Detection method and evaluation method for residual life of anti-corrosion alloy coating on heating surface of waste incineration boiler

An anti-corrosion alloy and waste incineration technology, applied in the direction of measuring devices, test metals, material inspection products, etc., can solve the problems of not being able to find corrosion-prone areas, unrepresentative measurement areas, and a large amount of furnace content, etc., to ensure a long cycle The effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

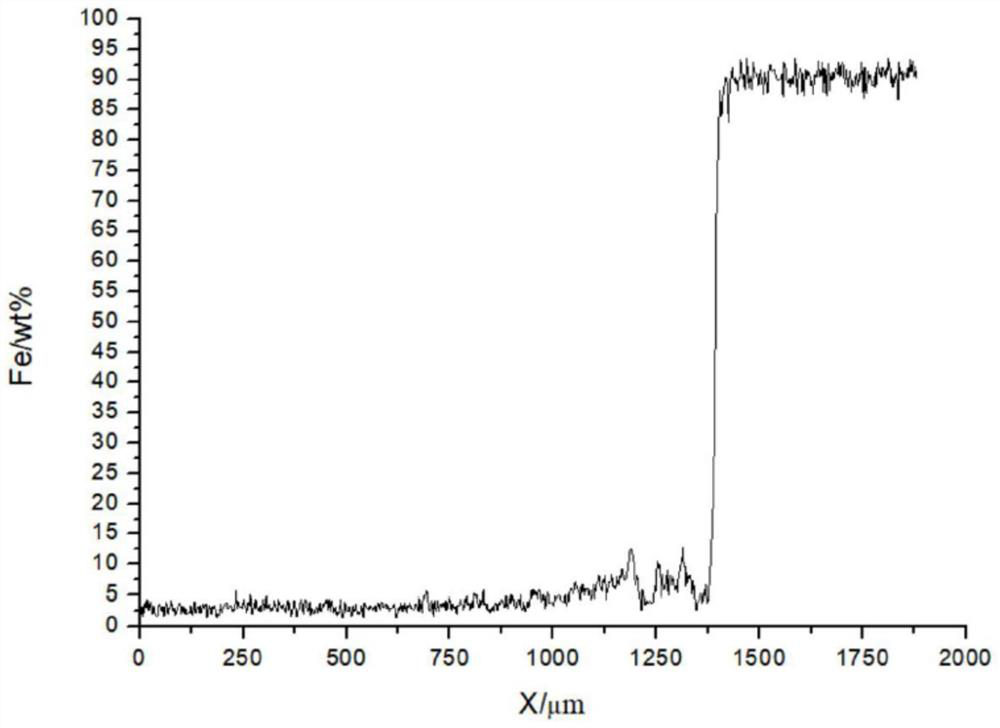

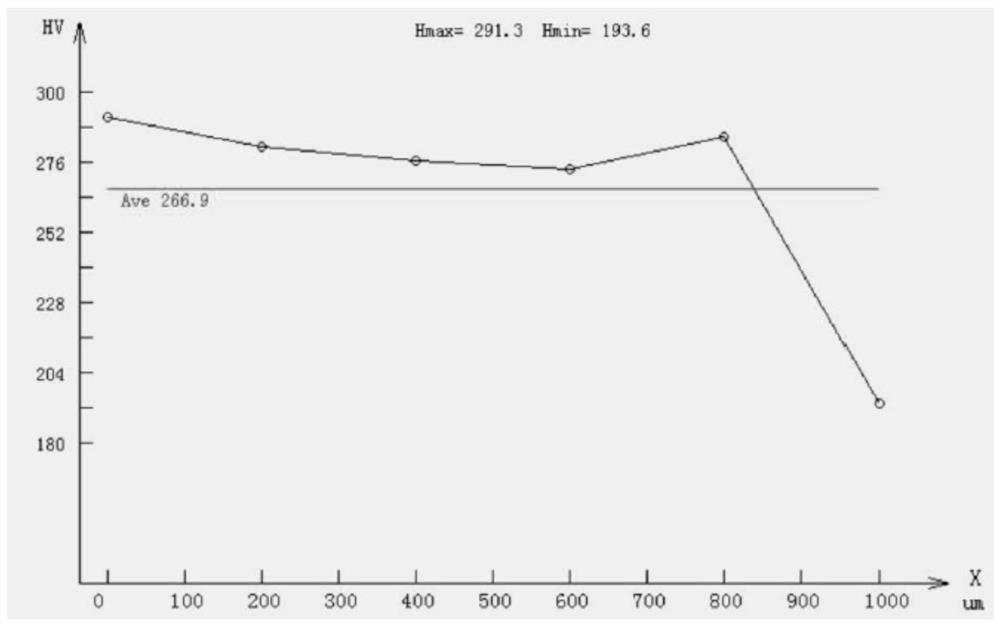

[0066] The anti-corrosion alloy coating adopts the laser cladding 625 processing technology, of which 625 is the anti-corrosion alloy powder material. It is necessary to analyze the application of the laser cladding 625 anti-corrosion alloy coating on the heating surface of the waste incinerator, evaluate its actual durability, and evaluate whether maintenance is required. Cut the sample to obtain the cross-sectional hardness and composition of the coating as a function of thickness, such as figure 1 , figure 2 It can be seen that with the decrease of the residual thickness, the Fe content in the coating gradually increases, and the hardness also shows a downward trend. When the surface Fe content exceeds 10%, and the hardness is significantly less than HV266.9, it means that the anti-corrosion coating The residual thickness is significantly less than the safe thickness and needs to be repaired.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com