Ammonium and rare earth ion mixed exchange method of molecular sieve

A rare earth ion and ion exchange technology, which is applied in the field of ion exchange of molecular sieves, can solve the problems of sodium molecular sieve exchange, and achieve the effect of uniform rare earth content, high efficiency and high degree of automation of exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

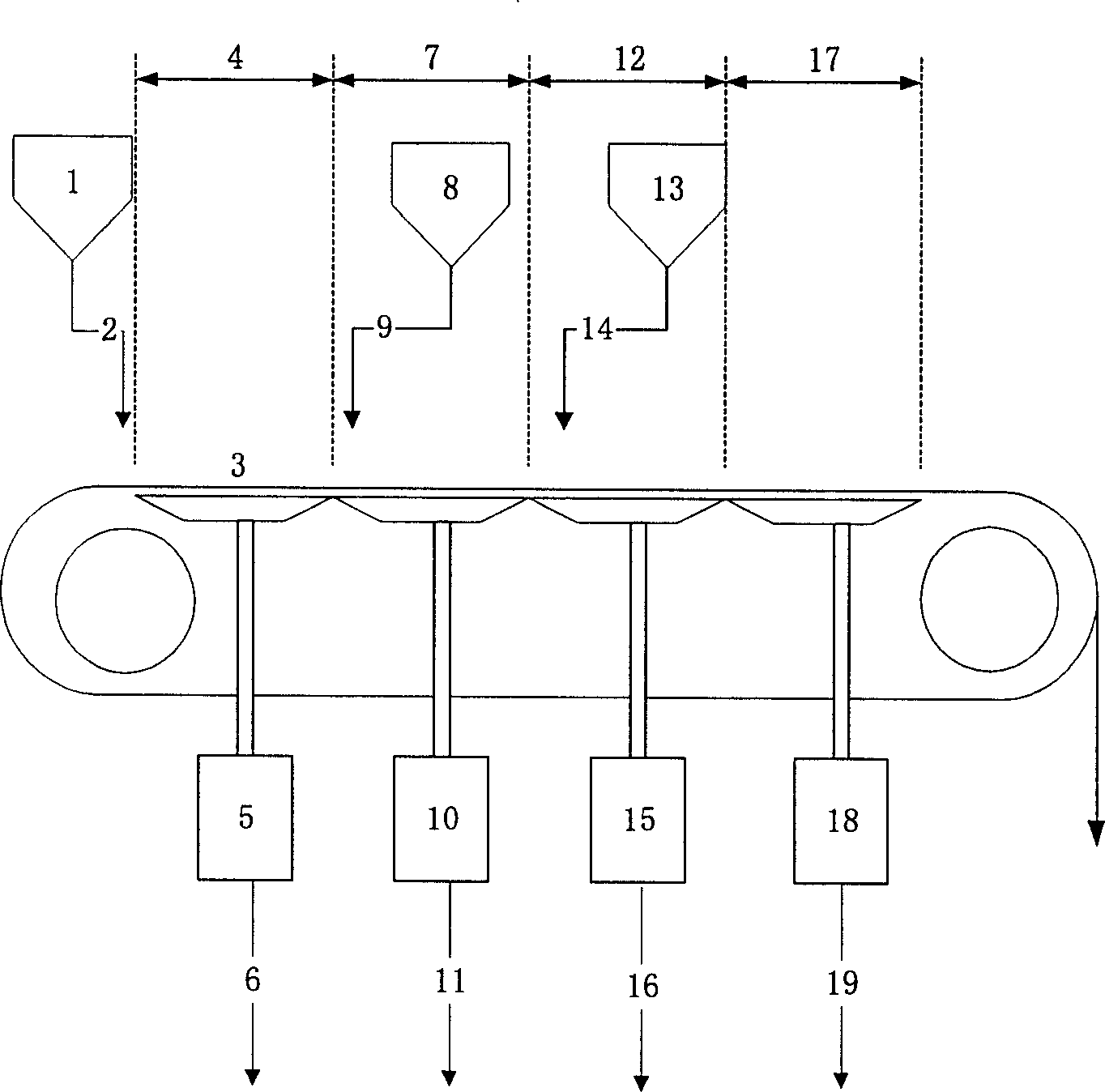

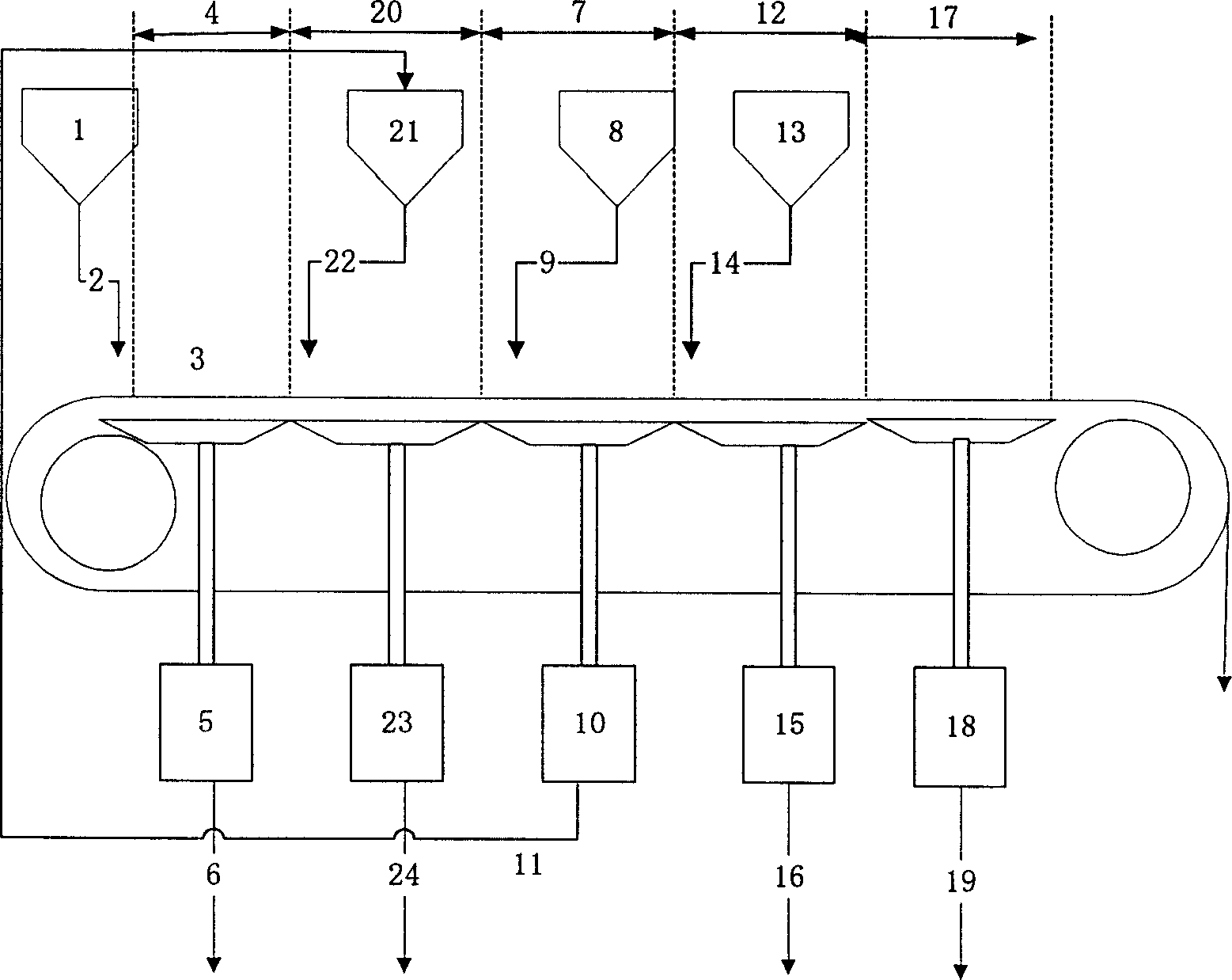

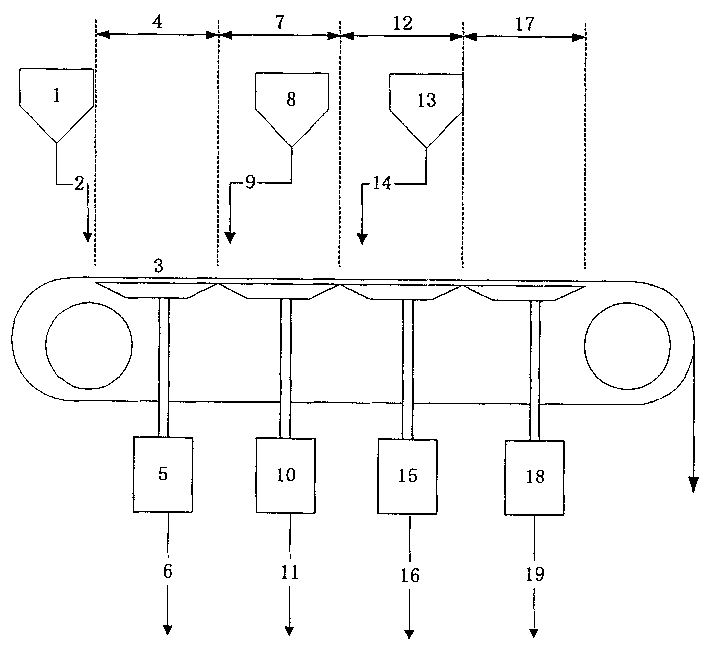

Method used

Image

Examples

example 1

[0071] This example uses a Buchner funnel as a separation device to simulate an industrial device to illustrate the method provided by the present invention.

[0072] Since the cloth funnel filtration device also undergoes stages such as filter cake formation, ion exchange (or countercurrent exchange before ion exchange), washing and drying, but these steps are carried out separately, it is continuously carried out with the belt filter. process is equivalent.

[0073] 1. Formation of filter cake.

