Buttonhole machine and its method of forming eyelet stitch

A buttonhole machine and stitching technology, which is applied to floral stitch sewing machines, program-controlled sewing machines, textiles and papermaking, etc., can solve the problems of increased workload, easy infiltration of buttonhole stitches, and poor appearance decoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

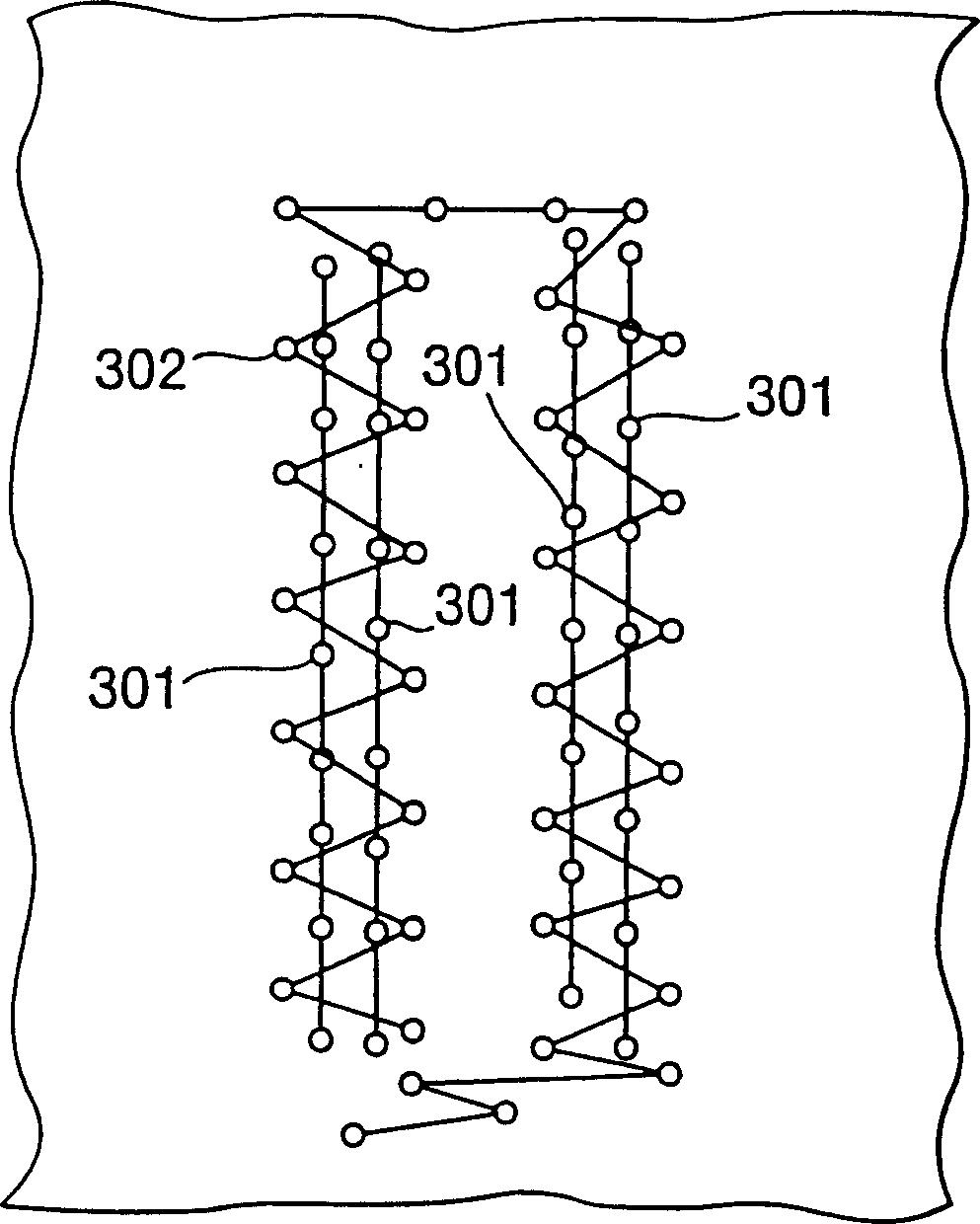

[0057] The embodiment of the present invention is an example of a so-called buttonhole machine for making button holes to which the present invention is applied, for example, forming on a processed cloth Figure 15 At the same time as the rectangular buttonhole stitch as shown, a button hole 80 is formed inside the buttonhole stitch 70. However, with figure 2 The description is based on the front and left of the. In addition, the following references to keyhole stitches and buttonholes Figure 15 The middle keyhole stitch 70 and button hole 80 are marked.

