Method for extracting urotropine from oxadiazine wastewater

A technology for urotropine and oxadiazine, which is applied in the field of extracting urotropine, can solve problems such as difficulty in separating ammonium sulfate and urotropine, and achieve the effect of accelerating dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

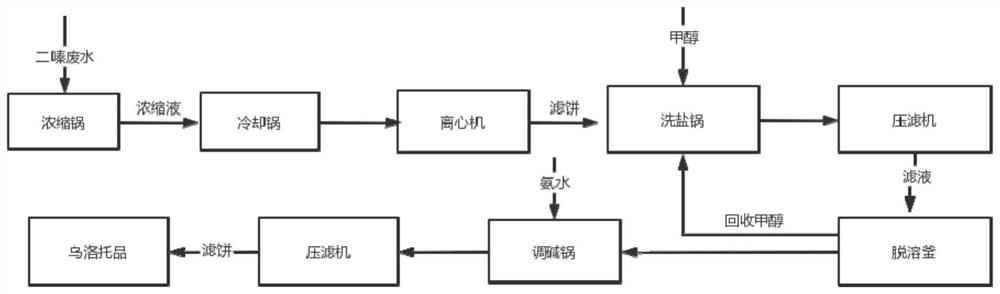

Method used

Image

Examples

Embodiment 1

[0042] Add 1000g of evil twozine wastewater to the single-mouth pear bottle for heating and decompression and dehydration. The negative pressure is -0.08 ~ -0.09MPa, and the dehydration temperature is 60 to 80 ℃. The water bath cools to 30 ° C, and then use ice water to cool down to 10 ° C.

[0043] Filter the lower salt pump to dry. The main ingredient of the filter cake is ammonium sulfate. The main components of the filter liquid are Ulot, ammonium sulfate, and water. Continue heating and decompression dehydration, adjust the negative pressure to -0.08 ~ -0.09MPa, dehydrate temperature of 60-90 ℃, until the moisture is basically removed, and the methanol is added, and the temperature is stirred at about 60 ° C for 1h.

[0044] Filter the ammonium sulfate in the methanol solution while it is hot. The ulot product is dissolved in methanol. The Ulotne methanol solution is added to the single-port pear-shaped bottle for heating and decompression of the methanol. MPA and methanol te...

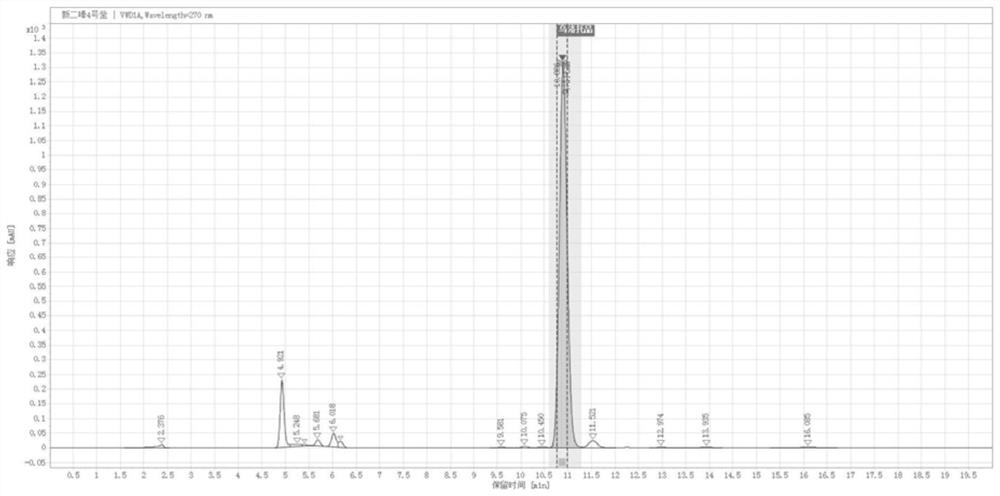

Embodiment 2

[0047] Add 2000g of evil twozine wastewater to the single-mouth pear-shaped bottle for heating and decompression and dehydration, adjust the negative pressure to -0.08 ~ -0.09MPa, dehydrate temperature of 60 to 80 ℃, until a large amount of salt stops from the water, and the precipted salt will be salt. Stir in the water bath to cool to 30 ° C, then use ice water to cool down to 10 ° C.

[0048] Filter the lower salt to dry to dry. The main ingredient of the filter cake is ammonium sulfate; the main component of the filter liquid is Ulot, ammonium sulfate, and water, and then add Ulot, ammonium sulfate, and water to a single -mouth pear -shaped bottle Continue heating and decompression dehydration, adjust the negative pressure to -0.08 ~ -0.09MPa, dewater temperature of 60-90 ℃, until the water is basically removed, 600g of methanol, and the temperature is stirred at about 60 ° C for 1h.

[0049] Filter the ammonium sulfate in the methanol solution while it is hot. The ulot produc...

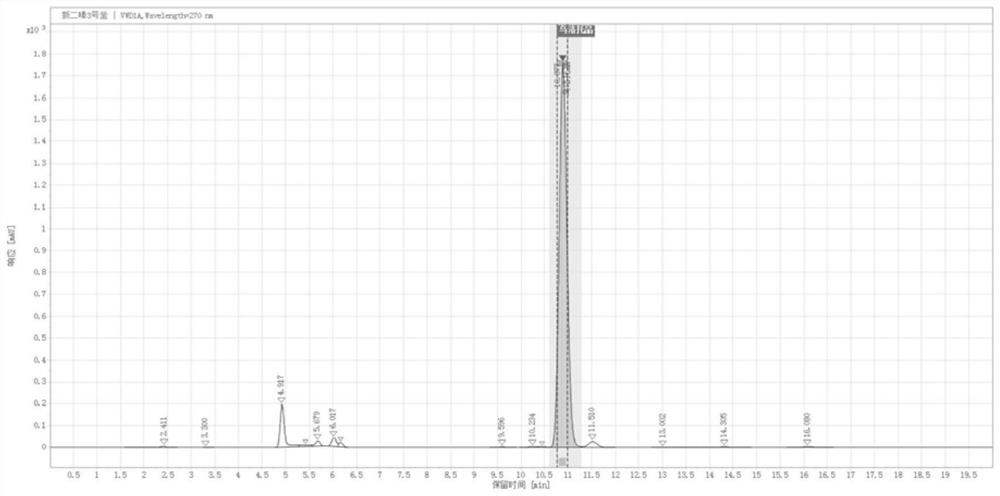

Embodiment 3

[0052] Add 3000g of wicked azine wastewater to the single-mouth pear-shaped bottle for heating and decompression dehydration, adjust the negative pressure to -0.08 ~ -0.09MPa, dewater temperature of 60 to 80 ℃ until a large amount of salt stops from the water, and the precipted salt will be salt. Stir in the water bath to cool to 30 ° C, then use ice water to cool down to 10 ° C.

[0053] Filter the lower temperature material to dry. The main component of the filter cake is ammonium sulfate. The main components of the filter liquid are Ulot, ammonium sulfate, and water. Heating and decompression dehydration, adjustment of negative pressure -0.08 ~ -0.09MPa, dehydration temperature of 60-90 ℃, until the water is basically removed, and 900g of methanol is added to keep the temperature stir at about 60 ° C for 1h.

[0054] Filter the ammonium sulfate in the methanol solution while it is hot. The ulot product is dissolved in methanol. The Ulotne methanol solution is added to the singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com