Method for producing burning free type ceramsites of magnesium substrate

A technology of ceramsite and magnesia, which is applied in the field of building materials, can solve the problems of poor corrosion resistance, moisture absorption and brine return, and high water absorption rate of magnesium cement, so as to optimize the production process, reduce product costs, and improve the water absorption rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

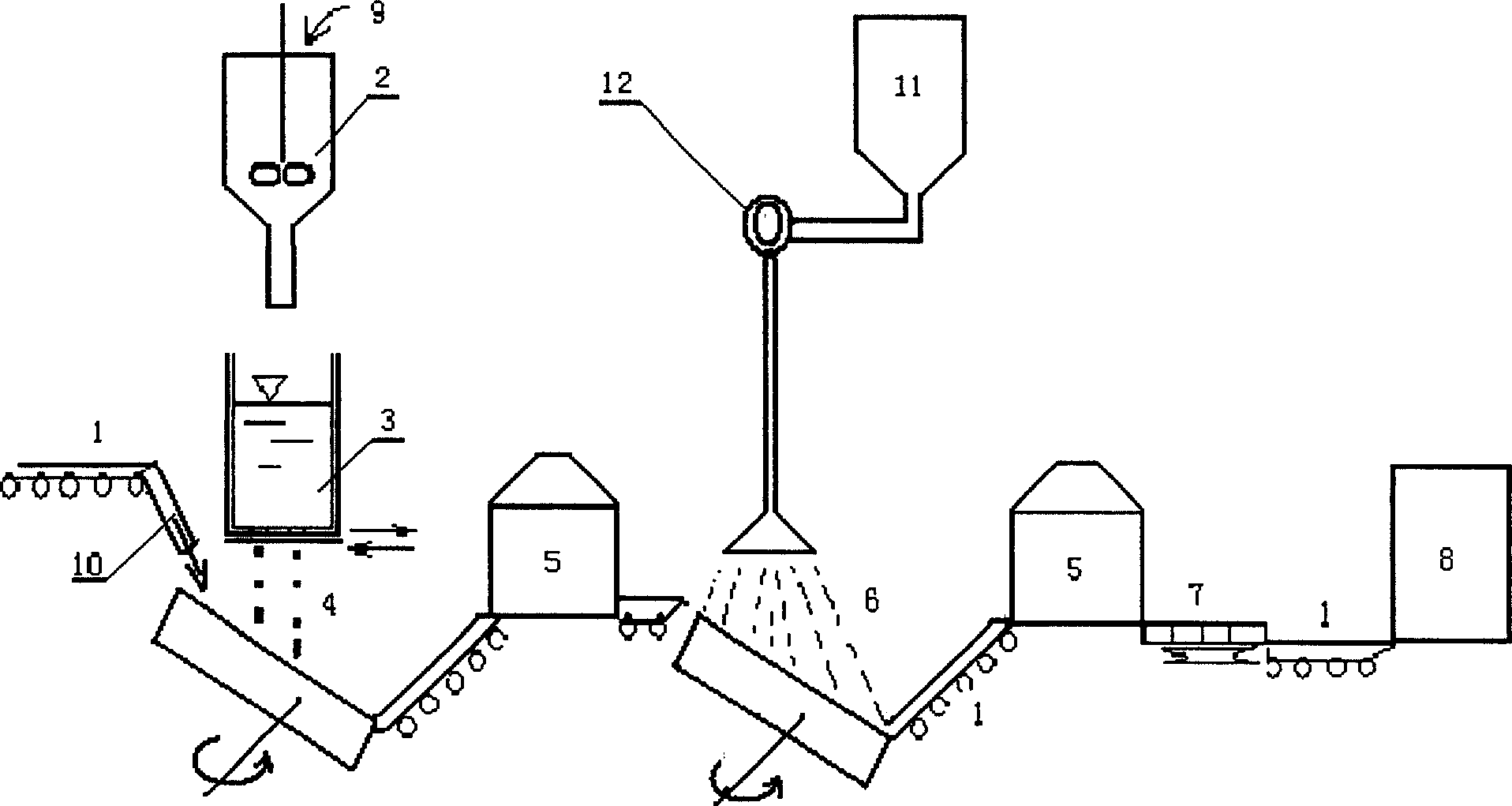

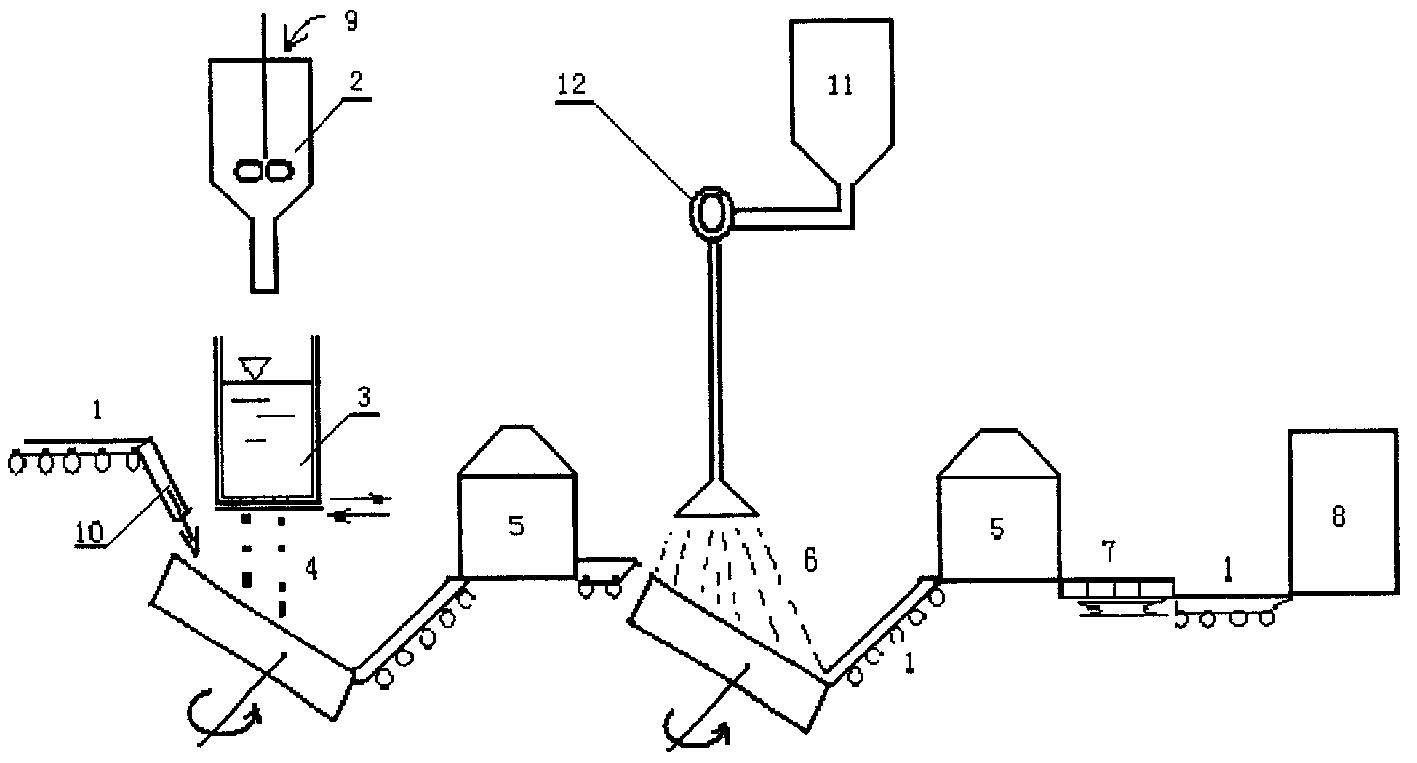

[0010] The specific production steps and the best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] Specific production steps

[0012] Step 1: Prepare the magnesia cement required for the test.

[0013] Mix magnesite and magnesium chloride by MgO / MgCl 2 = 4-6 molar ratio ingredients, adding filler fly ash, grinding in a ball mill for 2 hours, drying for later use. The grinding particles are uniform and meet the requirements of the national standard for cement.

[0014] Step 2: Preparation of magnesia ceramsite body

[0015] After mixing the magnesia cement with water, add the self-developed foaming agent to foam. The maximum volume of the sample is 200×400×600mm 3 , which is 0.144m 3 , the volume of industrial production is 2m 3 .

[0016] After the initial setting of the magnesia cement, it is dripped into a ball forming tray to form a ball to make a porous magnesia ceramsite body, which is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com