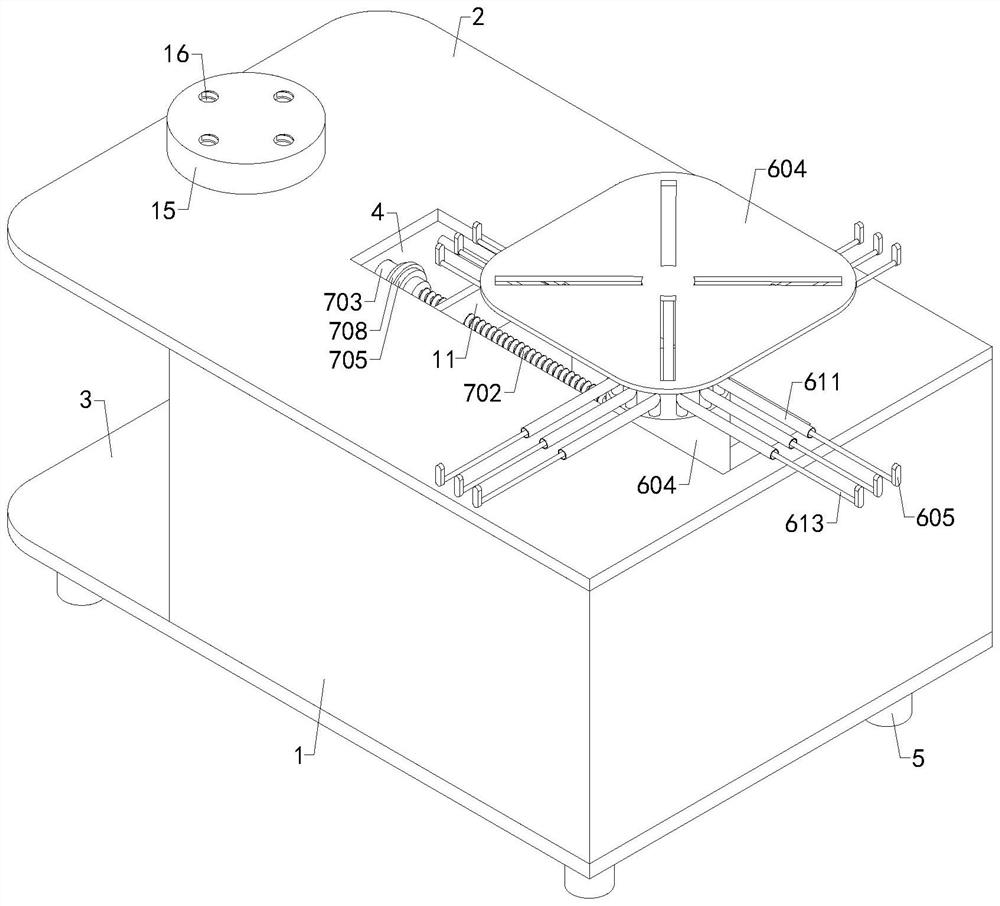

Intelligent part welding and fixing equipment for research, development and manufacturing of electronic components

A welding technology for electronic components and parts, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effects of reducing participation, saving time, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