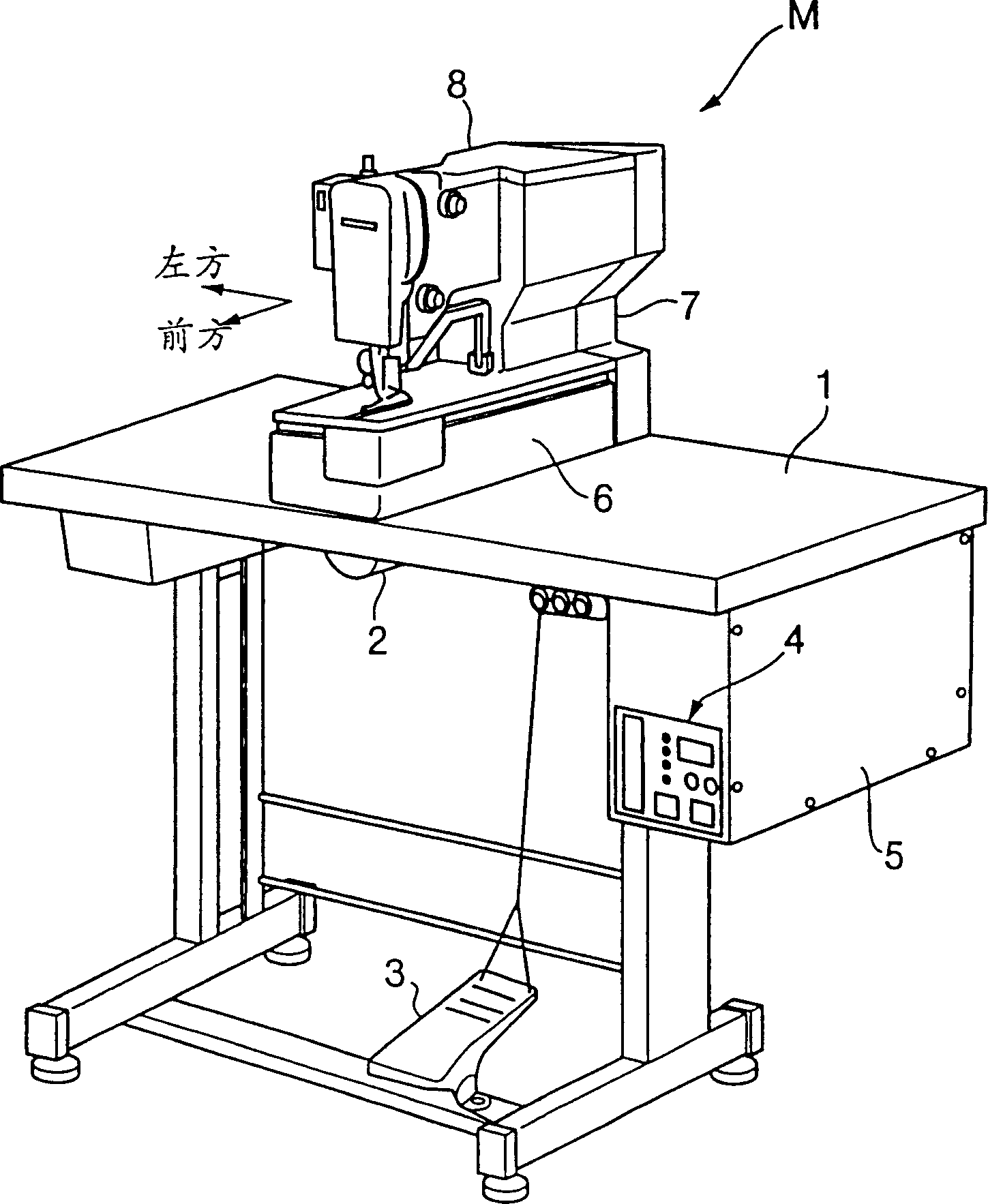

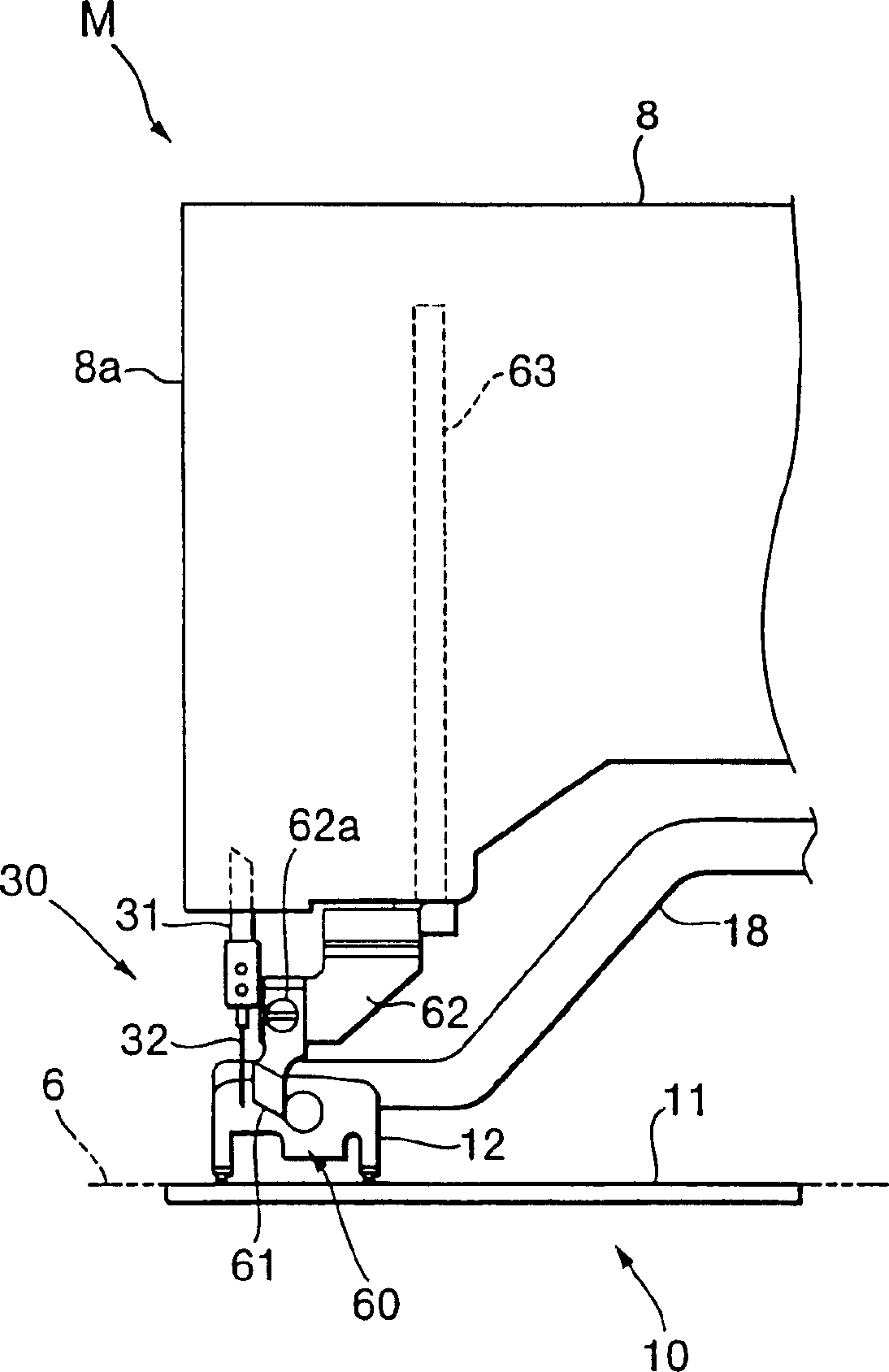

[0058] Such as figure 2 As shown, in the buttonhole machine M, the sewing machine table 1 is provided with a sewing machine motor 2, a pedal 3 for starting and stopping each driving part (detailed later) with the motor 2, and a pair of a predetermined buttonhole needle The operation panel 4 for setting and inputting a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com