Dual sectional mould

A segmented, molded technology for home appliances, home components, and other home appliances that can solve unwanted, extra time cost and handling, unsightly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

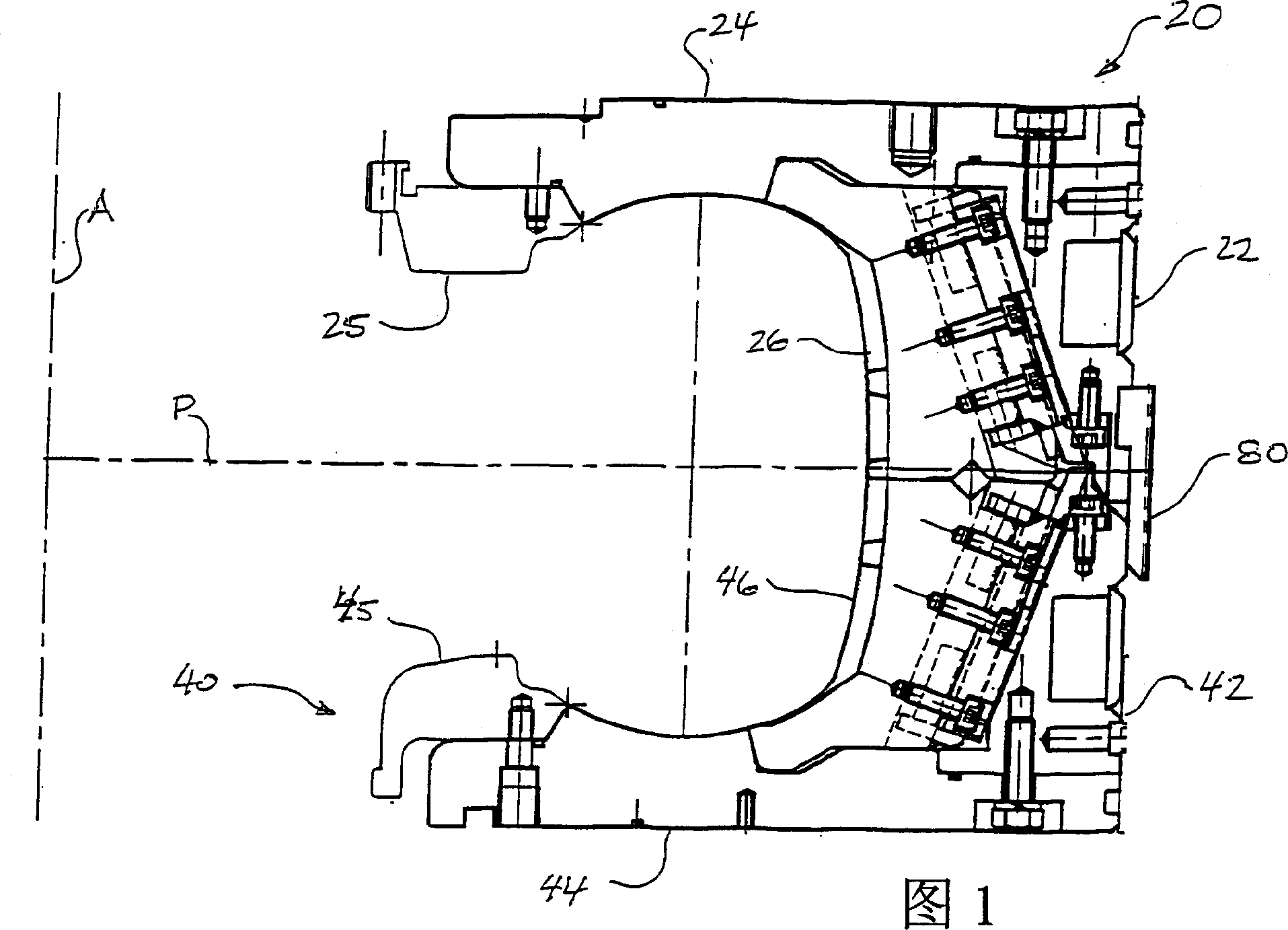

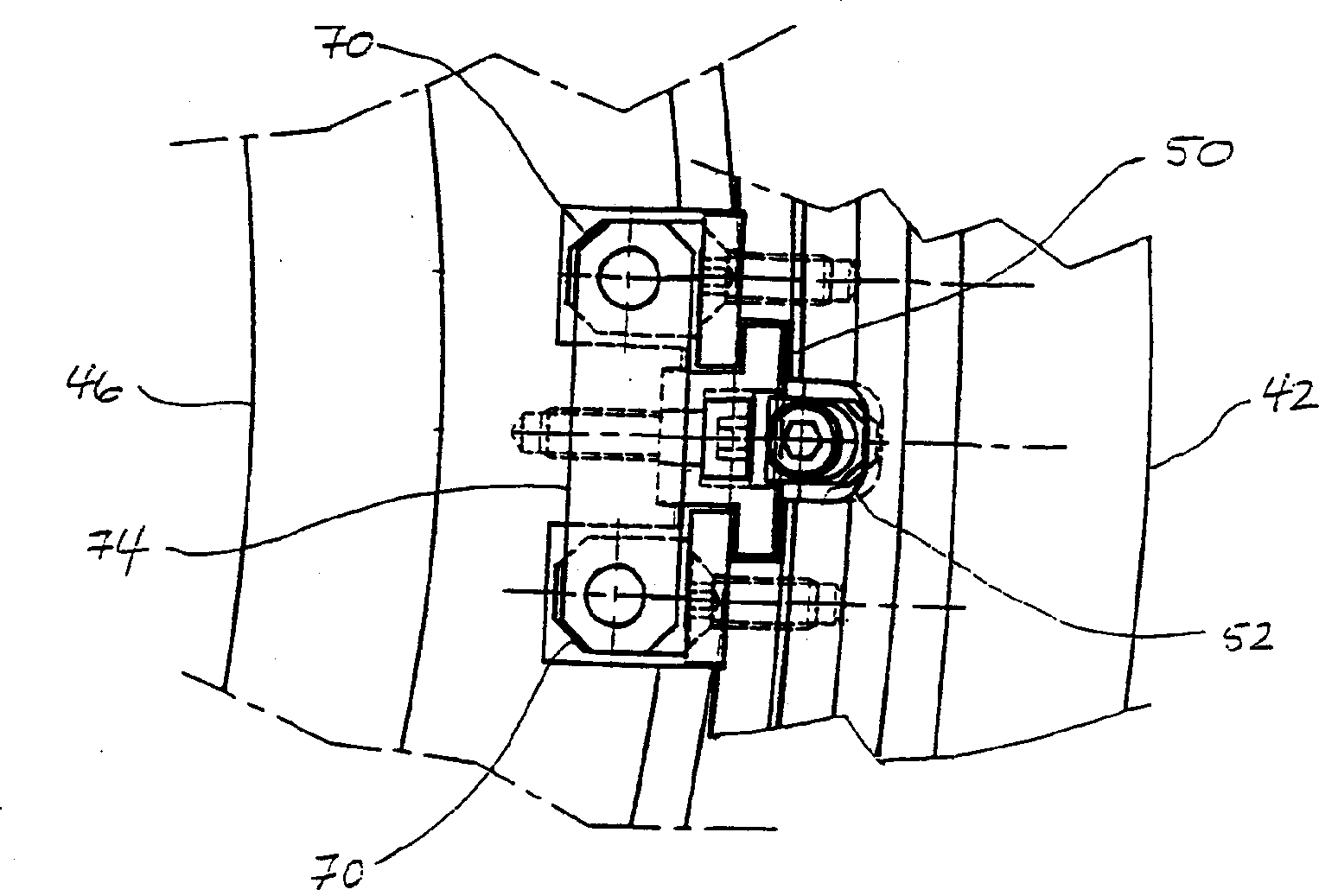

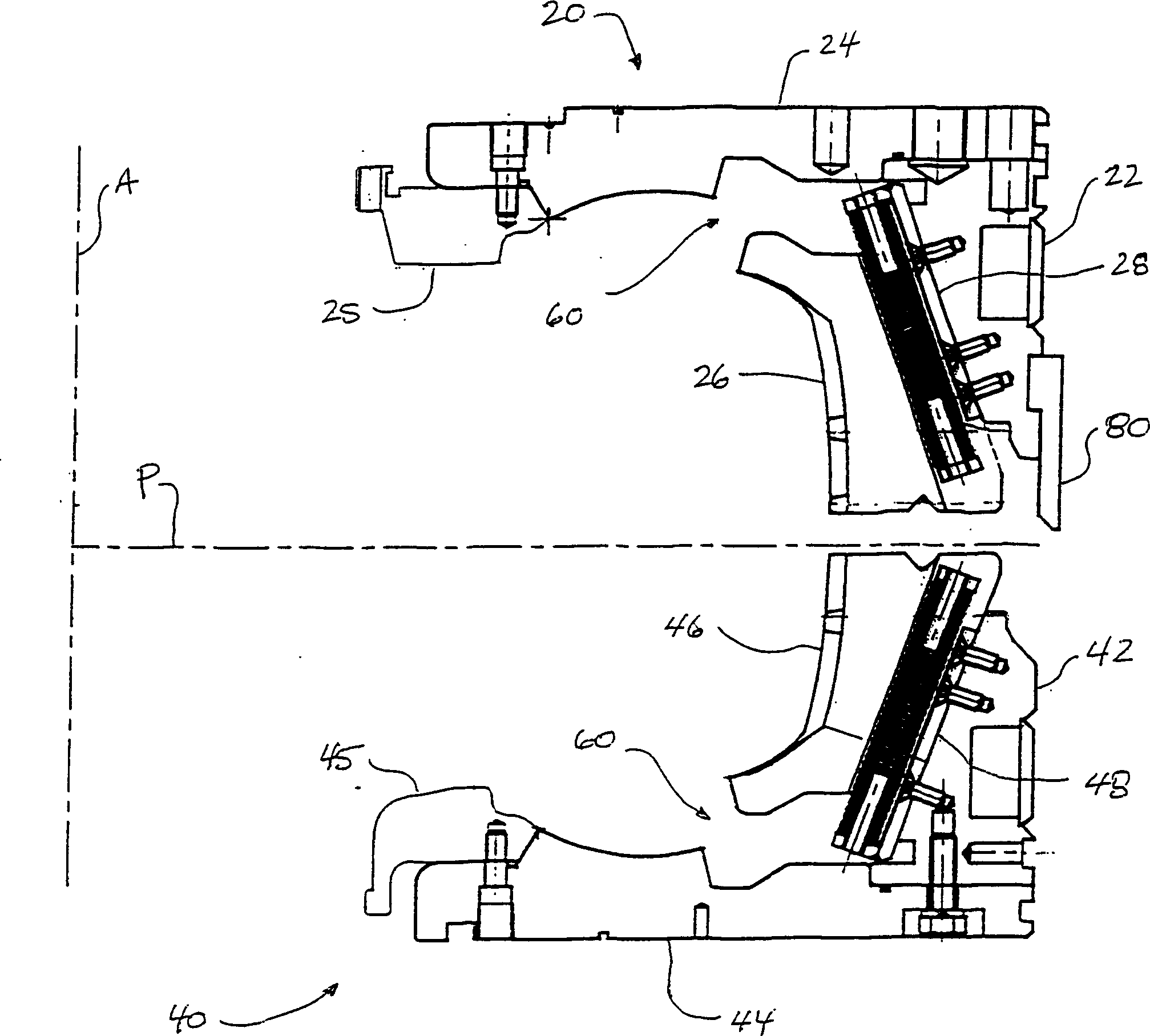

[0023] An improved two-piece segmented mold is shown in cross-section in the closed position in Figure 1, at figure 2 in the open position. Figure 1 and figure 2 The right side of the mold is shown, it being understood that the left side is a mirror image with respect to the subject of the present invention. The section of Fig. 1 is along a guiding mechanism, and figure 2 Via a spring mechanism, they are further described below. A mold axial centerline A and a parting line P are marked with dotted lines.

[0024] The mold has an upper shell 20 and a lower shell 40 which move relative to each other in a vertical direction (parallel to the axis A) and separate at the parting line P for loading and unloading the tyre. The upper shell 20 includes an annular upper mold base 22 that supports the other mold components, an upper side plate 24 that molds the sidewall of the tire, and a plurality of tread mold segments movably mounted on the upper mold base 22 26. A bead holder 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com