Magnetic filter

A magnetic filter, non-magnetic technology, applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of expensive filter cleaning, waste of fluid, etc., and achieve the effect of less labor and downtime and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

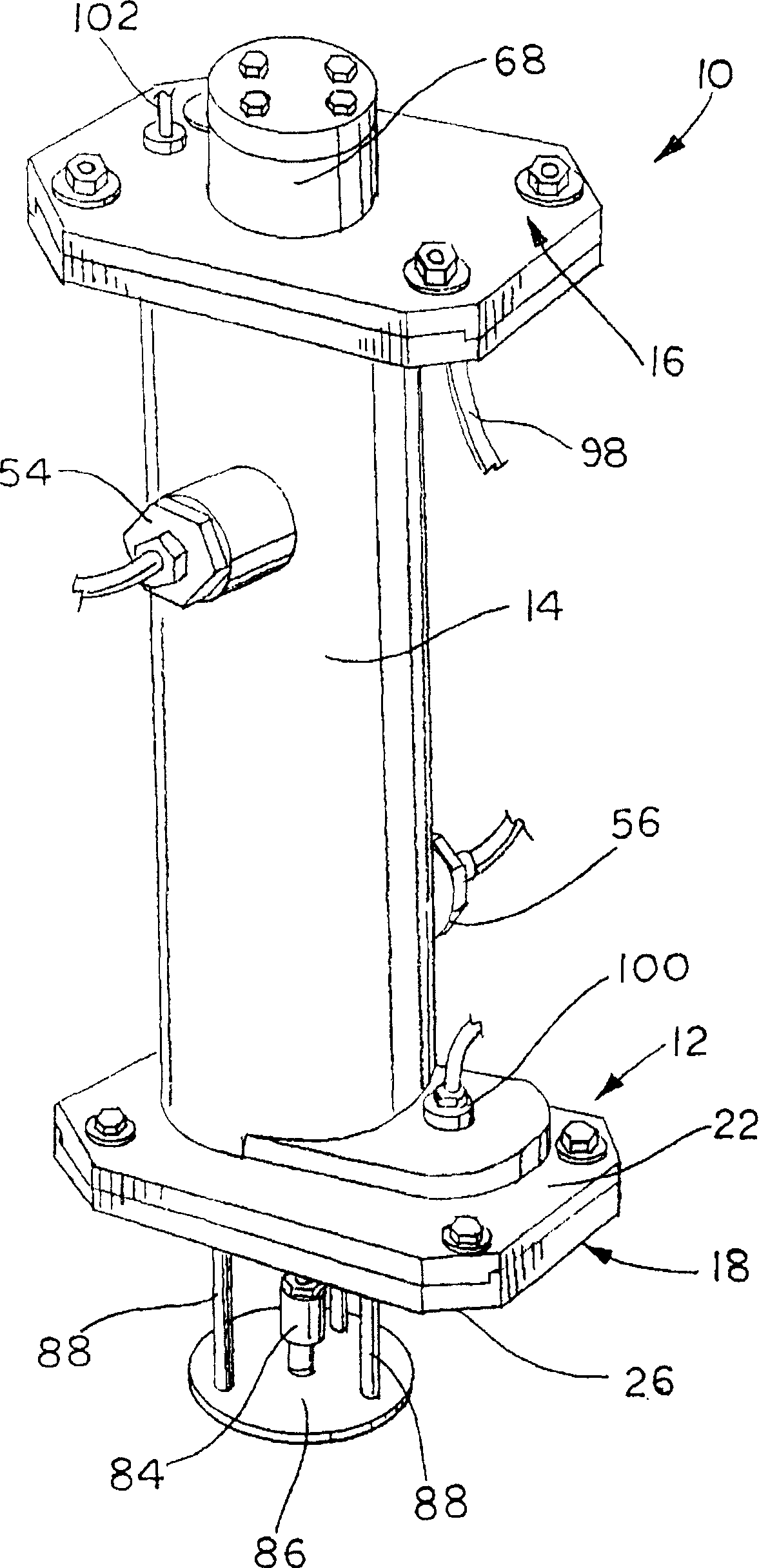

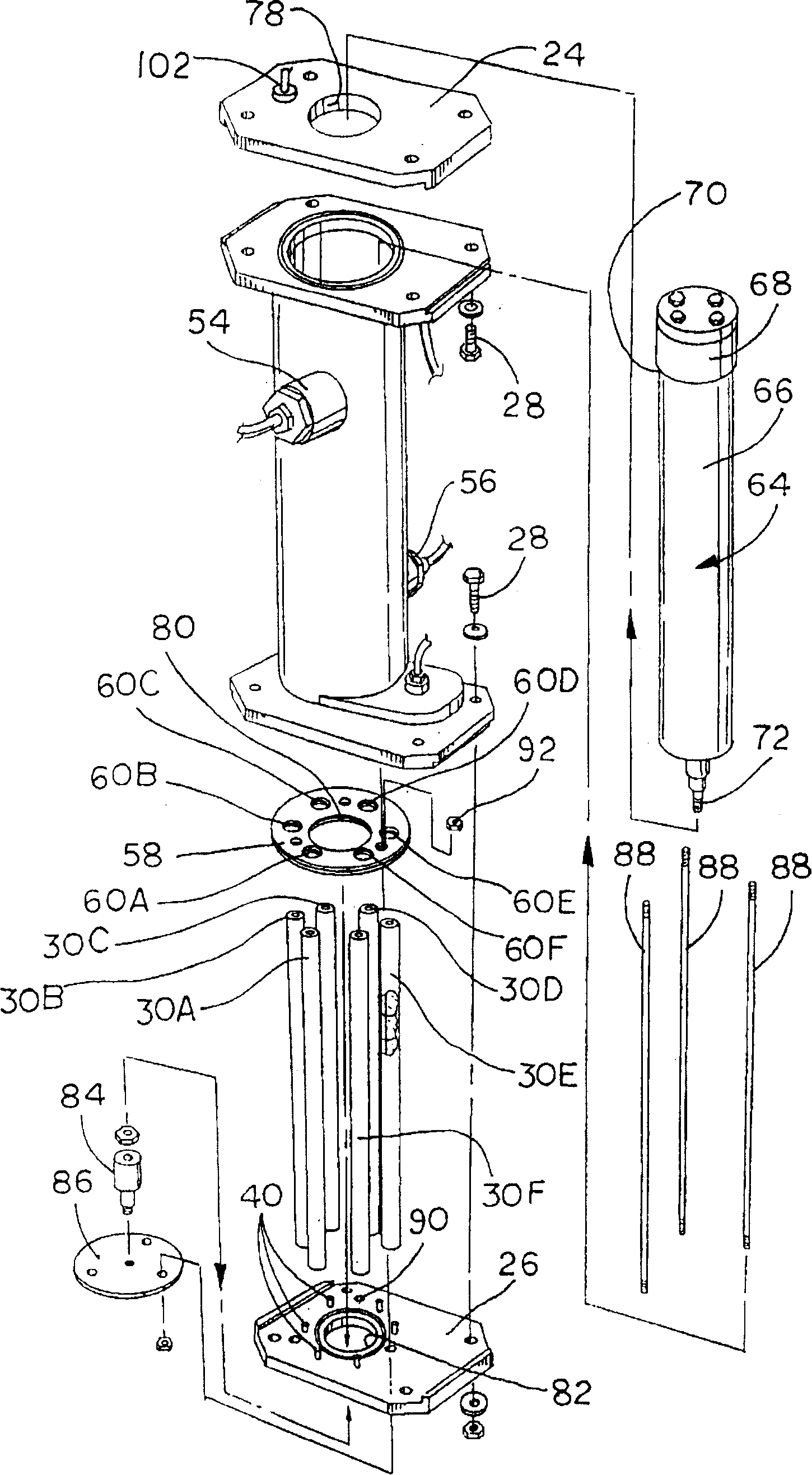

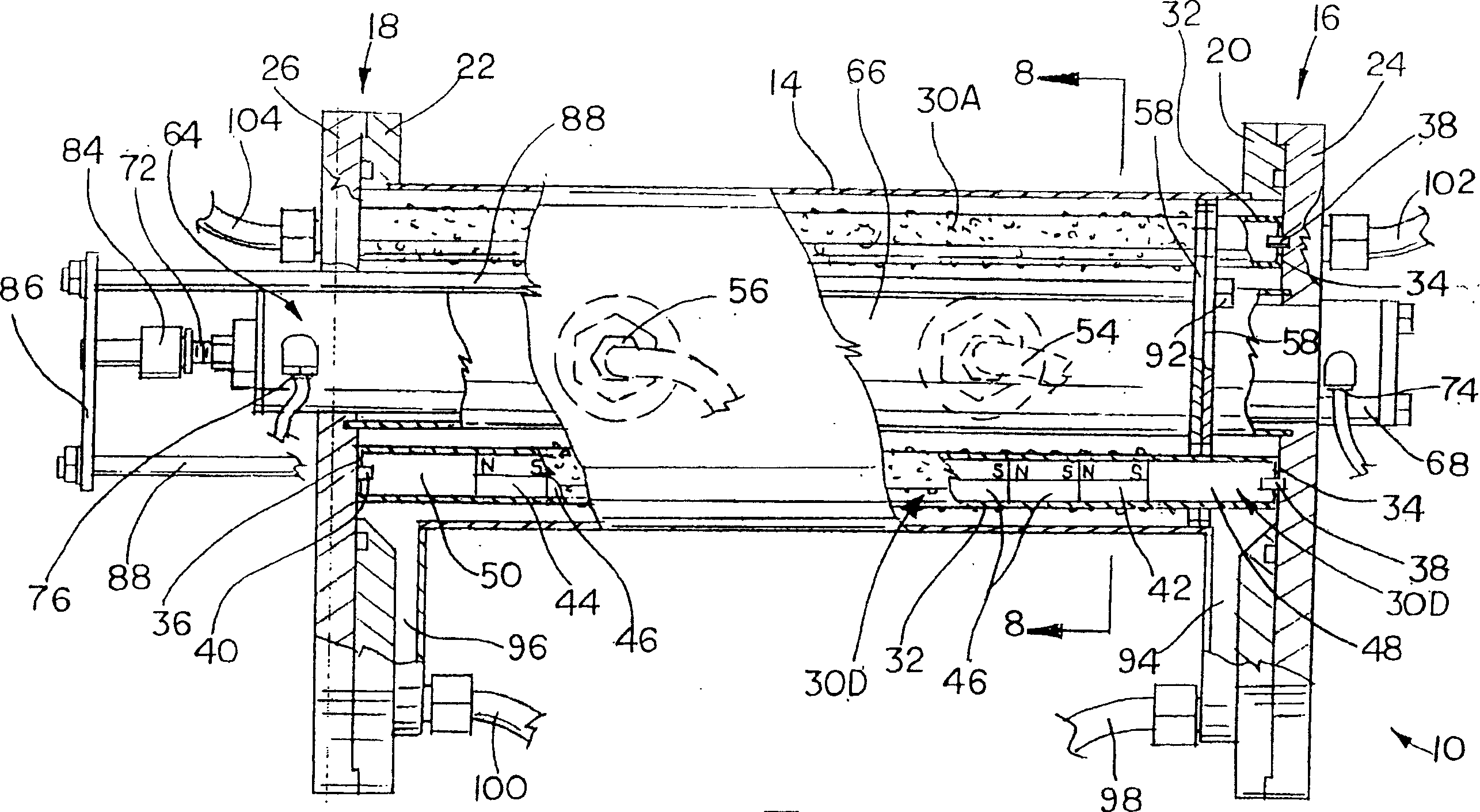

[0010] Referring now to the drawings, numeral 10 generally designates a magnetic filter made in accordance with the present invention. The magnetic filter 10 includes a housing generally indicated at 12 which includes a longitudinally extending portion 14 and a pair of transverse end portions 16, 18 mounted at opposite ends of the longitudinally extending portion 14. . Each end portion 16, 18 includes: an end plate 20, 22, each of which is fixed to opposite ends of the longitudinally extending portion 14; Each of said cover plates is fixed to a corresponding end plate 20 , 22 .

[0011] The housing portion 14 is surrounded by a plurality (in this case six) of longitudinally extending, elongated, substantially parallel magnetic elements 30A-F. Magnetic elements 30A-F each include an outer housing 32 terminating in transverse ends 34,36. Each transverse end portion 34, 36 defines an aperture that receives a respective pin 38, 40 mounted on the respective end plate 24, 26, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com