Method for removing trace phenyl trichloride in methyl phenyl dichlorosilane

A technology of methylphenyldichlorosilane and phenyltrichloride, which is applied in the direction of chemical instruments and methods, silicon organic compounds, compounds of group 4/14 elements of the periodic table, etc., can solve problems such as secondary pollution, and achieve The effect of reducing the generation of waste liquid, easy realization, and overall energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

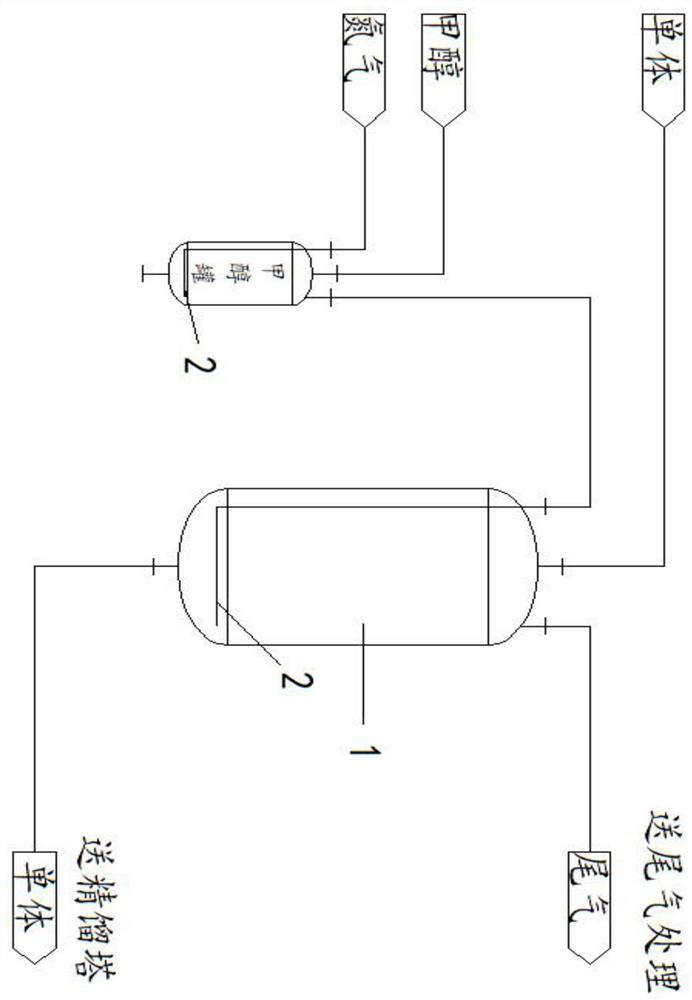

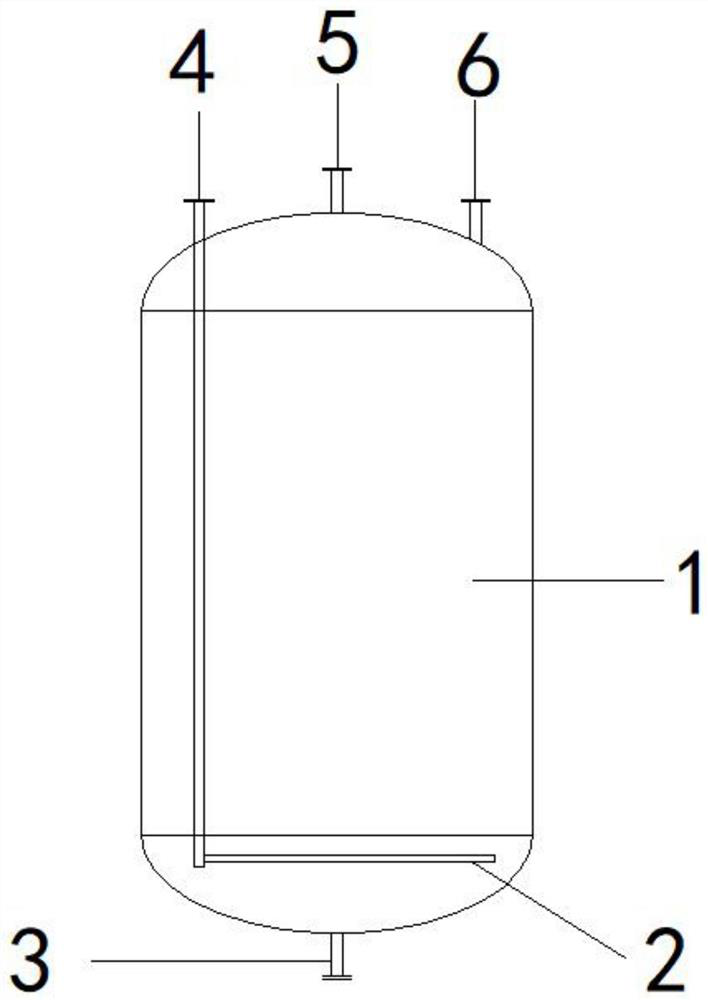

Image

Examples

Embodiment 1

[0034] Add 1KG of 98% methylphenyldichlorosilane to a 2000ml three-necked flask, insert a glass capillary, connect the capillary to the conical flask, open two holes in the flask stopper, insert a glass tube, and add an appropriate amount to the conical flask. Methanol, insert the gas inlet glass tube below the liquid level, turn on nitrogen gas, pass nitrogen gas into the three-necked flask, and discharge the tail gas after washing with water. Timing 2 hours. After weighing, methanol was reduced by 2.2 g. Through simple rectification in a laboratory glass rectification tower, 900 g of methylphenyldichlorosilane was obtained, and the purity was 99.2% through gas chromatography analysis. The calculated yield was 90%.

Embodiment 2-4

[0036] In embodiment 2-4, except changing nitrogen feeding time, operate in the same way as embodiment 1, and specific process conditions and relative product yield are shown in the following table:

[0037] serial number Nitrogen passing time Distillation product purity yield 1 (Example 2) Pass nitrogen for 3 hours 99.4% 93% 2 (Example 2) Passing nitrogen gas for 4 hours 99.5% 95% 3 (Example 2) Pass nitrogen for 5 hours 99.5% 90%

Embodiment 5

[0039] Add 1KG of 98% methylphenyldichlorosilane to a 2000ml three-necked flask, insert a glass capillary, connect the capillary to the conical flask, open two holes in the flask stopper, insert a glass tube, and add an appropriate amount to the conical flask. pure water, insert the gas inlet glass tube below the liquid level, turn on nitrogen gas, pass nitrogen gas into the three-necked flask, and discharge the exhaust gas after washing with water. Timing 2 hours. After weighing, pure water was reduced by 1.8g. Through simple rectification in a laboratory glass rectifying tower, 910 g of methylphenyldichlorosilane was obtained, and the purity was 99.0% by gas chromatography analysis. The calculated yield was 91%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com