Plasma arc waste residue incineration device

A plasma arc and waste slag technology, applied in transportation and packaging, solid waste removal, chemical instruments and methods, etc., can solve the problems of reducing heat loss and low incineration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

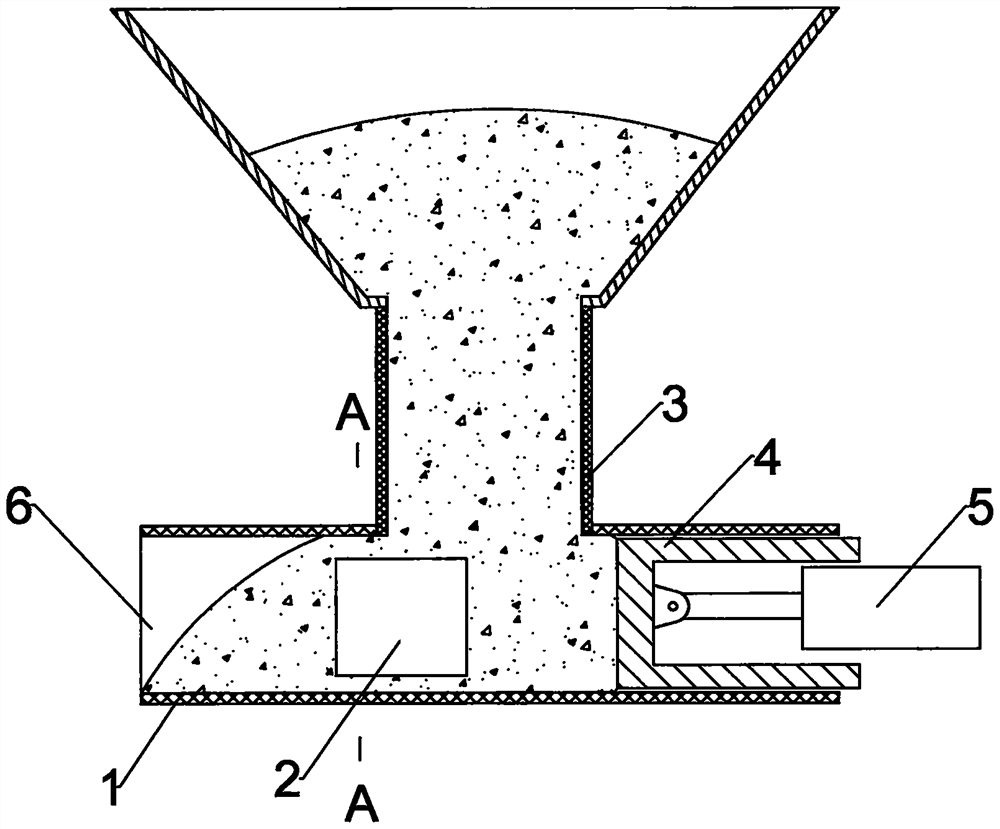

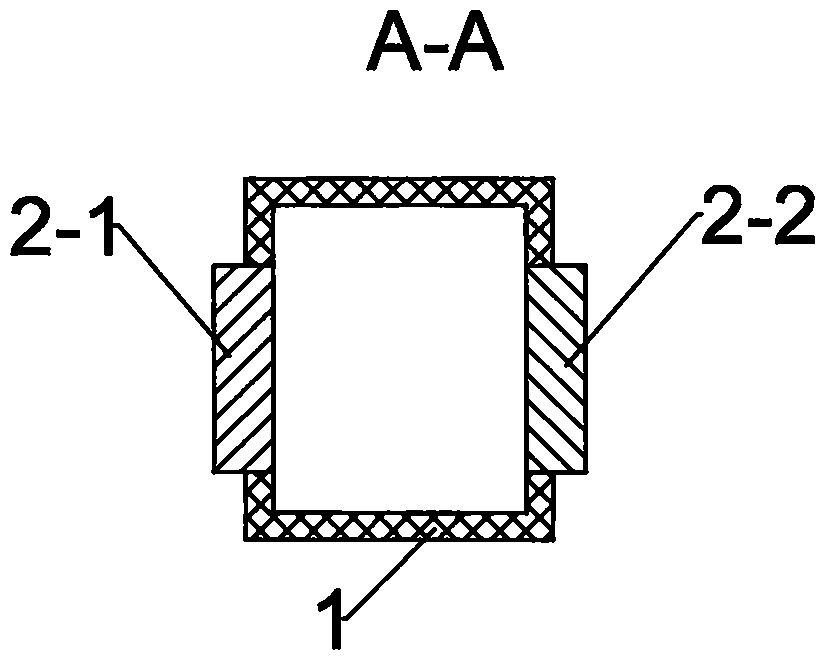

[0012] in as figure 1 , figure 2 In the first embodiment shown, the electrode group 2 is arranged horizontally opposite to both sides of the insulating flow channel 1 made of heat-resistant material, and the electrode group 2 is composed of a first electrode 2-1 and a second electrode 2-2, The arc generated by the two electrodes is in a