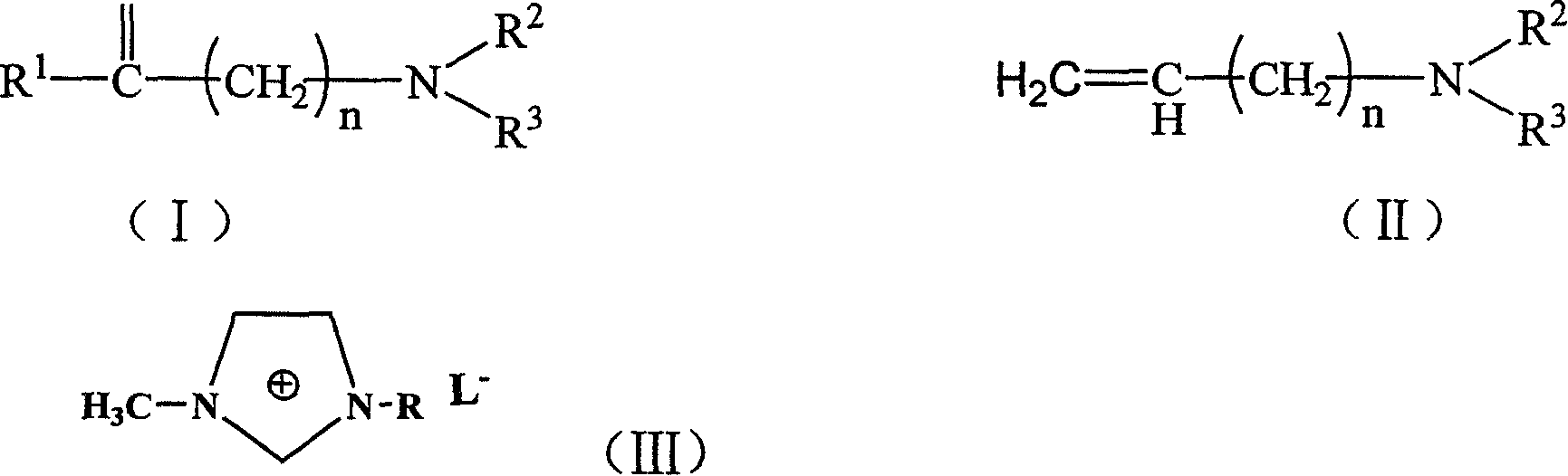

Process for preparing 2-substituted enamine or enoyl amine

An enamide and compound technology, which is applied in the field of preparation of arylalkenylamine compounds, can solve the problems of low yield, complex preparation process, environmental pollution and the like, and achieves the effects of high yield, simple preparation process and little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

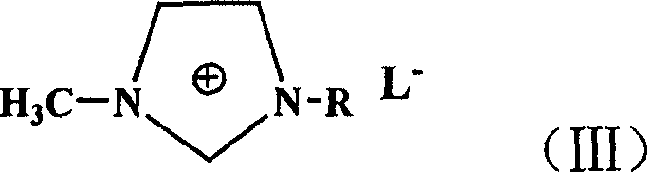

[0028] Example 1 Preparation of 1-[1-(4-acetylphenyl)vinyl]-2-pyrrolidone

[0029] 199 mg (1 mmol) of 4-bromoacetophenone, 9 mg (0.04 mmol) of palladium acetate, 33 mg (0.08 mmol) of 1,3-bis(diphenylphosphine) propane, N-vinyl- 334 mg (3 mmol) of 2-pyrrolidone, 17 mg (0.16 mmol) of triethylamine, 2 ml of 1-butyl-3-methylimidazolium tetrafluoroborate, placed in a 50 ml three-necked flask, stirred and heated , reacted at 110°C for 15 hours. After the reaction was completed, it was cooled, the reaction solution was separated to remove the ionic liquid, and extracted with dichloromethane to obtain 206 mg of the product, with a yield of 90%.

[0030] 1 H NMR (CDCl 3 )δppm: 7.92~7.94(m, 2H), 7.44~7.41(m, 2H), 5.40(s, 1H), 5.30(s, 1H), 3.60(t, J=7.0Hz, 2H), 2.60(s , 3H), 2.58(t, J=7.5Hz, 2H), 2.16(dd, J=7.0, 7.5Hz, 2H);

[0031] 1 3C NMR (CDCl 3 )δppm: 198.8, 174.8, 143.6, 140.6, 137.3, 128.9, 126.9, 110.4, 49.9, 32.5, 27.0, 19.0;

[0032] MS (m / z): 229 (M + ).

Embodiment 2

[0033] Example 2 Preparation of 10[1-(4-fluorophenyl)vinyl]-2-pyrrolidone

[0034] 175 mg (1 mmol) of 4-fluorobromobenzene, 9 mg (0.04 mmol) of palladium acetate, 33 mg (0.08 mmol) of 1,3-bis(diphenylphosphine)propane, N-vinyl-2 - 334 mg (3 mmol) of pyrrolidone, 17 mg (0.16 mmol) of triethylamine, 2 ml of 1-butyl-3-methylimidazolium tetrafluoroborate, placed in a 50 ml three-necked flask, stirred and heated, React at 125°C for 20 hours. After the reaction was completed, it was cooled, the reaction solution was separated to remove the ionic liquid, and extracted with dichloromethane to obtain 180 mg of the product with a yield of 88%.

[0035] 1 H NMR (CDCl 3 )δppm: 7.92~7.94(m, 2H), 7.06~7.01(m, 2H), 5.30(s, 1H), 5.25(s, 1H), 3.55(t, J=7.0Hz, 2H), 2.56(t , J=8.0Hz, 2H), 2.12(dd, J=7.0, 8.0Hz, 2H);

[0036] 13 C NMR (CDCl 3 )δppm: 174.8, 164.8, 162.6, 143.6, 128.3, 115.9, 109.2, 49.9, 32.3, 19.0;

[0037] MS (m / z): 205 (M + ).

Embodiment 3

[0038] Example 3 Preparation of 1-[1-(4-methoxyphenyl)vinyl]-2-pyrrolidone

[0039]187 mg (1 mmol) of 4-bromoanisole, 9 mg (0.04 mmol) of palladium acetate, 33 mg (0.08 mmol) of 1,3-bis(diphenylphosphine)propane, N-vinyl- 334 mg (3 mmol) of 2-pyrrolidone, 17 mg (0.16 mmol) of triethylamine, 2 ml of 1-butyl-3-methylimidazolium tetrafluoroborate, placed in a 50 ml three-necked flask, stirred and heated , reacted at 115°C for 20 hours. After the reaction was completed, it was cooled, the reaction solution was separated to remove the ionic liquid, and extracted with dichloromethane to obtain 198 mg of the product, with a yield of 91%.

[0040] 1 H NMR (CDCl 3 )δppm: 7.06~6.97(m, 2H), 6.75~6.47(m, 2H), 4.98(s, 1H), 4.87(s, 1H), 3.45(s, 3H), 2.19(dd, J=7.0, 8.0Hz, 2H), 2.10(t, J=8.0Hz, 2H), 1.76(m, 2H);

[0041] 13 C NMR (CDCl 3 )δppm: 172.8, 160.8, 143.6, 127.3, 127.0, 126.8, 114.9, 114.3, 107.2, 55.9, 41.5, 32.8, 19.0;

[0042] MS (m / z): 217 (M + ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com