Antijamming signal transferring cable and high-speed high-amplitude pulse current sensor

A current sensor, high-amplitude pulse technology, applied in the direction of measuring current/voltage, cables with double-stranded/quad-stranded, instruments, etc., can solve the problem of no Hall current sensor, no measurement As a result, magnetic shielding cannot be achieved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

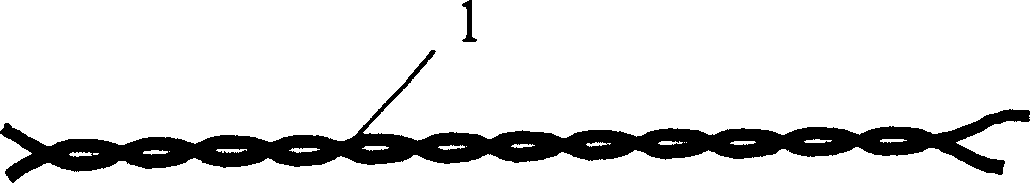

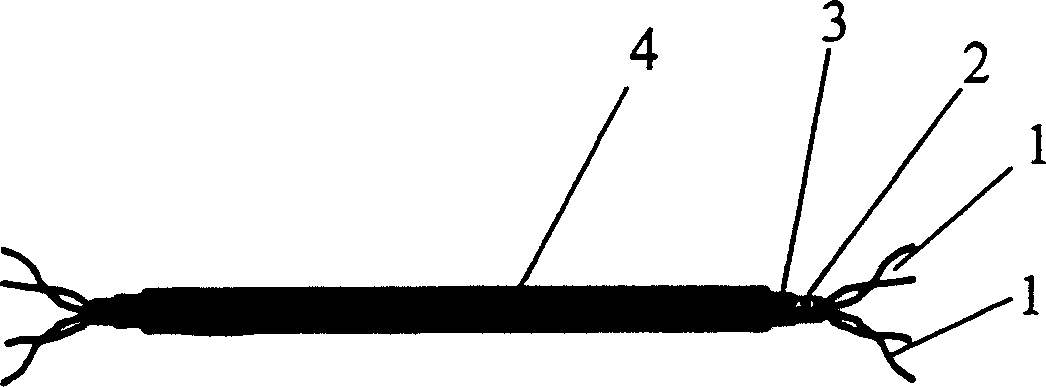

[0056] The structure of the high anti-jamming signal transmission cable in this embodiment is as follows: figure 1 , figure 2 As shown, the enamelled twisted pair 1 is formed by two enameled wires with a diameter of 0.12 mm twisted evenly and tightly. 4. Cover in turn two sets of enamelled twisted pairs that are independent of each other and placed in a free bend.

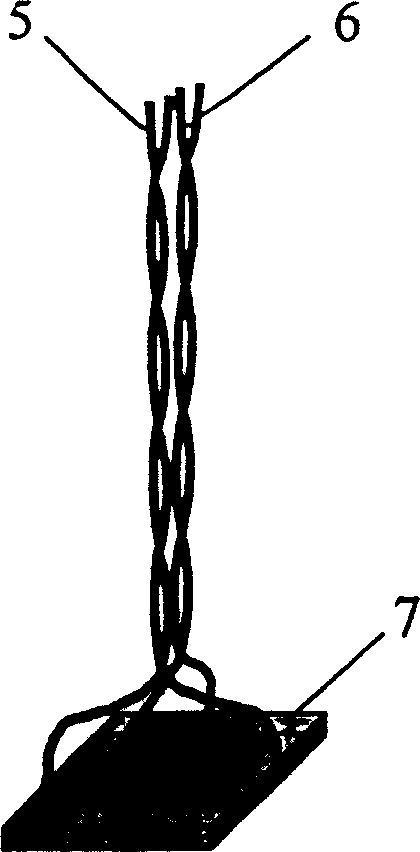

[0057] according to image 3 As shown, the two signal electrodes of the Hall chip 7 are directly welded to the ends of the two signal leads formed after the signal transmission line 5 of the high anti-interference signal transmission cable is bifurcated, and the two power supply electrodes are directly connected to the power supply of the high anti-interference signal transmission cable. The ends of the two power lead wires formed after the transmission line 6 is bifurcated are welded, and the "cross-section centers" of the two signal lead wires are symmetrically distributed in such as Image 6 The two sides o...

Embodiment 2

[0064] The structure of the high anti-interference signal transmission cable in the present embodiment is the same as that of Embodiment 1, as figure 1 , figure 2 shown. In this embodiment, a 0.2mm enameled wire is used to make an enameled twisted pair. The structure of the high-speed high-amplitude pulse current sensor is as follows: Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14, Figure 15 , Figure 16 As shown, it includes a printed board 21 , a Hall chip 7 , a high anti-interference signal transmission cable, a shield 19 , a conductor segment 26 , a substrate 24 and a housing 27 . There are two sets of printed lines 22 and 23 on the printed board 21, which are the pins connecting the Hall chip signal electrodes and the power electrodes. And close to the electrode arrangement on the corresponding Hall chip, such as Figure 11 As shown; the signal leads and power leads formed after the two sets of transmission lines of the high anti-interference si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com