Electrode for hydrogen evolution by electrolyzing water and device and method for hydrogen production by electrolyzing water

A technology of hydrogen evolution electrode and hydrogen production device, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve environmental problems, CO poisonous gas, consumption of fossil energy and other problems, reduce the cost of electricity for hydrogen production, and improve the efficiency of hydrogen production , The effect of reducing electricity costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

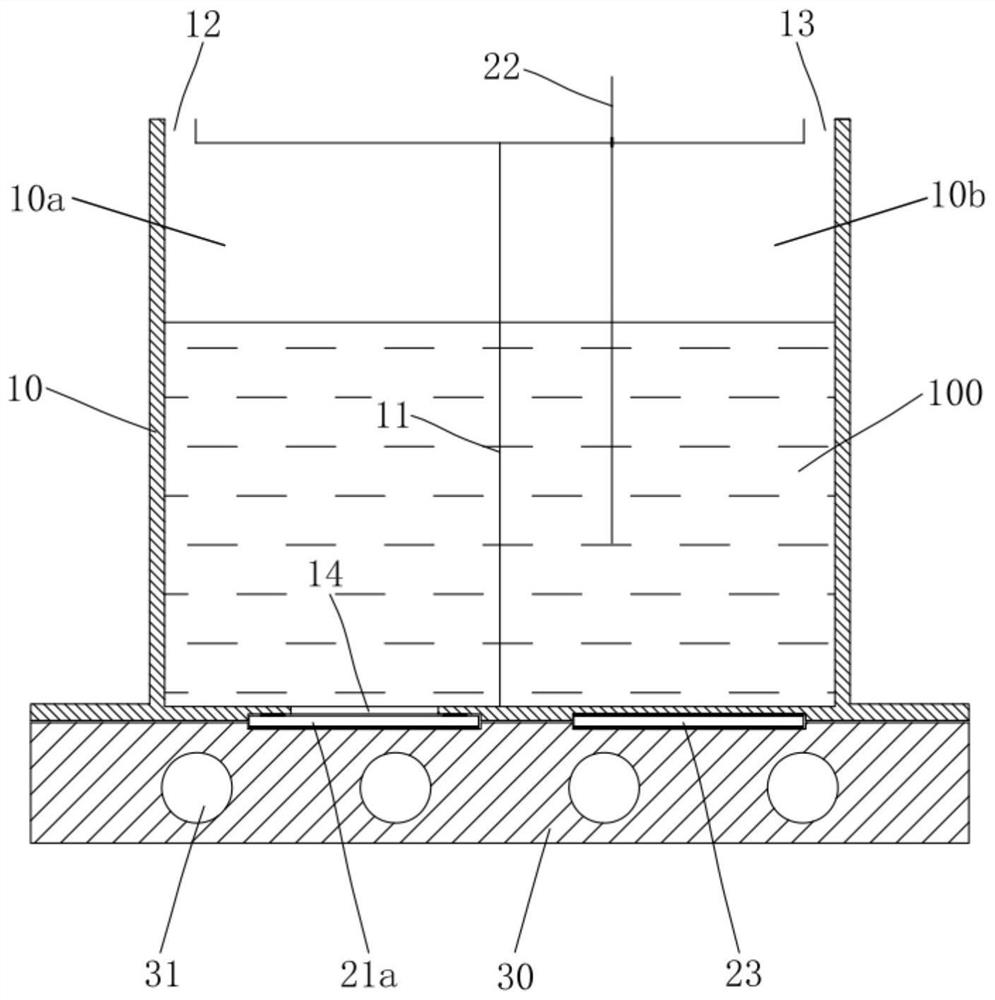

[0031] like figure 1 As shown, the electrolytic water hydrogen production device of Embodiment 1 includes an electrolytic cell 10, a hydrogen-evolution electrode 21a and an oxygen-evolution electrode 22; The proton exchange membrane 11 is divided into a first space 10a and a second space 10b, the first space 10a has a hydrogen gas discharge channel 12, and the second space 10b has an oxygen gas discharge channel 13; the hydrogen evolution electrode 21a as the cathode electrode is located in the first space 10a, The oxygen evolution electrode 22 as the anode electrode is located in the second space 10b.

[0032] A heat dissipation module 30 is disposed below the electrolytic cell 10 . The heat dissipation module 30 may be made of metal material, and a heat dissipation fluid channel 31 may be provided in the interior of the heat dissipation module to accelerate heat dissipation. Further, a thermoelectric conversion module 23 may be provided between the electrolytic cell 10 and ...

Embodiment 2

[0042] The main difference between Example 2 and Example 1 is that in Example 2, an integrated design is carried out on the hydrogen evolution electrode for electrolysis of water and the thermoelectric conversion module. Below, only the difference between embodiment 2 and embodiment 1 is described, other parts can refer to embodiment 1.

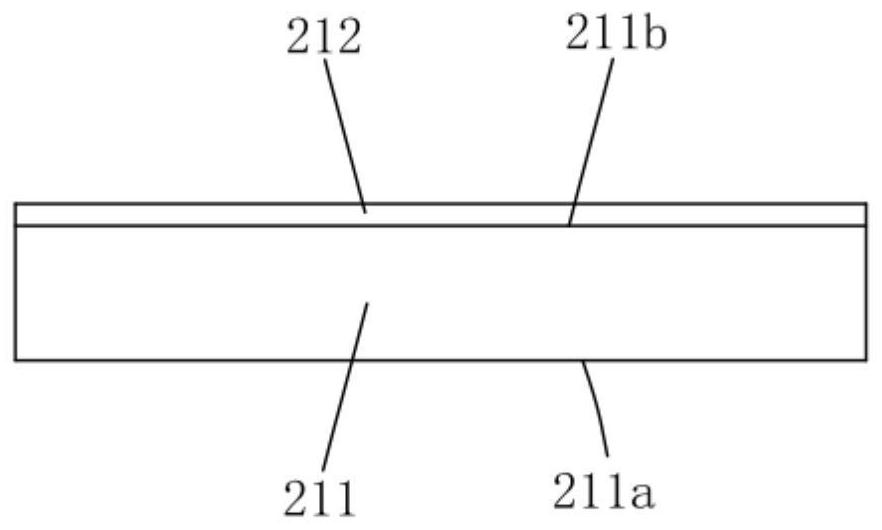

[0043] Specifically, as Figure 7 and 8 As shown, in Embodiment 2, the hydrogen evolution electrode 21b itself includes a thermoelectric conversion module 213, and the package body 2132 of the thermoelectric conversion module 213 is provided with a plurality of P-type thermoelectric conversion elements 2131P and a plurality of N-type thermoelectric conversion elements 2131N, and the P-type thermoelectric conversion elements 2131N. The conversion element 2131P and the N-type thermoelectric conversion element 2131N are alternately arranged and connected in series through the conductive sheet 2133; wherein, the P-type thermoelectric conversion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com