[0074] The NaY zeolite (sodium oxide content is 14.3% by weight, unit cell constant is 24.66 angstroms, produced by Qilu Petrochemical Company Catalyst Factory) is mixed with deionized water to prepare a slurry with a solid content of 100 g / L, and the obtained slurry is stirred. Heated to 80°C under lower temperature, poured into a Buchner funnel, and at the same time, evacuated the filter bottle of the Buchner funnel to 0.05 MPa. Under the action of vacuum, a layer of filter cake...

example 2

[0085] This example uses a Buchner funnel as a separation device to simulate an industrial device to illustrate the method provided by the present invention.

[0086] 1. Formation of filter cake

[0087] The NaY zeolite (sodium oxide content is 13.8% by weight, unit cell constant is 24.65 angstroms, produced by Qilu Petrochemical Company Catalyst Factory) is mixed with deionized water to prepare a slurry with a solid content of 150 g / L, and the obtained slurry is stirred. Heated to 80°C under lower temperature, poured into a Buchner funnel, and at the same time, evacuated the filter bottle of the Buchner funnel to 0.04 MPa. Under the action of vacuum, a layer of filter cake with a thickness of about 1.2 cm was formed on the filter cloth of the Buchner funnel, and the waste liquid in the suction filter bottle was emptied.

[0088] 2. Countercurrent exchange

[0089] Keep the vacuum degree in the filter bottle. When there is no liquid on the surface of the filter cake, slowly ...

example 3

[0100] This example uses a Buchner funnel as a separation device to simulate an industrial device to illustrate the method provided by the present invention.

[0101] 1. Formation of filter cake

[0102] The NaY zeolite (sodium oxide content is 14.5% by weight, unit cell constant is 24.66 angstroms, produced by Qilu Petrochemical Company Catalyst Factory) is mixed with deionized water to prepare a slurry with a solid content of 80 g / L, and the obtained slurry is stirred. Heated to 90°C at lower temperature, poured into a Buchner funnel, and at the same time, evacuated the filter bottle of the Buchner funnel to 0.03 MPa. Under the action of vacuum, a layer of filter cake with a thickness of about 0.8 cm was formed on the filter cloth of the Buchner funnel, and the waste liquid in the suction filter bottle was emptied.

[0103] 2. Countercurrent exchange

[0104] Keep the vacuum degree in the filter bottle. When the surface of the filter cake is about to have no liquid, immedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com