Large radial load cylindrical roller bearing friction torque testing machine

A technology of cylindrical roller bearings and friction torque, applied in mechanical bearing testing, force/torque/power measuring instruments, instruments, etc., can solve the problem of increased friction force between the force transmission rope and the measuring ring, increased measurement error, and difficult to be true Reflect problems such as cylindrical roller bearing friction moment, to avoid unbalanced load moment and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

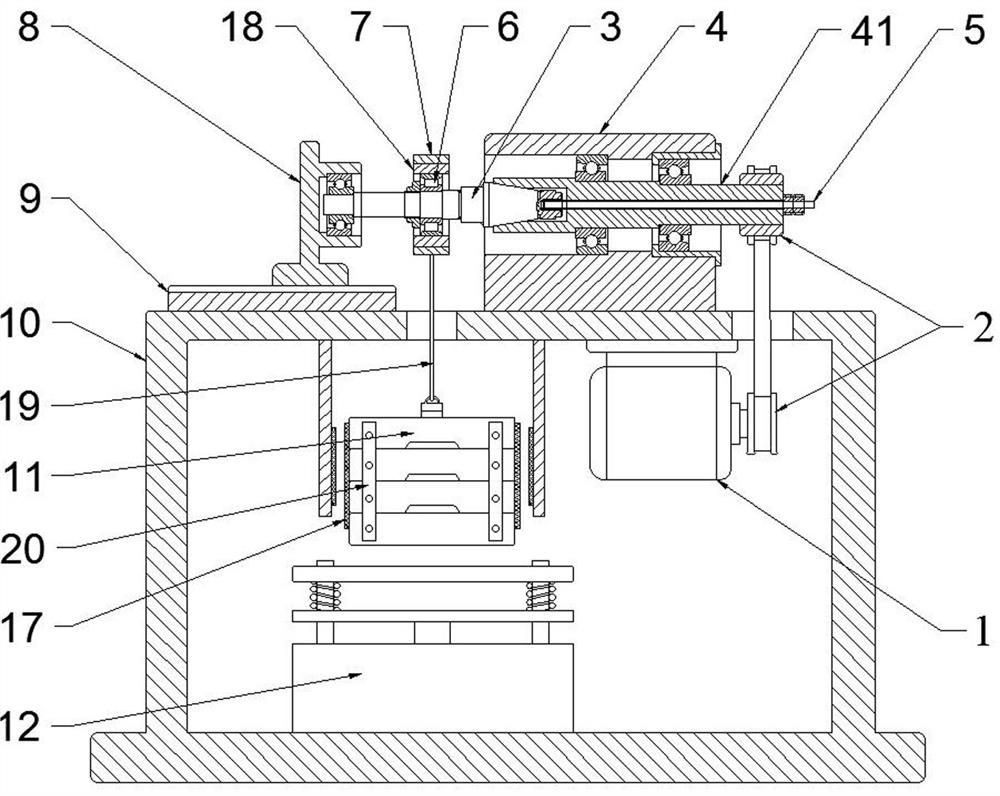

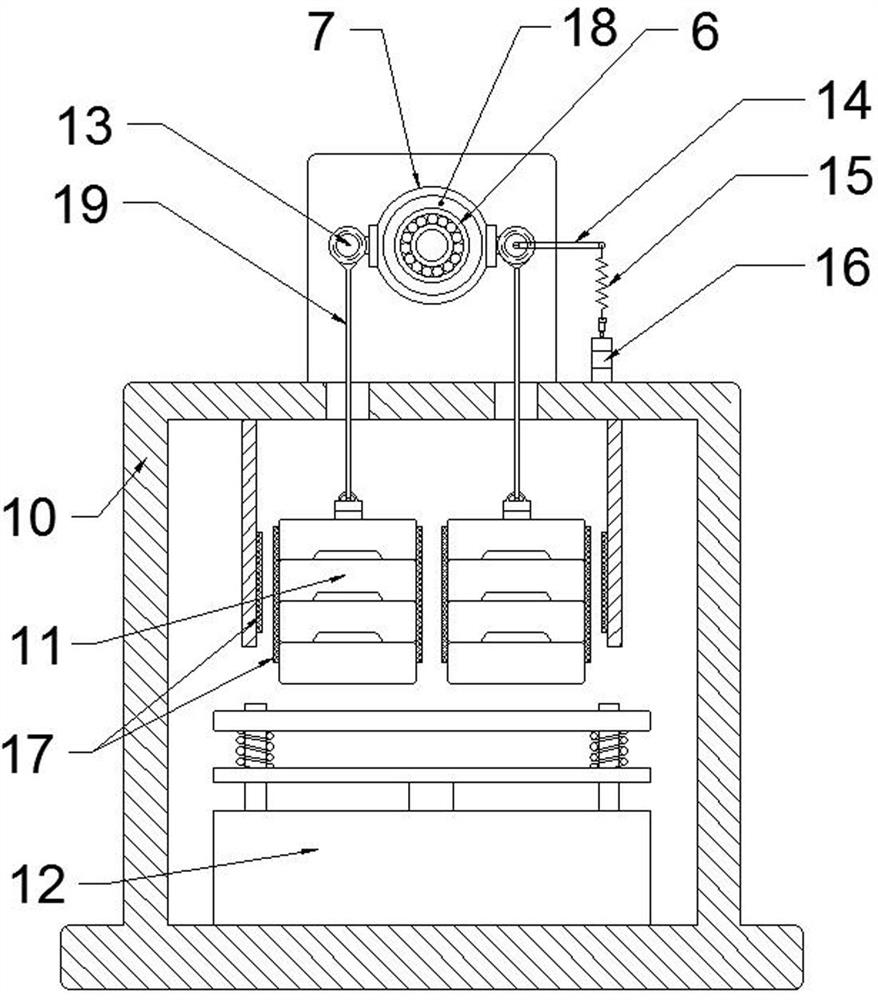

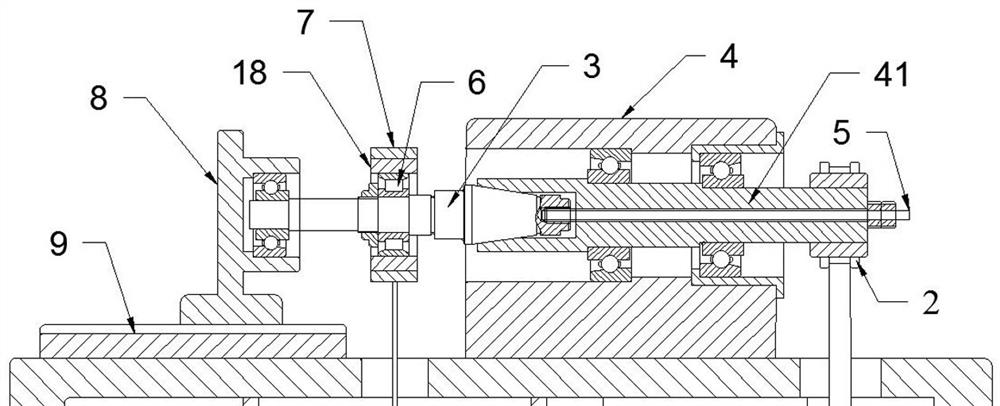

[0028] The large radial load cylindrical roller bearing friction torque tester of this embodiment can measure the friction torque of the cylindrical roller bearing under different rotational speed and load conditions, with high measurement accuracy, and the tested bearing 6 is easy to disassemble. The specific embodiments of the present invention will be further described in detail below with reference to the accompanying drawings. Left and right directions refer to figure 1 left and right directions shown in .

[0029] The testing machine is installed horizontally, the frame 10 is a cuboid as a whole, and the top surface of the frame 10 is fixed with a spindle box 4 and a sliding table 9 , and the support base 8 can be slid left and right on the sliding table 9. Inside the spindle box 4 Use ball bearings with high rotational accuracy to assemble the tie rod 5, the two ends of the mandrel 3 are respectively installed on the support seat 8 and the main shaft 41, the tested bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com