Device for laying denitration catalyst on ceramic filter element

The technology of denitration catalyst and ceramic filter element is applied in the device, chemical instrument and method, separation method and other directions of coating liquid on the surface, which can solve the problems of inability to ensure the uniformity and laying of liquid catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

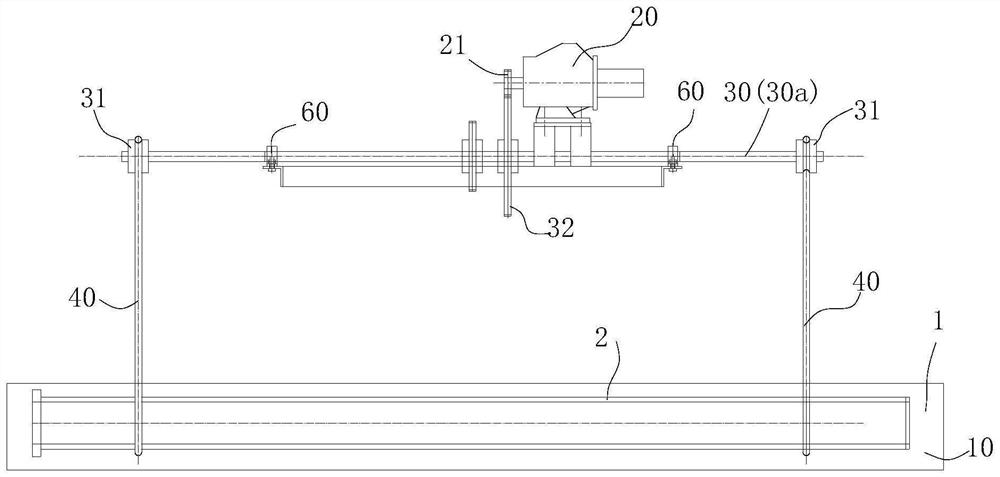

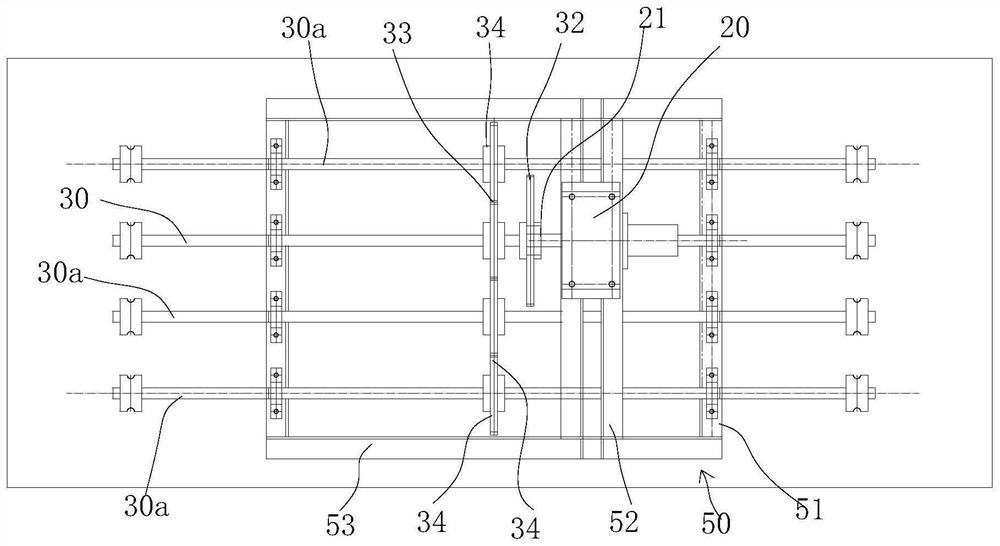

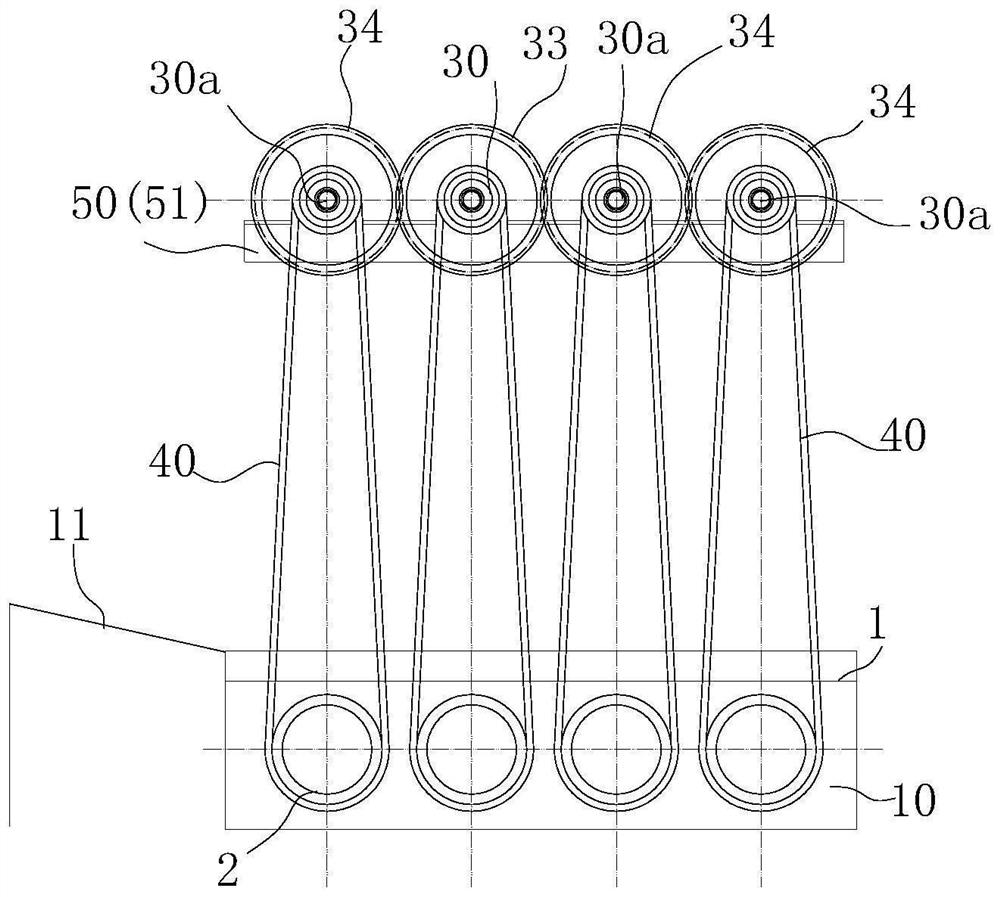

[0015] like figure 1 , 2 As shown in 3 and 3, the device for laying the denitration catalyst on the ceramic filter element includes a liquid medicine pool 10 containing the denitration catalyst liquid medicine 1. Above the pool mouth of the liquid medicine pool 10 is a main rotating shaft 30 driven by a motor 20. The main rotating shaft 30 is arranged horizontally, and the annular soft The upper end of the belt 40 is hung on the main rotating shaft 30, the annular soft belt 40 is of equal length and is arranged at several intervals along the length direction of the main rotating shaft 30, and the lower end of the annular soft belt 40 is hung around the ceramic filter element tube 2 to be treated. On the tube body, the ceramic filter tube 2 is immersed in the denitration catalyst liquid 1.

[0016] Since most of the denitration catalysts contain heavy metal oxides and have a high density, the aqueous solution cannot be left standing after stirring evenly, otherwise it is easy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com