Ammonium salt filled porous metal spontaneous perspiration composite material and preparation method thereof

A technology of porous metal and composite materials, which is applied to the device and coating of the surface coating liquid, which can solve the problems of unreasonable filling of cooling fluid and mismatching of temperature, and achieve low cost, large decomposition enthalpy, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation of ammonium salt filled porous metal spontaneous sweating composite material, comprising the following steps:

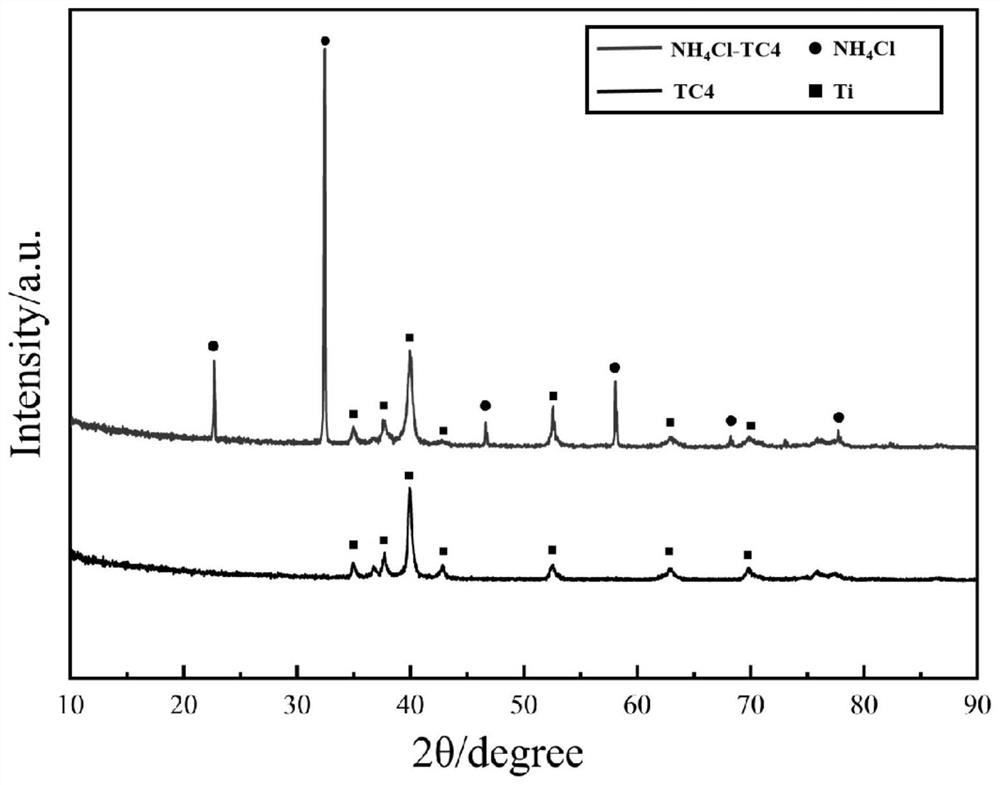

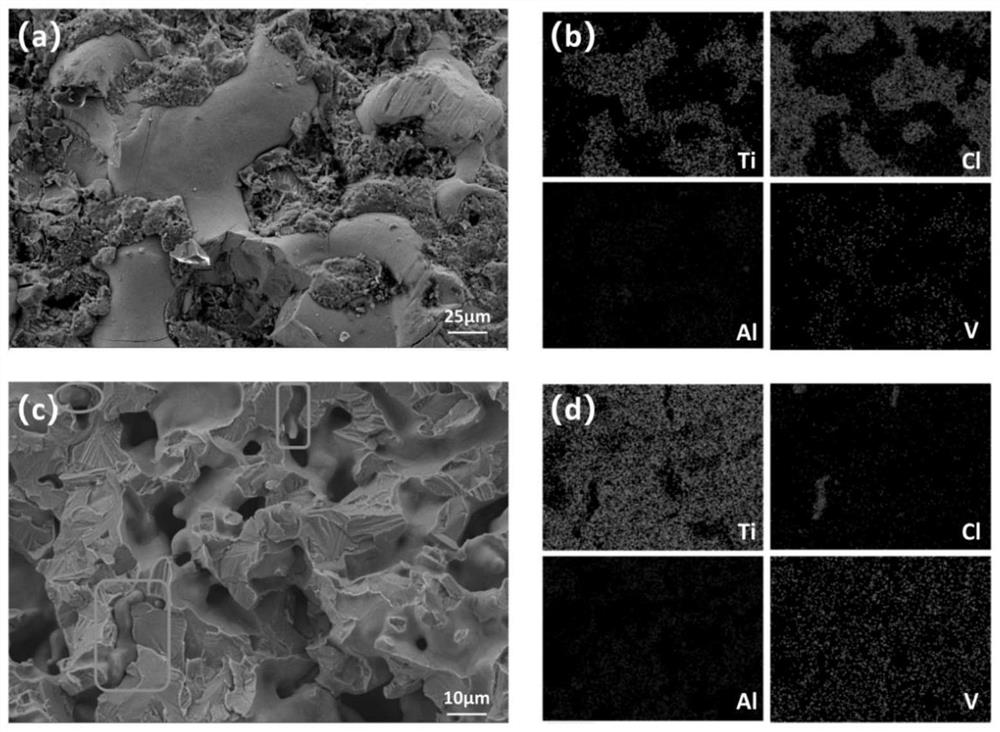

[0034] 1) Select the porous TC4 alloy with better comprehensive properties among the porous light metal alloys as the matrix material, and select ammonium chloride as its cooling medium.

[0035] 2) The porous TC4 alloy sample was prepared by vacuum sintering. The prepared sample was a disc with a diameter of 35 mm and a thickness of 6 mm, the sample mass was 16.13 g, and the open porosity was 20.2%.

[0036] 3), adopt the repeated negative pressure impregnation method to carry out the preparation of ammonium chloride filling porous TC4 alloy spontaneous perspiration composite material, and the specific preparation process is as follows: 8g of ammonium chloride is mixed with 20ml of deionized water, and stirred at room temperature for 30min to prepare into a supersaturated solution of ammonium chloride. The porous TC4 alloy sample was placed in ...

Embodiment 2

[0040] A preparation of ammonium salt filled porous metal spontaneous sweating composite material, comprising the following steps:

[0041] 1) Select the porous TC4 alloy with better comprehensive properties among the porous light metal alloys as the matrix material, and select ammonium chloride as its cooling medium.

[0042] 2) The porous TC4 alloy sample was prepared by vacuum sintering. The prepared sample was a disc with a diameter of 20 mm and a thickness of 6 mm. The sample mass was 6.44 g and the open porosity was 20.6%.

[0043] 3), adopt the recrystallization method to carry out the preparation of ammonium chloride filling porous TC4 alloy spontaneous perspiration composite material, and the specific preparation process is as follows: 30.1g of ammonium chloride and 50ml of deionized water are mixed in a suction filter bottle, and the temperature is 70 ° C. The solution was stirred for 1 h to prepare a saturated solution of ammonium chloride. The porous TC4 alloy sam...

Embodiment 3

[0045] A preparation of ammonium salt filled porous metal spontaneous sweating composite material, comprising the following steps:

[0046] 1) Select the porous TC4 alloy with better comprehensive properties among the porous light metal alloys as the matrix material, and select the mixed salt of two inorganic salts, ammonium chloride and ammonium bromide, as the cooling medium.

[0047] 2) The porous TC4 alloy sample was prepared by vacuum sintering. The prepared sample was a disc with a diameter of 40 mm and a thickness of 6 mm. The sample mass was 28.01 g and the open porosity was 19.8%.

[0048] 3), adopt the repeated negative pressure impregnation method to carry out the preparation of ammonium chloride / ammonium bromide mixed salt filling porous TC4 alloy spontaneous sweating composite material, and the concrete preparation process is: the ammonium chloride of 7.44g is mixed with the deionized water of 20ml, Stir at room temperature for 30 minutes to prepare a supersaturat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com