Electrolytic cell for production of aluminium and method for maintaining crust on sidewall and recovering electricity

A technology of electrolytic cell and hard shell layer, applied in the field of electrolytic cell, to achieve the effects of good efficiency, increased fluoride content, and increased average lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

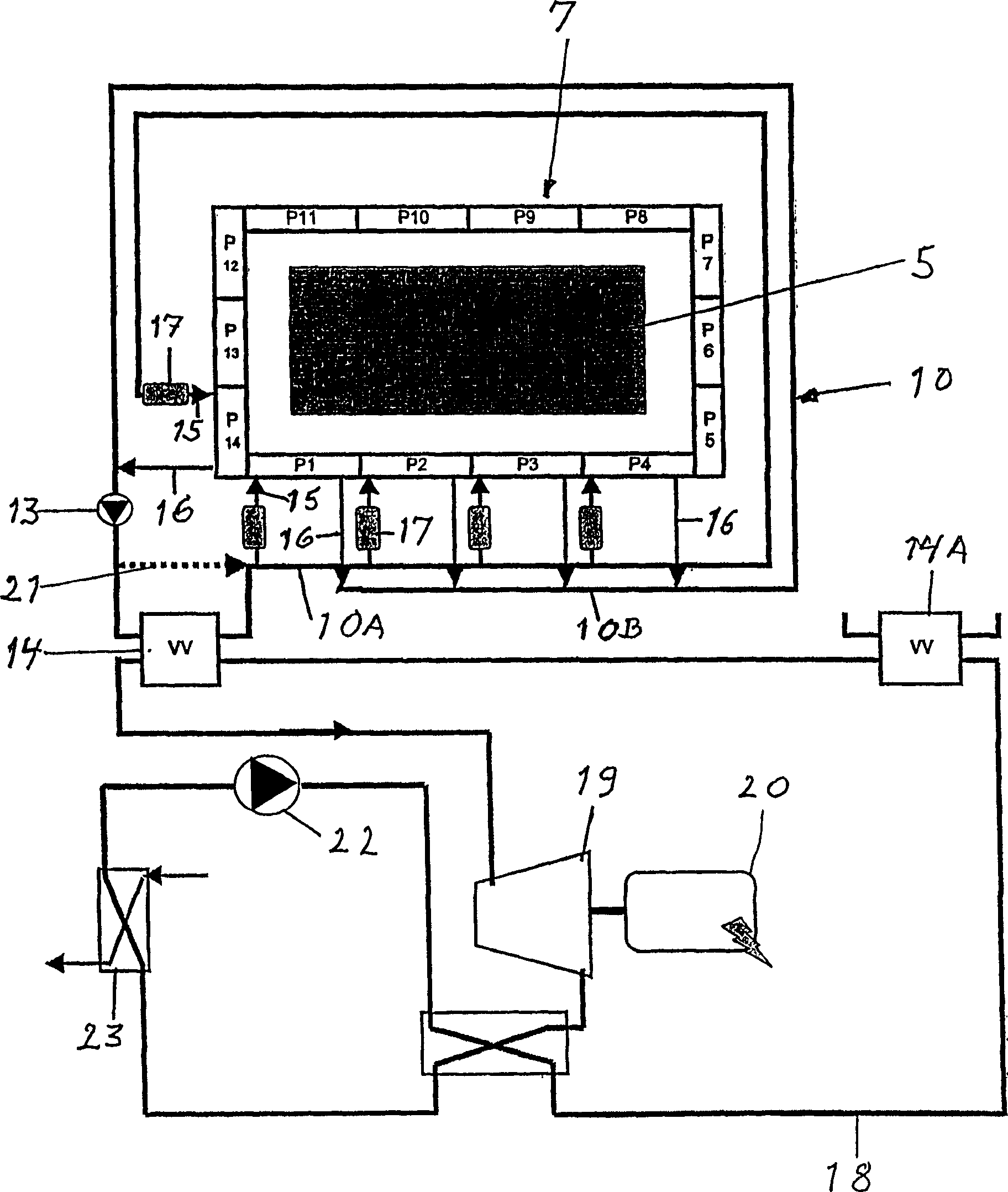

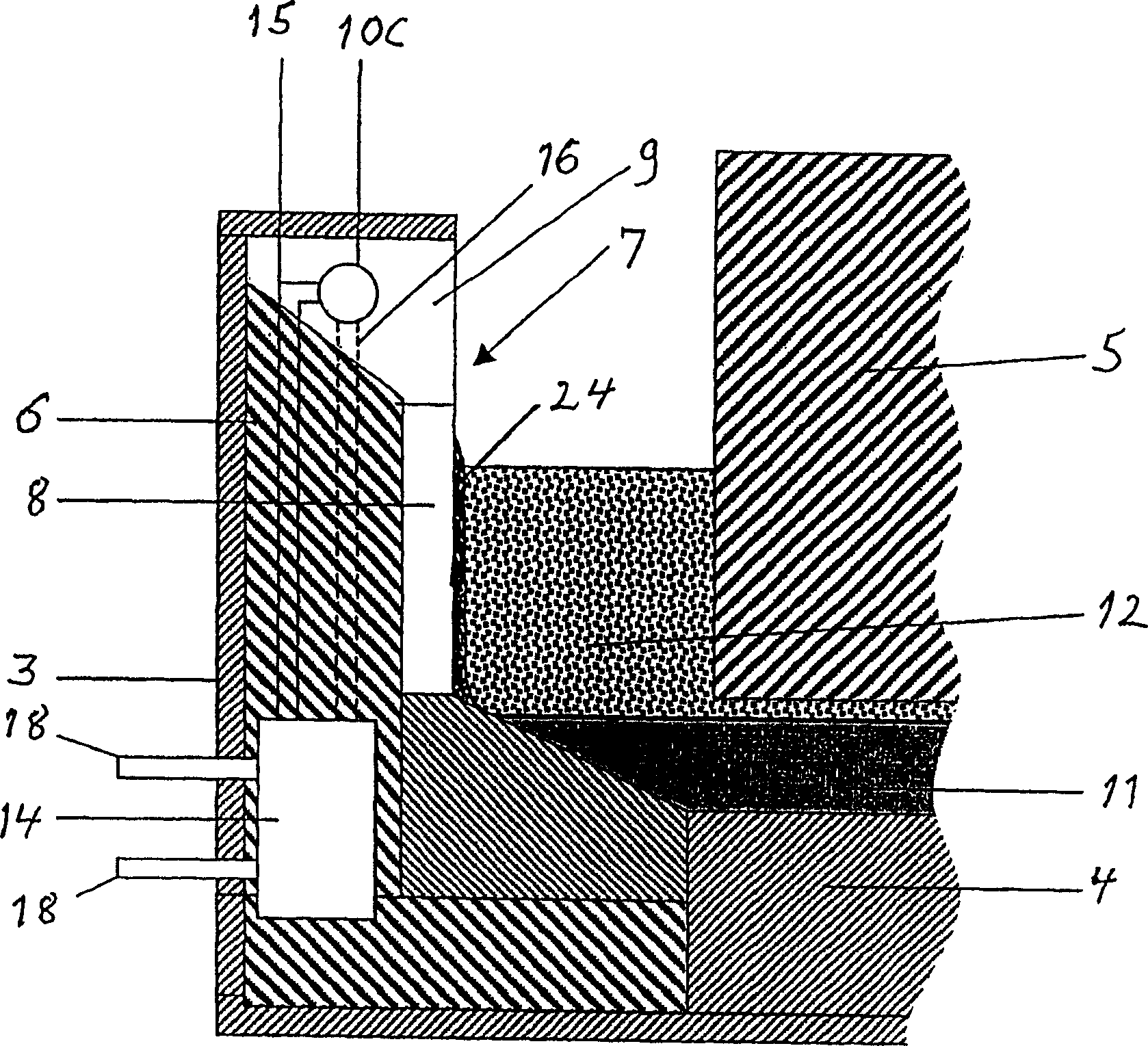

[0037] exist figure 1 The electrolytic cell used for the production of aluminium is shown in . The electrolytic cell comprises an electrolytic cell 2 with an outer casing 3 made of steel. In the bottom of the steel casing 3 is arranged a carbon block 4 connected to electrical terminals (not shown), which carbon block constitutes the cathode of the electrolytic cell. The anode 5 is arranged above and spaced apart from the carbon block 4 . The anode 5 is preferably a pre-baked carbon anode block or a self-baked carbon anode, also known as a Soderbergh self-baking anode. Anodes 5 cantilever from above and are connected to electrical terminals in a conventional manner (not shown).

[0038] Inside the steel casing 3, a layer of insulating refractory material 6 is arranged on the side walls of the electrolytic cell, and on the inside of this layer of insulating refractory material 6, an evaporative cooling plate 7 facing the inside of the electrolytic cell is arranged. The evapo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com