Rotor unit for electromotor and internal rotor electromotor

An inner rotor and electric motor technology, applied in the field of rotor components for electric motors and inner rotor motors, can solve the problems of impossibility, loss, and non-direct generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

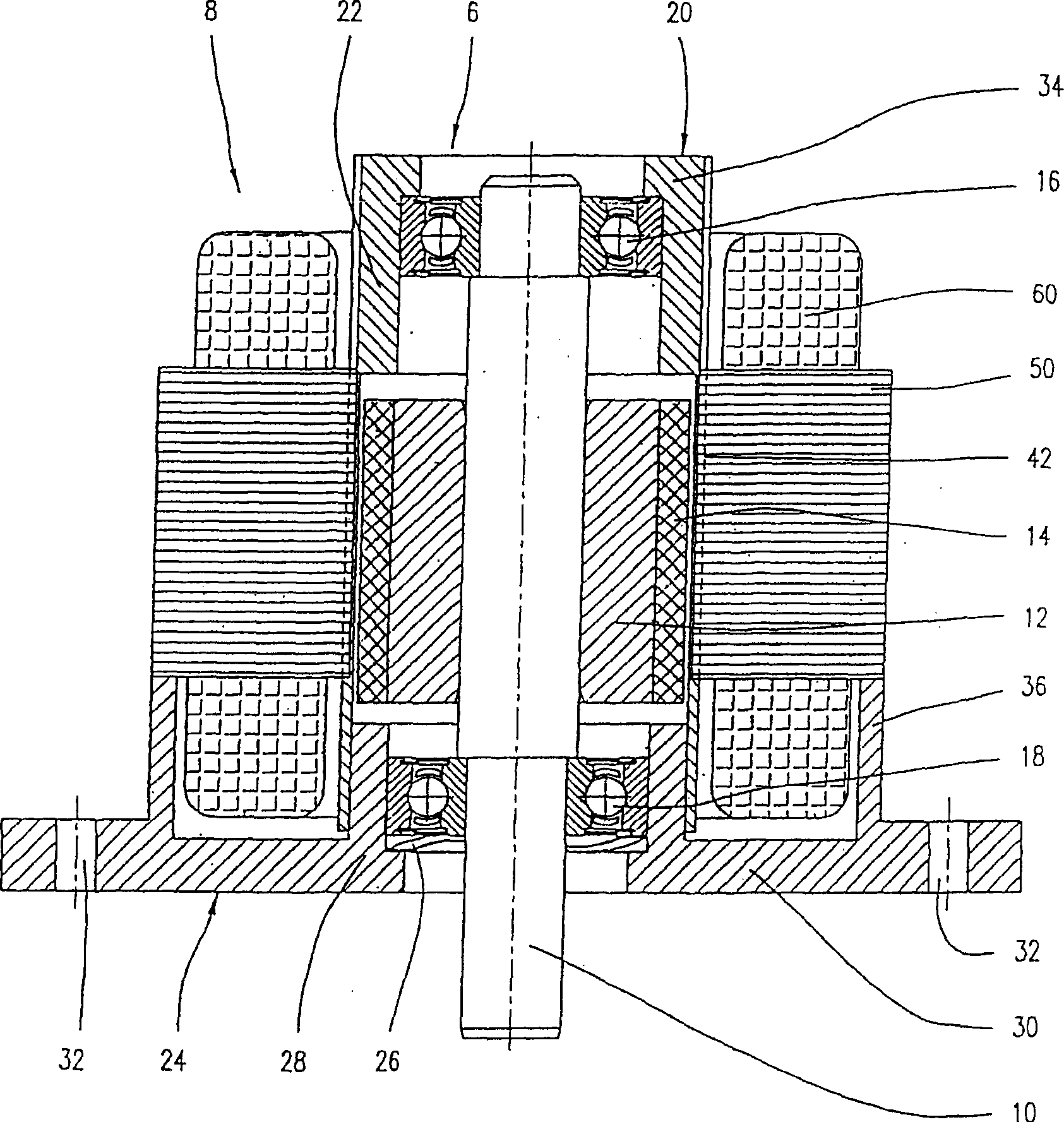

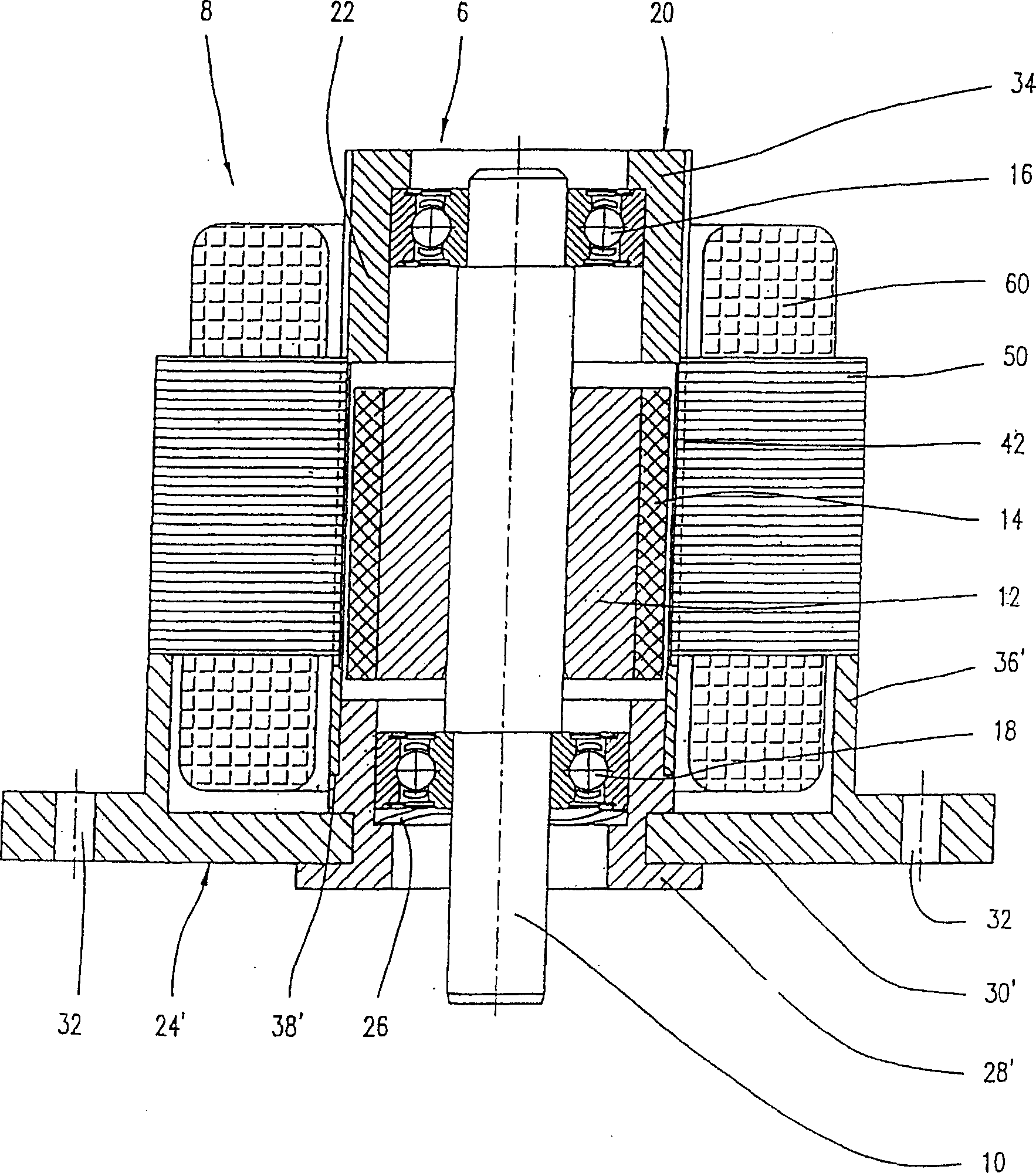

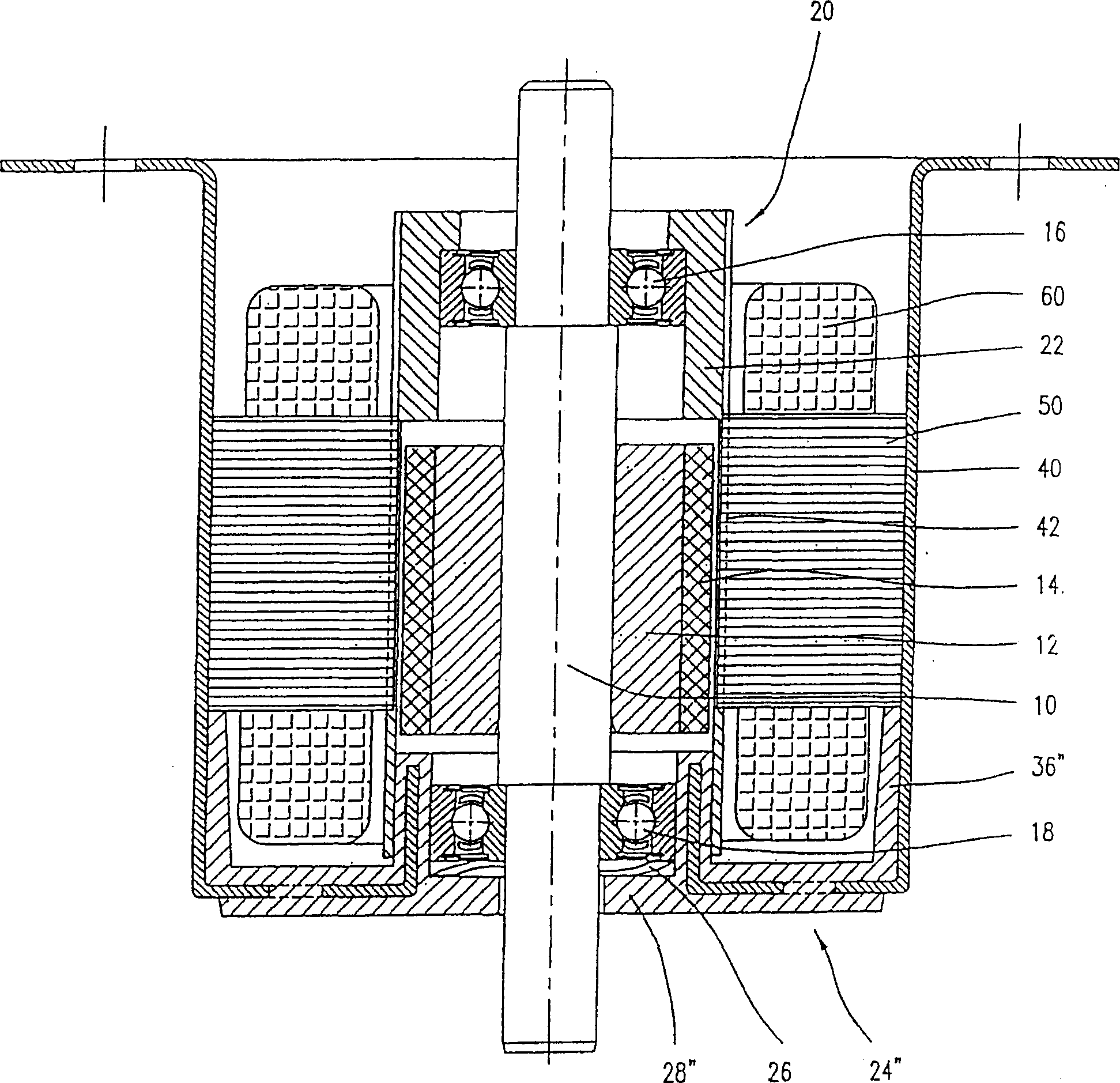

[0036] figure 1 A first embodiment of an electric motor according to the invention is shown, more specifically an inner rotor direct current motor. The electric motor includes a rotor assembly 6 and a stator 8 . The rotor assembly has a rotor shaft 10 supported by a back iron ring 12 of soft magnetic material such as steel. A segmented or annular permanent magnet 14 is attached to the back iron ring 12 . The shaft 10 is rotatable within bearings 16, 18, which are formed as needle bearings or friction bearings, more particularly ball bearings. The rotor comprising rotor shaft 10 , back iron ring 12 and one or more permanent magnets 14 is enclosed within a sleeve 20 comprising a cup portion 22 and a flange 24 . exist figure 1 In the illustrated embodiment, the flange is fabricated from a piece comprising a central cover portion 28 and a flange portion 30 . The flange portion 30 has holes 32 distributed over the periphery of the motor. In the illustrated embodiment, the cup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com