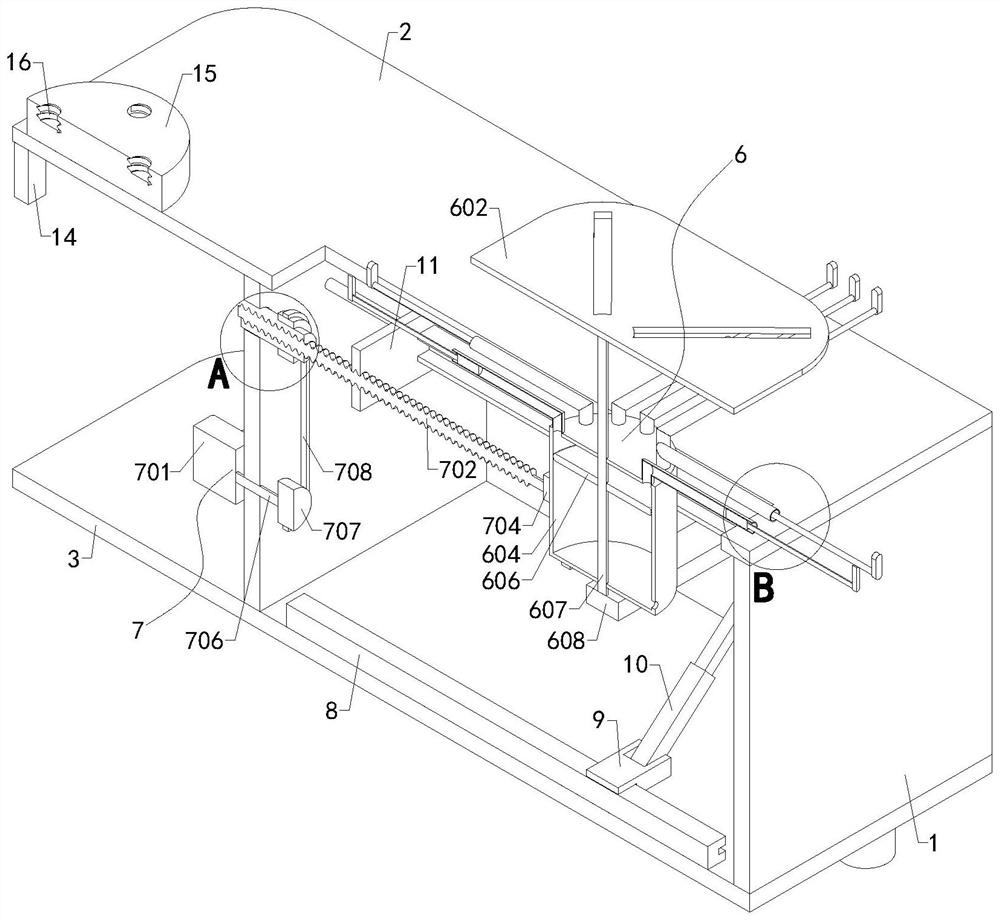

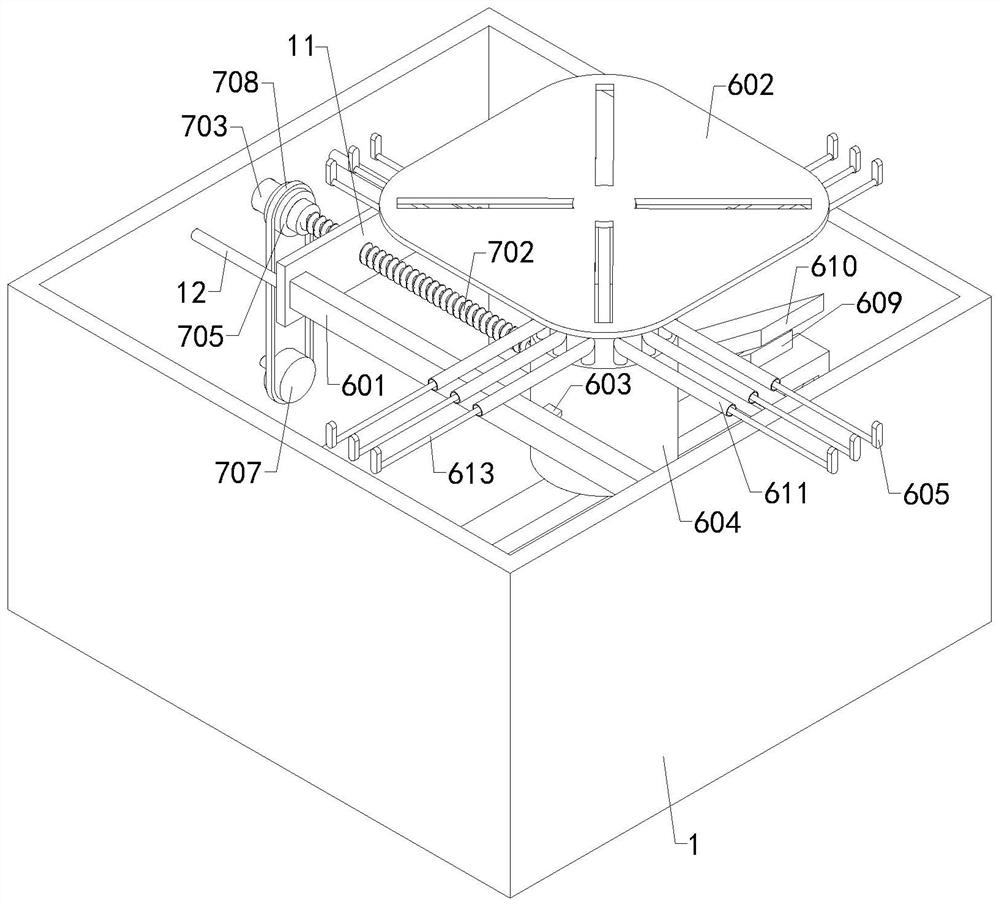

[0030] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

[0031] In the intelligent parts welding and fixing equipment developed and manufactured by the electronic components of the present invention, the installation methods, connection methods or setting methods of all the above-mentioned components are common mechanical methods, and the specific structures, models and coefficient indicators of all the components are Its own technology can be implemented as long as it can achieve its beneficial effects, so it will not be repeated.

[0032] The intelligent parts welding and fixing equipment developed and manufactured by the electronic components of the present invention, unless otherwise stated, the orientation words included in the terms such as "up...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap