Estimation device, vacuum valve, and vacuum pump

A deduction device and vacuum pump technology, applied in the direction of pumps, axial flow pumps, pump control, etc., can solve problems such as inability to rotate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach -

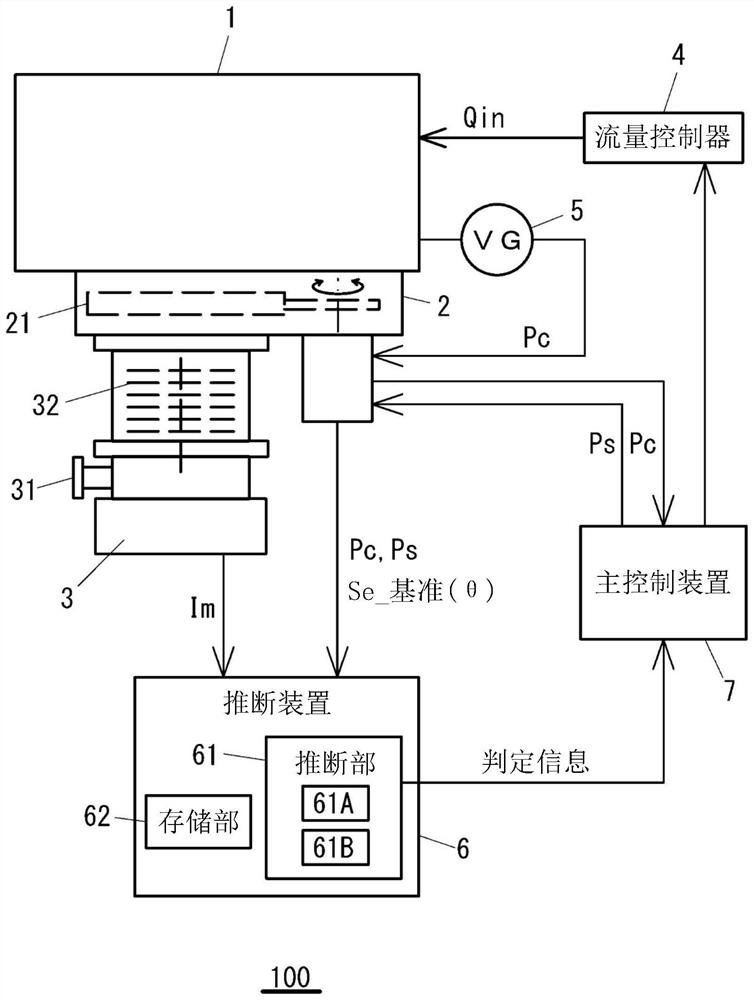

[0043] figure 1 This is a block diagram showing a schematic configuration of the vacuum processing apparatus 100 . Examples of the vacuum processing apparatus 100 include an etching apparatus, a film forming apparatus, and the like. The vacuum processing apparatus 100 includes a vacuum chamber 1 for performing a process, a vacuum valve 2 installed in the vacuum chamber 1 , a vacuum pump 3 installed in the vacuum chamber 1 via the vacuum valve 2 , and a control for the gas introduced into the vacuum chamber 1 . The flow controller 4 for controlling the flow rate of the vacuum chamber 1 , the vacuum gauge 5 for measuring the pressure of the vacuum chamber 1 , the estimation device 6 , and the main control device 7 for controlling the vacuum processing apparatus 100 .

