Disc holder for disc player

A technology for a clamping device and a player, which is applied in the direction of instruments, recording information storage, etc., can solve the problems of the disc leaving the clamping device, the difficulty in setting the clamping force, and the increase in the clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

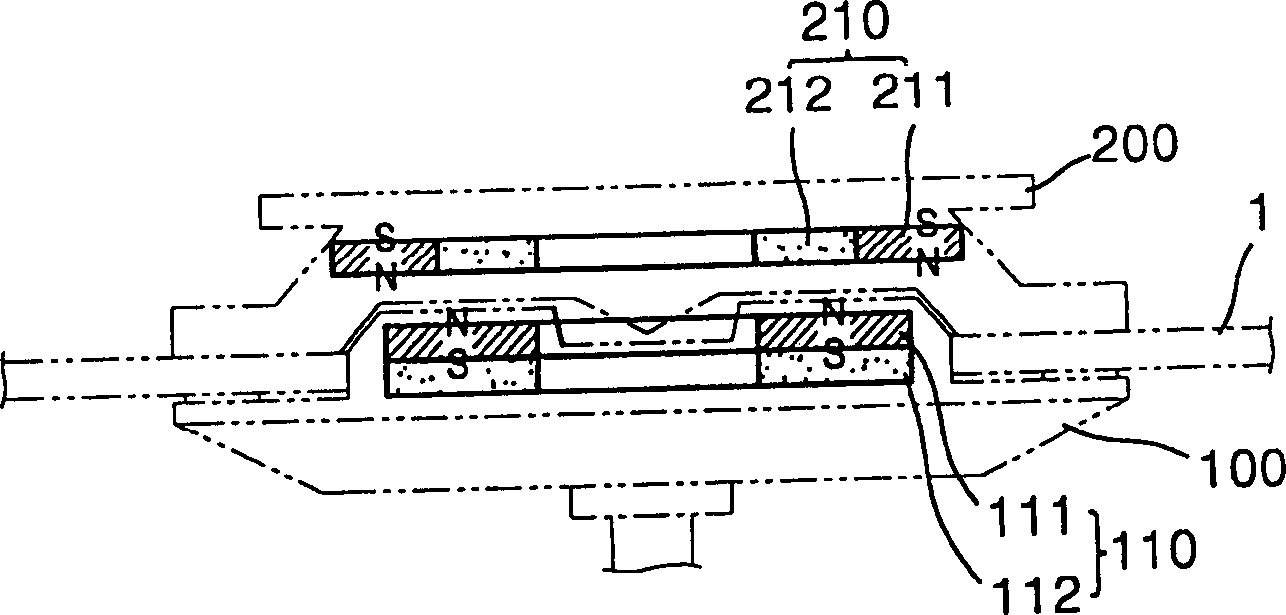

[0017] image 3 Shown is a disc holding device according to a first embodiment of the present invention. refer to image 3 , the disc clamping device includes: a turntable 100 for placing the disc 1 , a disc clamper 200 , a first magnet 110 , and a second magnet 210 . The holder 200 is opposite to the turntable 100 and holds the disc 1 placed in the turntable 100 . The first magnet 110 and the second magnet 210 are installed in the turntable 100 and the clamper 200 respectively, and provide clamping force generated by magnetic force.

[0018] The first magnet 110 includes a first magnet 111 and a first yoke 112 . The first yoke 112 is installed on the bottom surface of the first magnet 111 .

[0019] The second magnet 210 includes a second magnet 211 and a second yoke 212 . The second yoke 212 is positioned opposite the inner annular region of the first magnet 111 . A magnetic attractive force acts between the first magnet 111 and the second yoke 212 . The second magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com