Anti-backflow adjustable water distributor

A water trap and anti-return technology, which is applied in the direction of wellbore/well components, production fluid, sealing/package, etc. It can solve the problems of inability to prevent regurgitation and achieve the effect of small radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

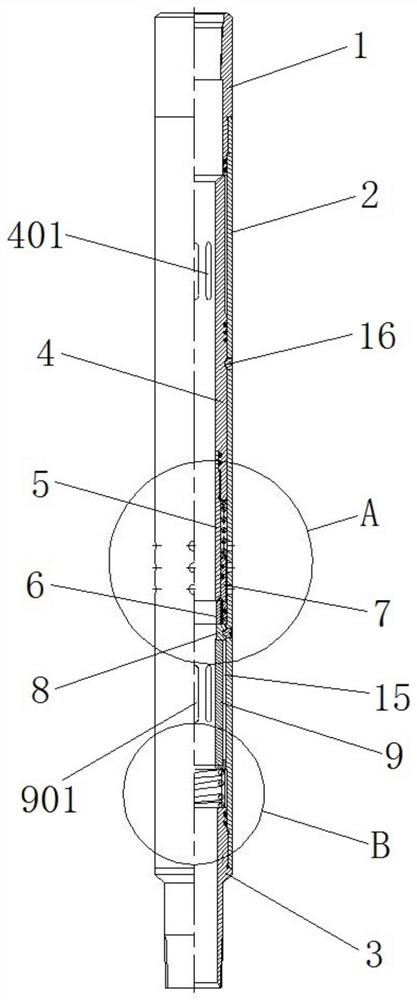

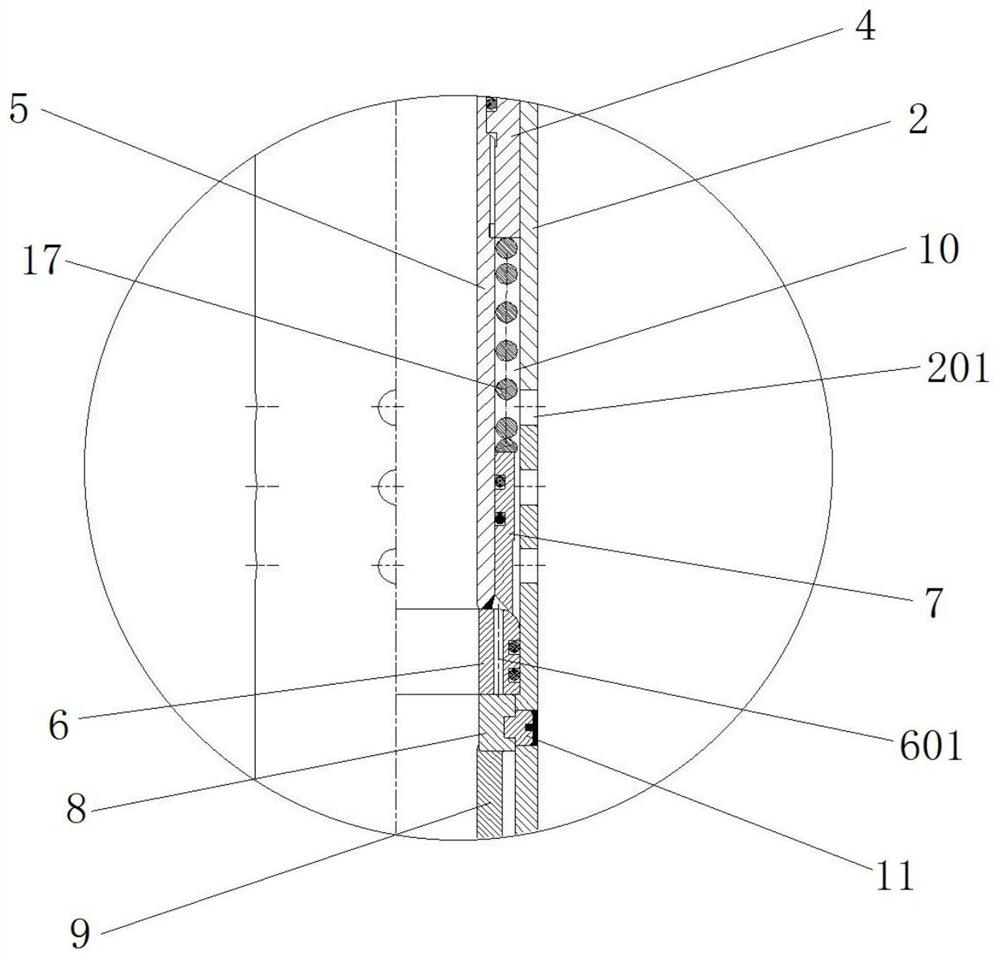

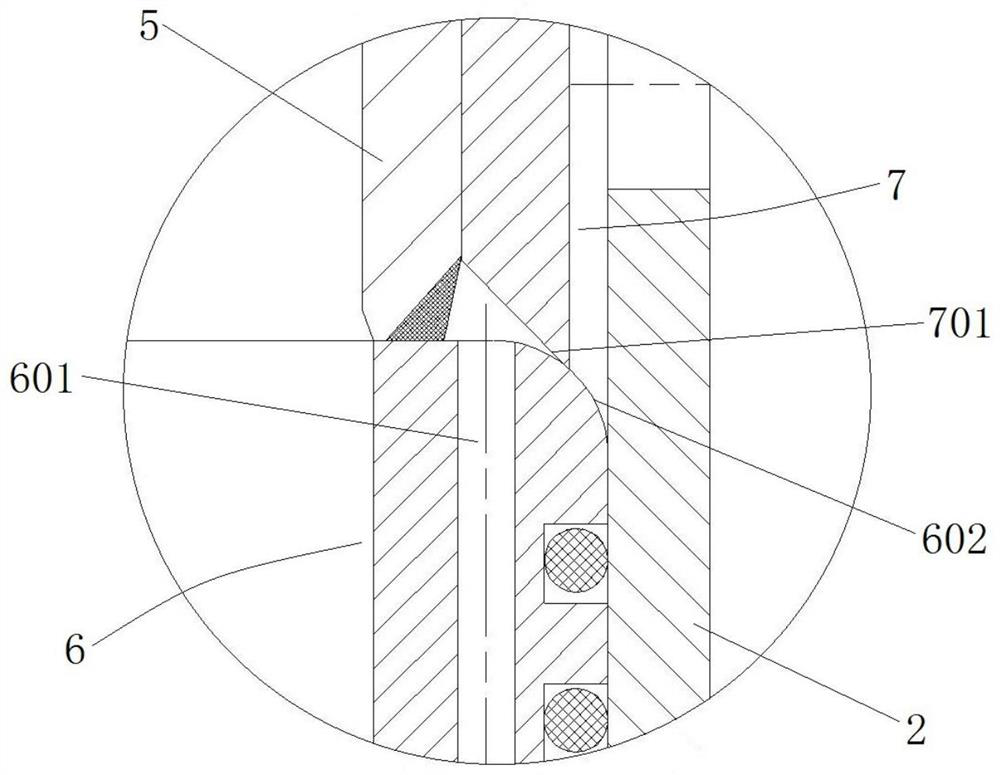

[0038] like Figure 1 to Figure 11 As shown in the figure, the anti-returning adjustable water distributor (hereinafter referred to as the water distributor) is applied in a small diameter casing, including an upper joint 1, an outer cylinder 2 and a lower joint 3 which are connected in sequence from top to bottom, and the three threaded Assembled together, and a sealing ring is installed at the connecting position, the outer cylinder 2 is sequentially arranged with a positioning pipe 4, an anti-rotation pipe 5, a fixed valve plate 6, a rotary valve plate 8, and a rotating core 9 from top to bottom. .

[0039] The positioning tube 4 is fixedly installed on the outer cylinder 2. Specifically, there are 6 pin holes evenly distributed along the circumferential direction on the outer wall of the positioning tube 4, and 6 screw holes are correspondingly opened on the outer cylinder 2. In each screw hole and pin hole The second pins 16 are all worn, and the positioning tube 4 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com