Preparation method of photopolymerization hydrogel

A hydrogel and photopolymerization technology, applied in the field of organic synthesis, can solve problems such as poor mechanical properties of hydrogels, and achieve the effects of low price, low energy consumption, and large reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0030] Embodiment 1: The preparation method of the photopolymerized hydrogel in this embodiment is as follows:

[0031] 1. Add 81 mL of acrylic acid, 84 mg of polyethylene glycol diacrylate and 4.2 g of ammonium persulfate to 300 mL of deionized water, stir to form a uniform solution, add 8.4 g of pectin, and stir with a magnetic stirrer at a speed of 600 rpm in the dark 12h-14h until the pectin dissolves to obtain a hydrogel base liquid;

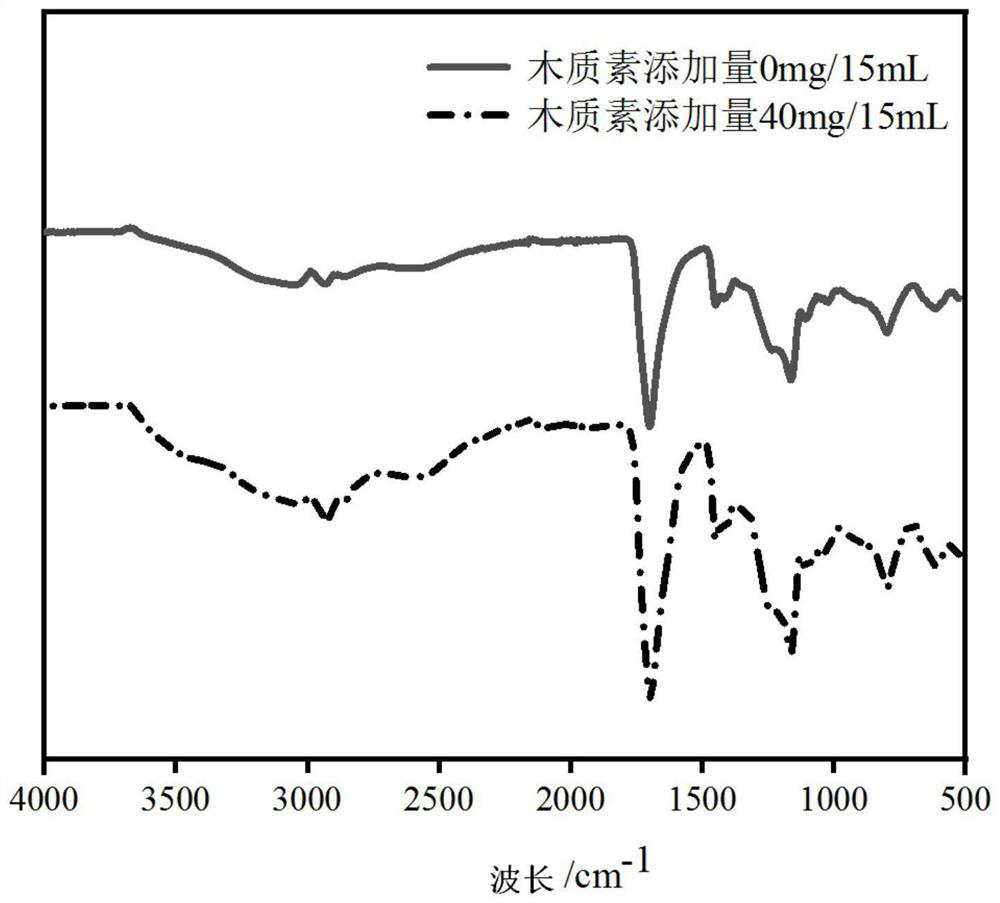

[0032] 2. Dissolve 10-50mg of alkali lignin in 0.3mL of sodium hydroxide solution with a concentration of 0.15g / L, ultrasonicate for 1min, add 15mL of hydrogel base solution, and then use a xenon light source at a light intensity of 150mv / cm 2 Under certain conditions, irradiate for 30-50 min, and illuminate until the solution forms a uniform and non-flowing colloid, that is, a photopolymerized hydrogel is obtained.

specific Embodiment approach 2

[0033] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the ultrasonic frequency in step 2 is 40 kHz. Others are the same as the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, 30 mg of alkali lignin is taken and dissolved in 0.3 mL of sodium hydroxide solution with a concentration of 0.15 g / L. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fracture energy | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com