horizontal direction. The blanking tube 3 is arranged above the electrode group 2, and the falling material can bury the arc. There is a pusher 4 at the back of the blanking tube 3. Driven by the motor 5, the reciprocating motion makes the slag in front of it push forward intermittently in the direction of the arc. A part of the waste slag burned by the arc will be melted into a glass body, and the glass body and the unburned waste slag will be pushed out from the discharge port 6 together.

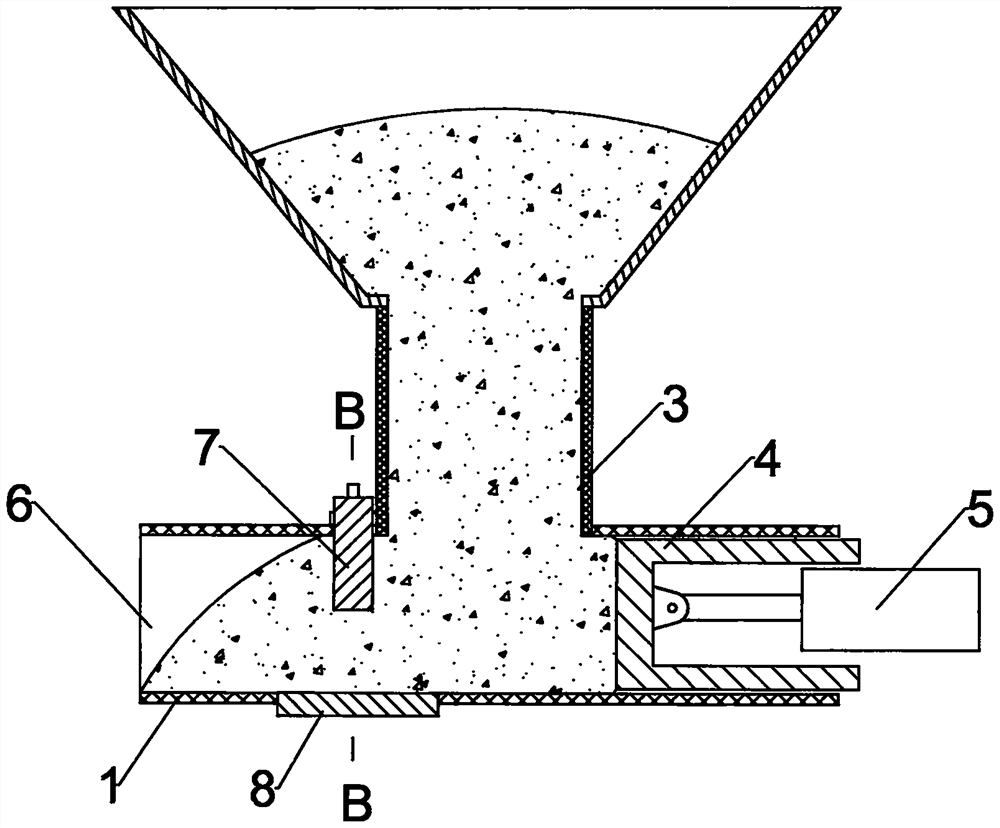

[0013] in as image 3 , Figure 4 In the second embodiment shown, the upper electrode 7 and the lower electrode 8 are vertically opposed to the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com