quantum dots added with a photocrosslinking agent on the surface of the electron transport layer by spin coating as a patterned quantum dot layer, with a thickness of about 30 nm. The quantum dot ligands in the exposed part are crosslinked under UV light through a photolithography process, rinsed with toluene after exposure, and what remains is the patterned quantum dot layer after the crosslinking of the quantum dot ligands.

[0024] 5) Evaporate TcTa as a hole transport layer by vacuum evaporation method, and its thickness is 30 nm.

[0025] 6) Evaporate NPB as a hole transport layer by vacuum evaporation ...

Embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com