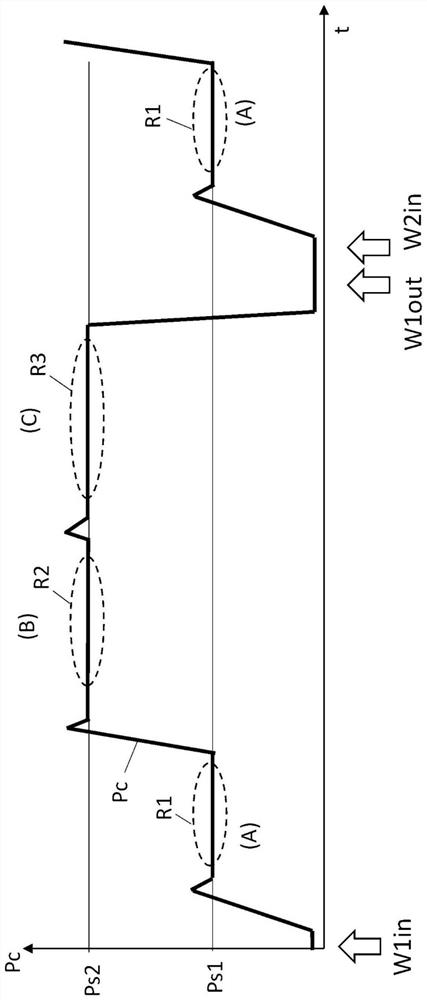

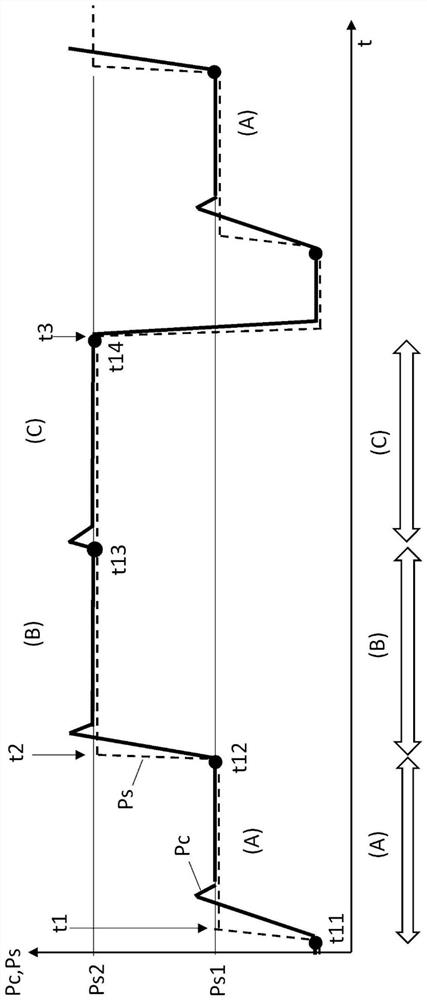

[0044] The vacuum valve 2 is an automatic pressure control valve, which automatically adjusts the opening degree θ of the valve body 21 so that the chamber pressure Pc becomes Target pressure Ps. The vacuum val...

Deformed example 1

[0145] In the above-described embodiment, it is assumed that the process information data set is generated, the accumulation information data set obtained by adding the motor current value Im input from the vacuum pump 3 to the process information data set is generated, and the accumulation information data used for the determination of the accumulation amount is assumed. The extraction of the set and the determination of the accumulation amount based on the extracted accumulation information data set are all performed by the inference device 6 . However, for example, a determined data set (a data set containing only process gas conditions) for each process event that does not contain the motor current value Im can be sent from the inference device 6 to the vacuum pump 3 or the vacuum valve 2, and at the vacuum pump 3 or vacuum In the valve 2 , the determination of the accumulation amount is performed by adding the motor current value Im and the measurement time Time_msr to the...

Deformed example 2

[0148] exist figure 1 In the system configuration shown, the estimating device 6 is connected in parallel with the vacuum pump 3 and the vacuum valve 2 through a communication line to acquire information from the vacuum pump 3 and the vacuum valve 2, but the vacuum pump 3 may be communicated via RS485 communication or the like. , the vacuum valve 2 and the inference device 6 are connected in sequence in a daisy-chain connection. The motor current value Im of the vacuum pump 3 is sent to the estimation device 6 via the vacuum valve 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com