Three-phase separation system for fine separation

A three-phase separation and fine separation technology, applied in the field of fine separation three-phase separation system, can solve the problems of low separation accuracy, incomplete separation of oil and water phase, waste, etc., to improve separation effect, reduce oil phase residue, reduce oil wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following embodiments can make those skilled in the art understand the present invention more comprehensively, but do not limit the present invention to the scope of the described embodiments.

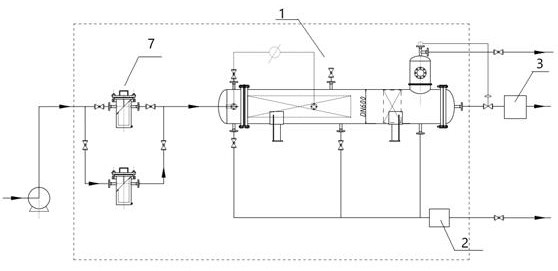

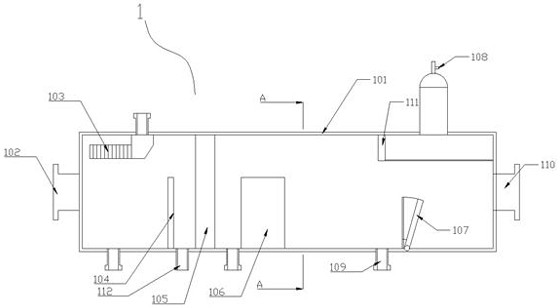

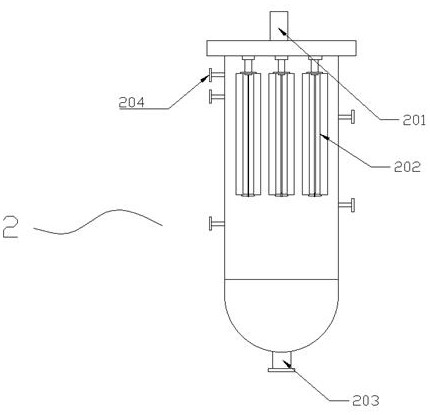

[0033] like Figure 1-9 As shown, the present invention provides a finely separated three-phase separation system, including a primary horizontal three-phase separator 1, a secondary vertical water phase separator 2, a secondary vertical oil phase separator 3, an oil-water interface identification Mechanism 4 and a controller for controlling the operation of the system.

[0034] The primary horizontal three-phase separator 1 includes a horizontally arranged square tank body 101, one side of the square tank body 101 is provided with a three-phase inlet 102, and a pre-filter is connected to the three-phase inlet 102 outside the primary horizontal three-phase separator 1 7, the square tank 101 is provided with an inlet distributor 103, a steady flow plate 104, a wave eliminato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com