Photovoltaic tile assembly and preparation method thereof

A photovoltaic tile and component technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of inconvenient construction and installation, low component power, complex process, etc., and achieve the effect of easy disassembly and maintenance, various forms, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments.

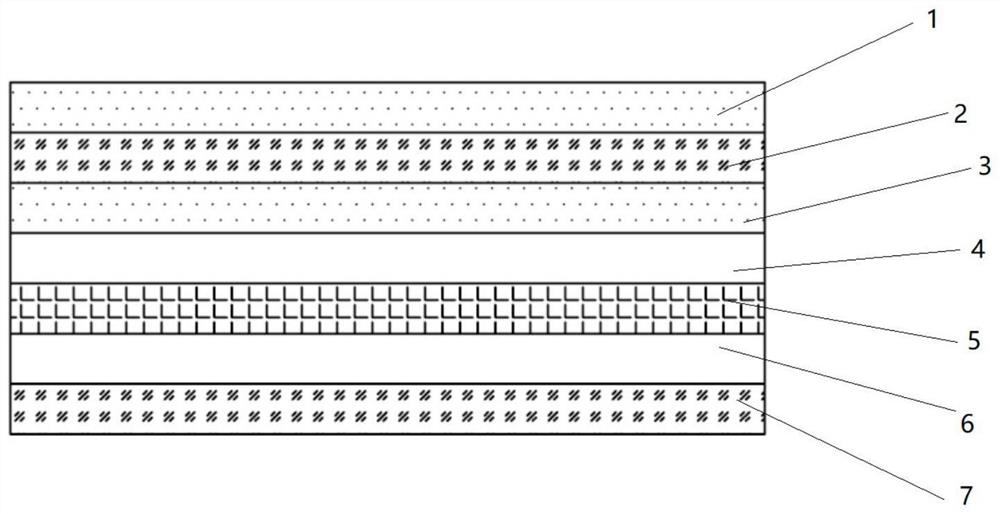

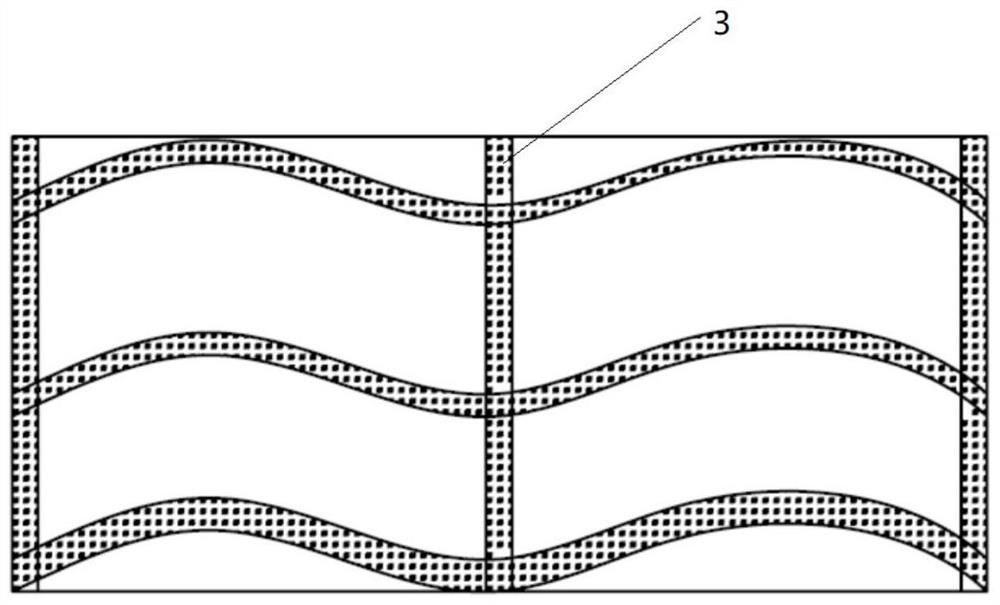

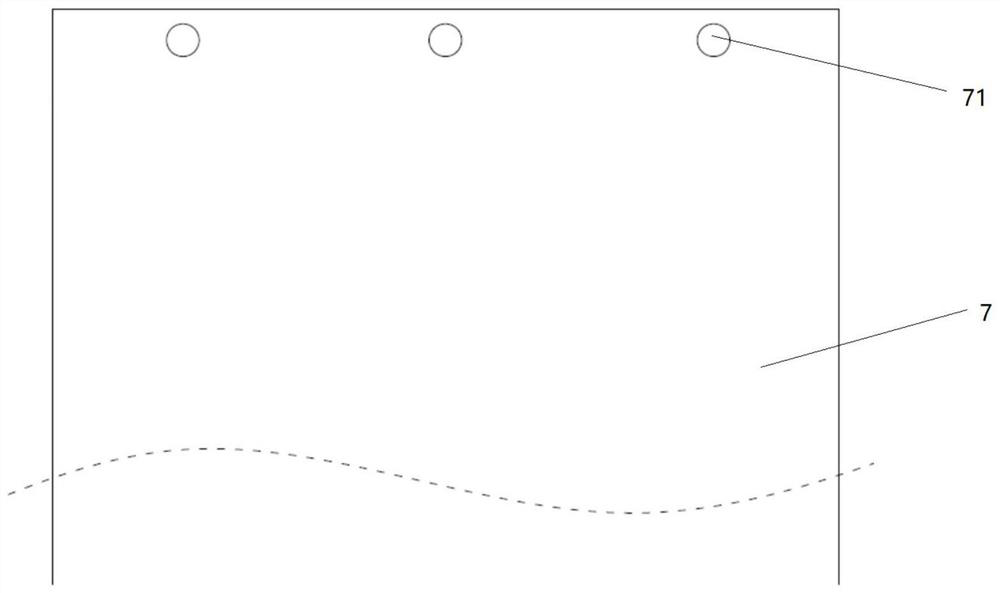

[0020] like Figure 1-3 As shown, this embodiment provides a photovoltaic tile assembly, including a first glass layer 2, a first encapsulation film layer 4, a battery string layer 5, a second encapsulation film layer 6 and a second glass layer that are stacked in sequence. 7, wherein, a coating pattern layer 3 is provided on the surface of the first glass layer 2 close to the first encapsulation adhesive film layer 4, and an anti-reflection coating layer 1 is provided on the other surface.

[0021] Preferably, the anti-reflection coating layer 1 is a SiO2 anti-reflection coating, using the currently mature technology to add a nano-SiO2 anti-reflection coating on the upper surface of the tempered glass, and then through a heat treatment process to make the film and the glass substrate firmly combined, so that The light transmittance of coate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com