Rapid calibration method and system for permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and calibration method, which is applied in the direction of control system, control generator, vector control system, etc., can solve the problems of burning power devices, controller DC voltage rise, over-modulation, etc., and achieve the simplification of the calibration process, The effect of saving bench resources and improving calibration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0055] The present invention will be described in detail below with reference to the accompanying drawings.

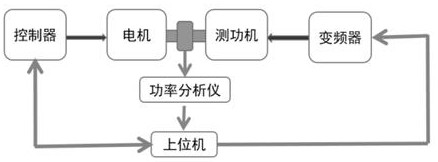

[0056] figure 2 Shown is a bench calibration system to realize the rapid calibration of permanent magnet synchronous motor: including controller, motor, dynamometer, frequency converter, power analyzer and upper computer.

[0057] Calibrate the host computer to control the inverter to work at a specific speed, and give the motor controller different , Current combination, control the motor work, collect feedback torque, current, voltage signals of the power analyzer, etc., and find the optimal current combination under different working conditions through a specific algorithm.

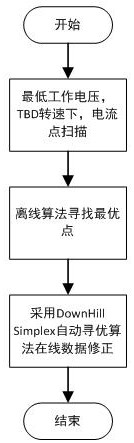

[0058] An embodiment of the present invention provides the main steps for realizing the rapid calibration of the permanent magnet synchronous motor, see figure 1 :

[0059] Step 1, online data collection: use the above system to scan different voltages at the minimum operating voltage re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap