Screw extruder for door seal magnetic strip production

A screw extruder and magnetic strip technology, applied in dryers, lighting and heating equipment, drying, etc., can solve the problems of long time spent on mold replacement, facilitate cleaning, improve production efficiency, and save disassembly and assembly the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

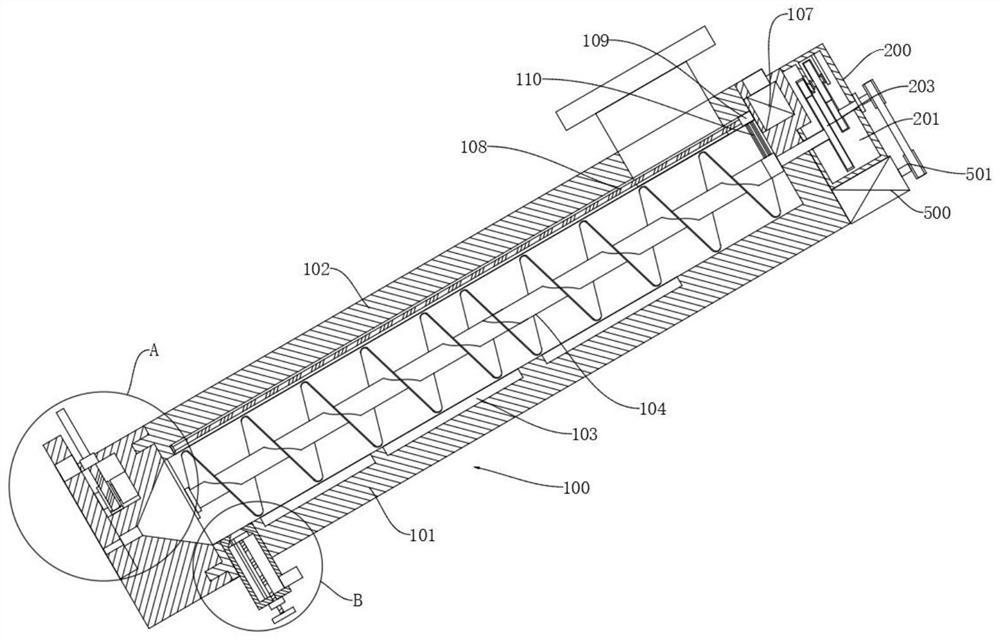

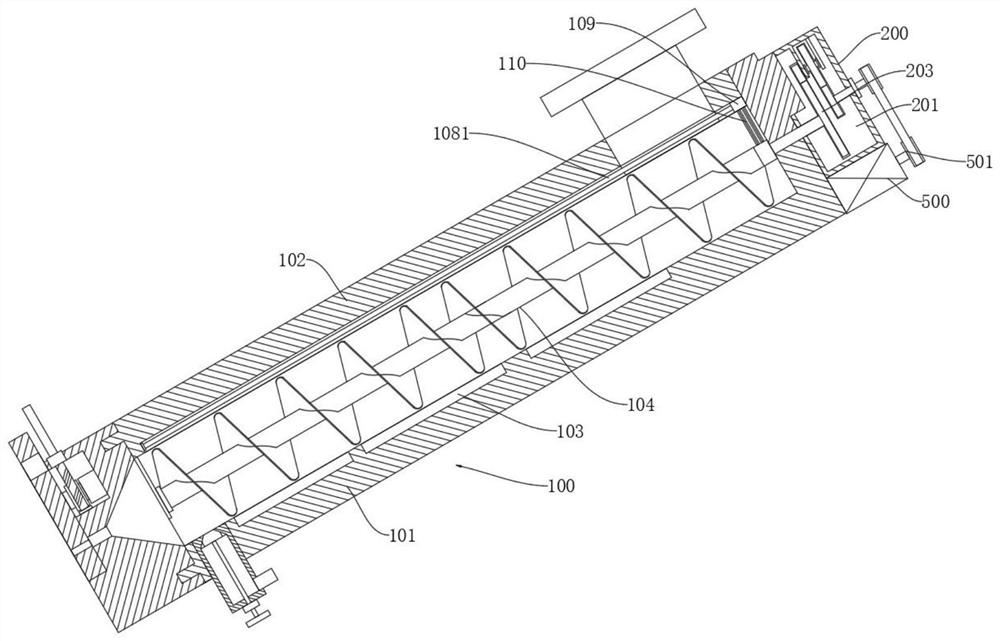

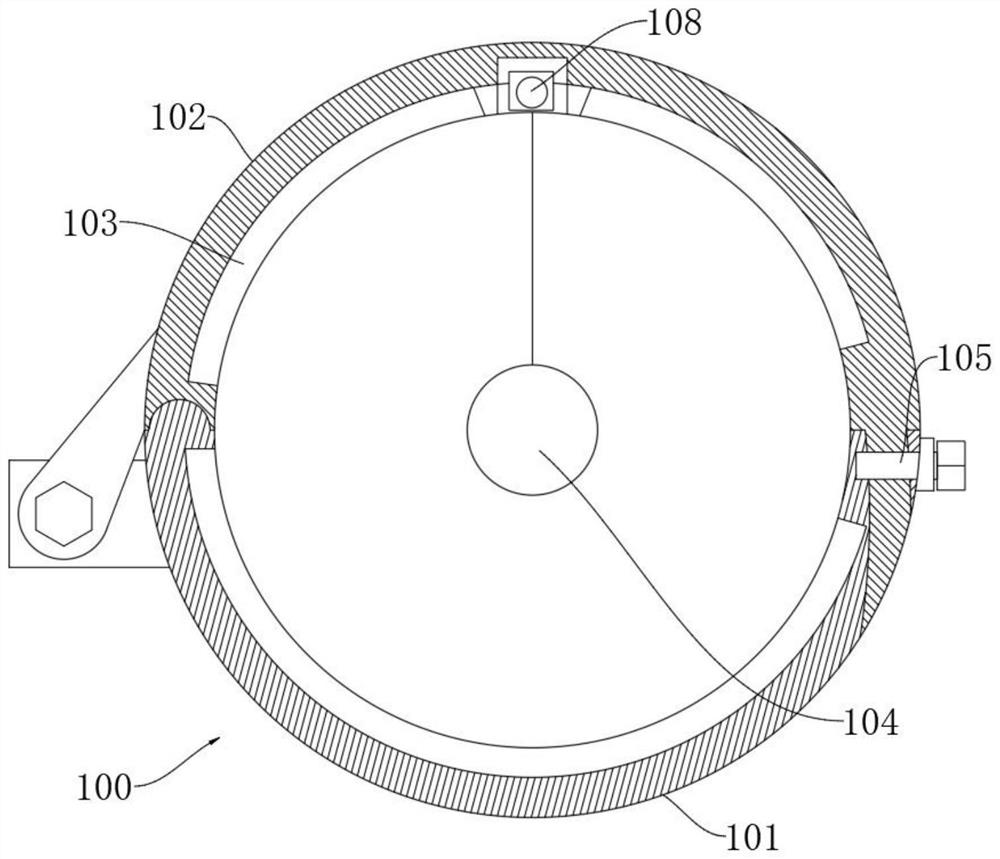

[0030] Example: refer to Figure 1-Figure 7 , a screw extruder for door seal magnetic strip production, including an installation pipe 100, and also includes: a screw rod 104 rotatably connected in the installation pipe 100; an electric heater 103 fixedly connected to the inner wall of the installation pipe 100; The installation box 200 is connected to the end of the installation pipe 100, and the output shaft of the installation box 200 is detachably connected to the screw rod 104; the installation box 200 is provided with a first installation cavity 201 and a second installation cavity 202, the first installation cavity 201 A speed change gear set 203 is arranged inside, and the two ends of the speed change gear set 203 are respectively fixedly connected to the output shaft and the input shaft of the installation box 200; fixedly connected to the suction pump 204 in the second installation cavity 202; fixedly connected to the second installation The shunt box 205 in the cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com